A kind of synthetic method of uv/moisture dual curing polymer

A polymer and dual-curing technology, applied in the direction of adhesives, etc., can solve the problems of affecting production efficiency and high curing energy, and achieve the effects of low price, high transparency and good moisture curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023]

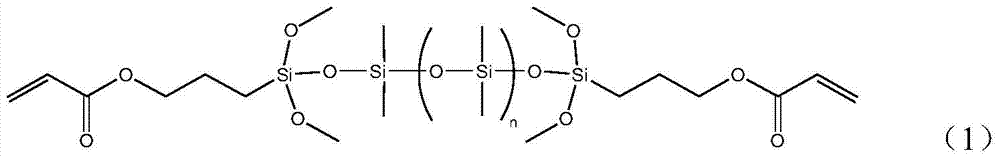

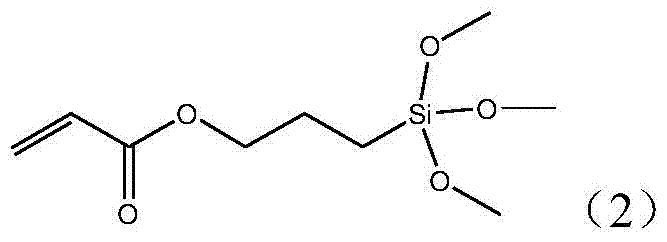

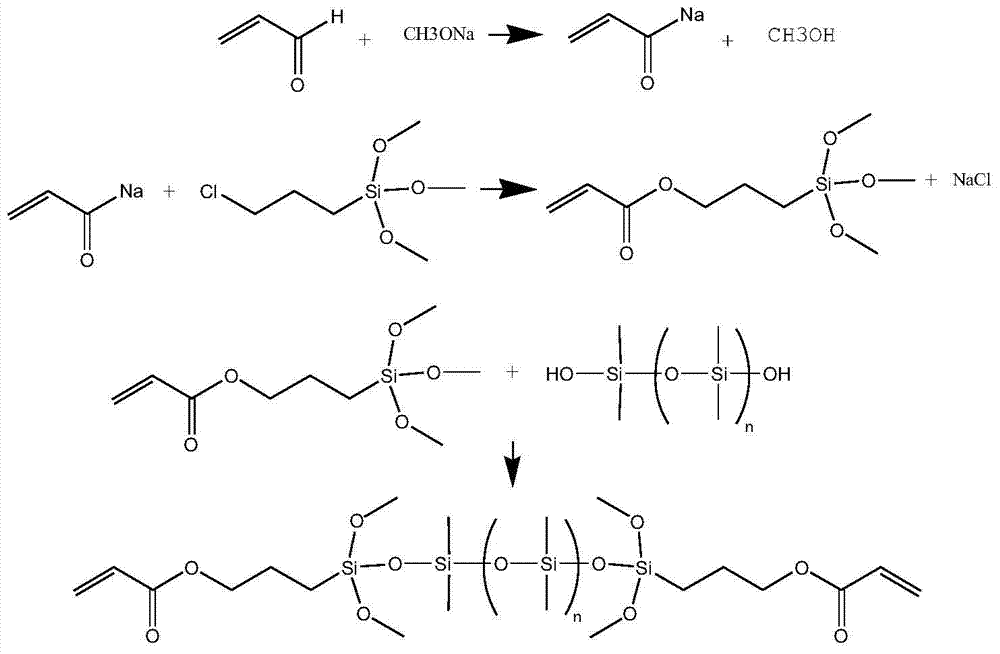

[0024] 1) Synthesis of acryloxypropyltrimethoxysilane

[0025] Add 27.3g of sodium methoxide methanol solution and 15g of toluene into the three-necked flask, start stirring at 250r / min, pass condensed water, and add 10.9g of acrylic acid dropwise at room temperature, after 30 minutes, add 0.075g of BHT and 0.075g of PTZ , heated up to 85°C, distilled methanol, steamed to a liquid temperature of 100°C, continued the reaction for 4 hours and then lowered to room temperature, added 1.5g of tetramethylammonium bromide and 30.1g of chloropropyltrimethoxysilane and raised the temperature to a liquid temperature of 115°C. Reflux for 6 hours, lower to room temperature, filter, take the filtrate and distill it under reduced pressure, take 0.4mm Hg (lit.) distillate at 68°C as 32.5g of acryloyloxypropyltrimethoxysilane, the yield is 91.67%, seal it up and store it for later use ;

[0026] 2) Heat the oil bath to 50°C, add 32.5g of acryloxypropyltrimethoxysilane and 2500g o...

example 2

[0028]

[0029] 1) Synthesis of acryloxypropyltrimethoxysilane

[0030] Add 32.76 g of sodium methoxide methanol solution and 18 g of toluene to the three-necked flask, start stirring at 250 r / min, pass condensed water, and add 13.08 g of acrylic acid dropwise at room temperature, and the dropwise addition is completed in 35 minutes. React for 1 hour, heat up to 85°C, and distill methanol , steamed to a liquid temperature of 100°C, continued to react for 4 hours and then cooled to room temperature, added 1.8g of tetramethylammonium bromide and 36.12g of chloropropyltrimethoxysilane to raise the temperature to a liquid temperature of 115°C, refluxed for 6 hours, and cooled to room temperature. After filtration, the filtrate was distilled under reduced pressure, and the 68°C 0.4 mm Hg (lit.) fraction was obtained as 19.5 g of acryloyloxypropyltrimethoxysilane, with a yield of 45.84%. Sealed and sealed for use;

[0031] 2) Heat the oil bath to 50°C, add 19.5g of acryloxypropy...

example 3

[0033]

[0034] 1) Synthesis of acryloxypropyltrimethoxysilane

[0035] Add 27.5g of sodium methoxide methanol solution and 15g of toluene into the three-necked flask, start stirring at 250r / min, and pass condensed water. At room temperature, add 11.0g of acrylic acid dropwise, and the dropwise addition is completed in 30 minutes. After reacting for 1 hour, add 0.075g of BHT and 0.075g of PTZ, raise the temperature to 85°C, distill methanol, and steam to the liquid temperature of 100°C. g of tetramethylammonium bromide and 30.3g of chloropropyltrimethoxysilane were heated to a liquid temperature of 115°C, refluxed for 6 hours, and then cooled to room temperature. Filtrate, distill the filtrate under reduced pressure, take 0.4mm Hg (lit.) distillate at 68°C to obtain 32.7g of acryloyloxypropyltrimethoxysilane, yield 92.23%, seal and store for later use;

[0036] 2) Heat the oil bath to 50°C, add 32.7g of acryloxypropyltrimethoxysilane and 2500g of hydroxy silicone oil into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com