Quick loading and unloading box car body

A car body, fast technology, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of not being able to adapt to fast loading and unloading operations, not being able to load large cargo, and small door opening size, etc., to achieve improved Loading and unloading efficiency, simple structure, and the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

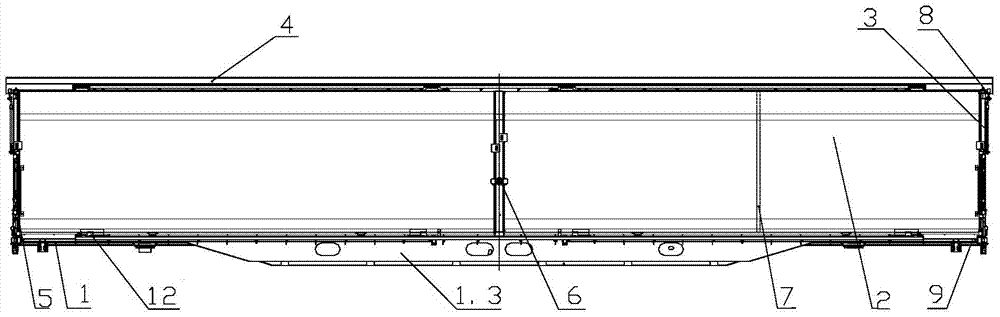

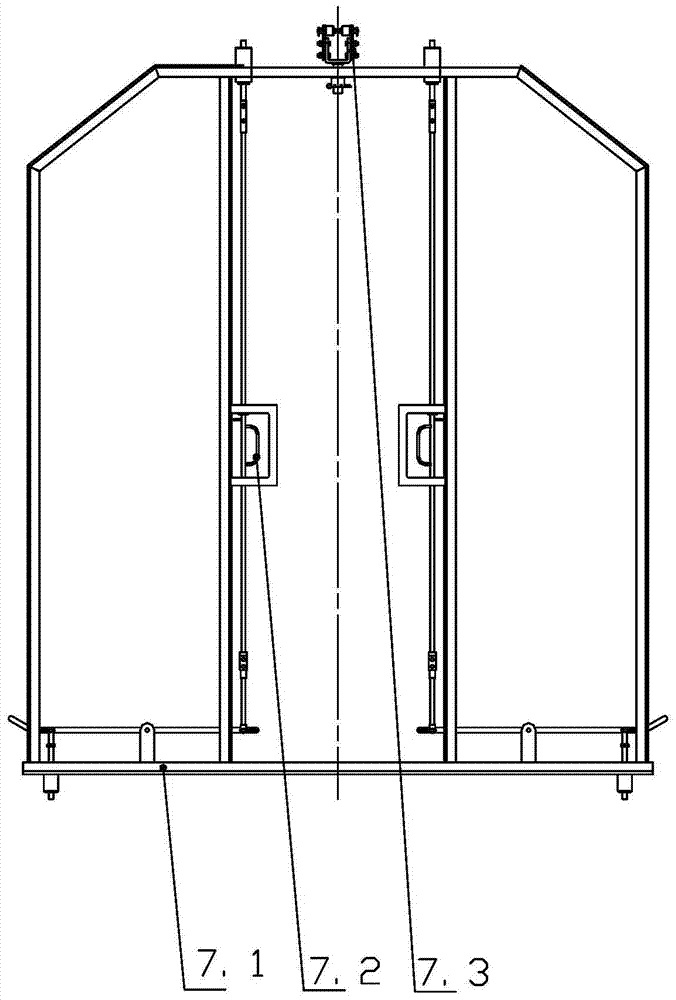

[0051] As shown in the figure, the car body of the quick loading and unloading boxcar includes an underframe 1, a movable side wall 2, an end opening and closing mechanism 3, a roof 4, an end wall 5, an intermediate pressing device 6, a movable partition wall 7, an upload The moving shaft is composed of 8, the lower transmission shaft is composed of 9, the upper track is composed of 10 and the lower track is composed of 11;

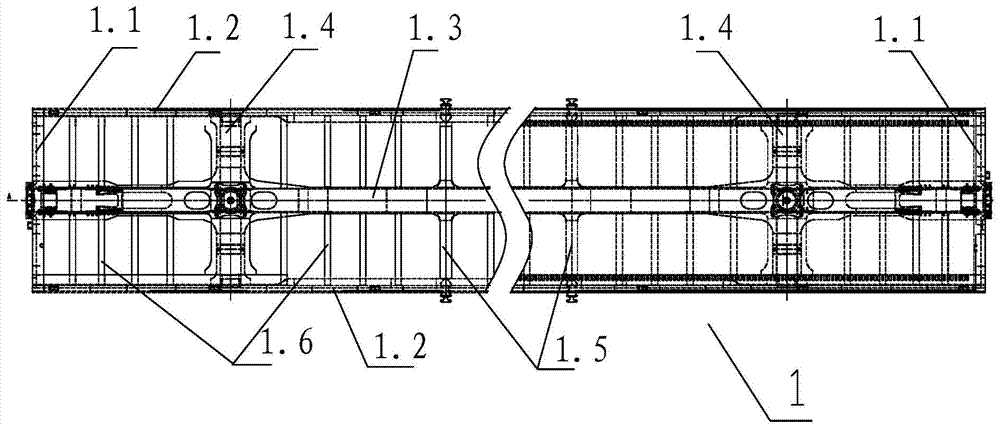

[0052] The chassis 1 is composed of end beams 1.1, side beams 1.2, middle beams 1.3, corbel beams 1.4, large beams 1.5 and small beams 1.6 connected to each other by welding to form a whole, and the steel floor is installed on the upper surface of the whole chassis 1 by welding , the steel floor is made of high-strength patterned steel plate;

[0053] The number of end beams 1.1 is two, which are respectively located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com