Pulse-free discharging screw rod device

A discharge screw and rod device technology, applied in the field of conveying machinery, can solve the problems of powder conveying discontinuity, non-quantification, pulsation, etc., and achieve the effect of avoiding pulse discharge and reducing the filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

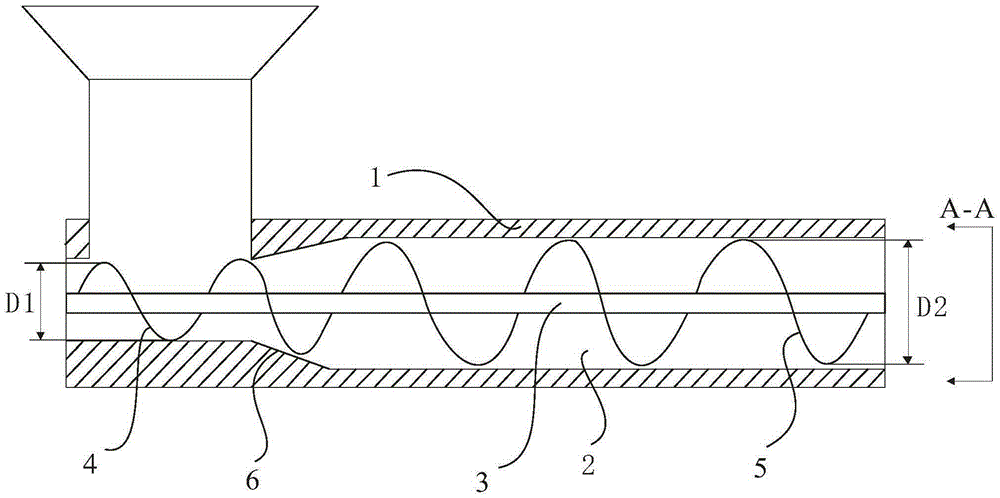

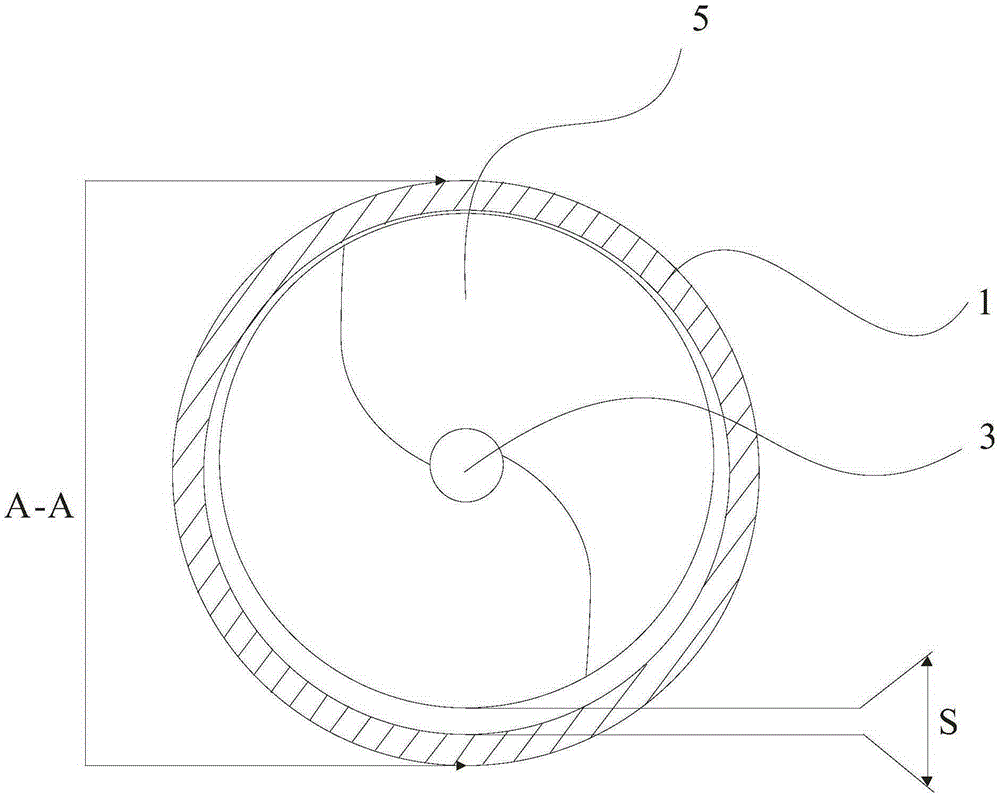

[0013] Such as figure 1 Shown is a non-pulse discharge screw device, including a hopper and a screw conveyor; the screw conveyor includes a tube wall 1 and a lumen 2; a screw 3 is installed in the lumen 2, and the screw Rotating leaves are installed on the rod 3.

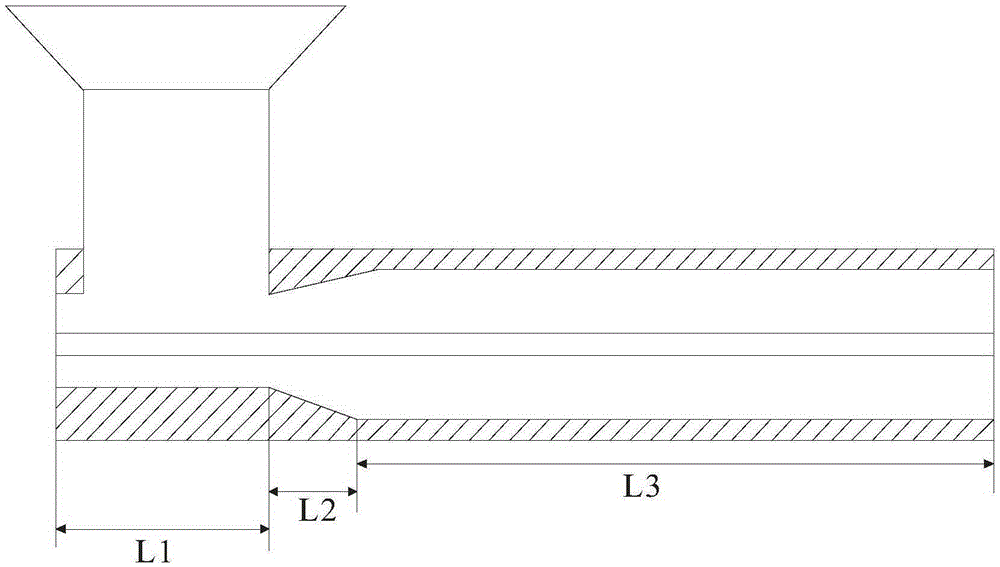

[0014] Such as figure 2 As shown, the pipe wall 1 is divided into feeding section L1, transition section L2 and feeding section L3 in turn according to the conveying direction; the feeding section L1 is located below the feeding hopper; the lumen of the feeding section L1 The inner diameter H1 is smaller than the inner diameter H2 of the lumen of the feeding section L3; the part of the tube wall 1 where the thickness of the tube wall gradually decreases between the feeding section L1 and the feeding section L3 is the transition section L2, so The inner diameter of the lumen 2 gradually increases in the transition section L2. The transition section L2 is preferably arranged as a slope 6 . This design of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com