A load transfer platform with controllable weight reduction by electromagnetic force

An electromagnetic force and platform technology, applied in conveyors, non-mechanical conveyors, transportation and packaging, etc., can solve problems such as bulky, difficult to operate, and difficult to achieve high-precision movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

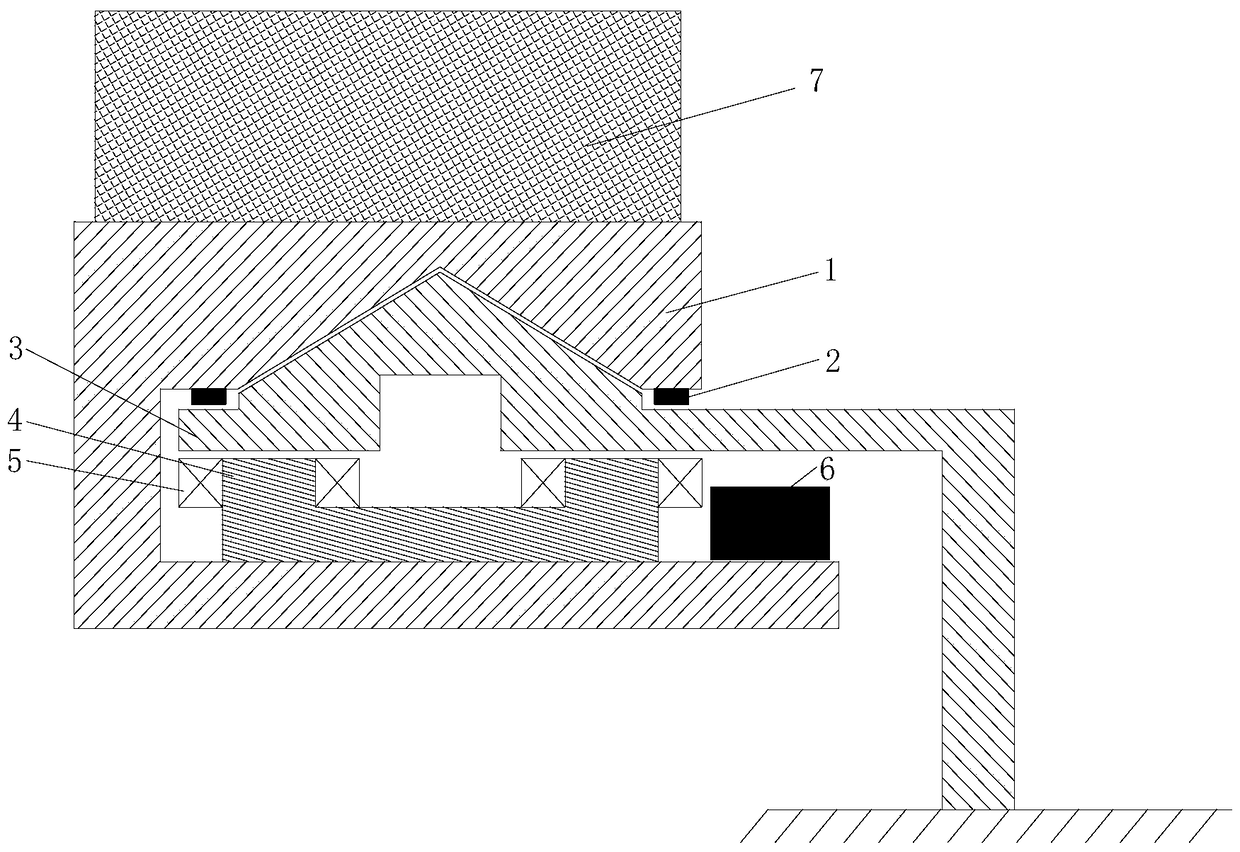

[0013] The structure of the two electromagnets is exactly the same, and they are installed symmetrically at the front and rear ends of the loading platform. The electromagnet is U-shaped, and the four electromagnet coils are respectively wound on the four U-shaped columns of the electromagnet. The number of turns and the winding direction of the coil are exactly the same. .

[0014] The parameters of the four pressure sensors are exactly the same, and they are installed symmetrically on four points, front, rear, left, and right at the bottom of the loading platform. For the installation positions, see figure 1 .

[0015] The pressure sensor can detect the pressure of the loading platform on the track, and the detection values of the four pressure sensors are sent to the solenoid coil control unit, and the control unit controls the current output to the four electromagnet coils according to the detection value, and finally makes the four pressure The detection value of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com