Fiber Bragg Grating Shape Sensor Fixture

A fiber grating and sensor technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of low precision, expensive equipment, difficult packaging, etc., and achieve improved stability and reliability, improved measurement accuracy, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

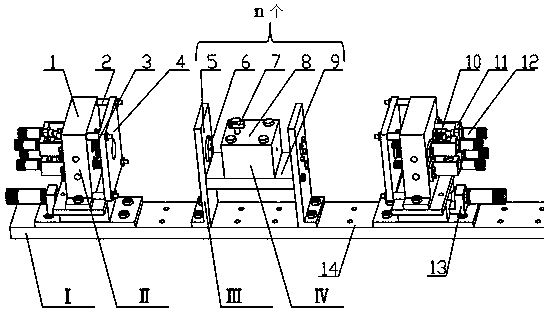

[0023] see Figure 1~Figure 4 , this fiber grating packaging fixture includes a base (I), a fiber grating axial adjustment device (II) with opposite directions on the left and right sides, n fiber grating-memory alloy wire positioning devices (III) in the middle and n adhesives The encapsulation device (IV) is used for encapsulation of n grid points, characterized in that: the left and right fiber grating axial adjustment devices (II) and the n fiber grating-memory alloy wire positioning devices (III) are all installed with bolts On the base, the n adhesive packaging devices (IV) are respectively installed on the n optical fiber grating-memory alloy wire positioning devices (III).

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, and the features are as follows:

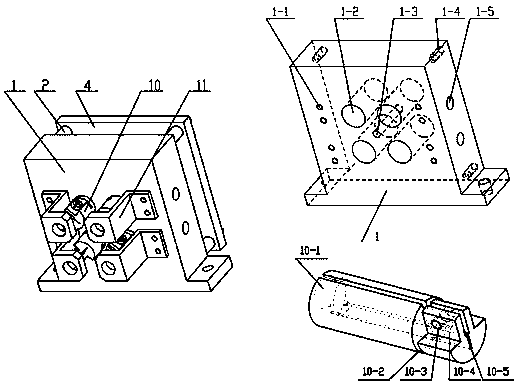

[0026] The structure of the fiber grating axial adjustment device (II) is: a one-dimensional mobile platform (13) is installed on the base (I), and the one-dimensional mobile platform (13) is connected with an adjustment plate (1); four Cylindrical sliders (10) are respectively placed in the matching slider holes (1-2) on the adjustment plate (1), and each slider (10) has a groove (10-5) along the longitudinal direction , for clamping the fiber grating, two recesses (10-4) are cut out at the rear end of the slider (10), and a fastening threaded hole (10-3) for clamping the fiber grating is drilled on one recess, Carve a transverse groove (10-5) on the front of the concave table to the longitudinal groove where the fiber grating is placed, so that the part clamping the fiber grating can be deformed enough; the front end of the adjustment plate (1) is connected with four connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com