Construction method for adjusting steel plate embedded parts to reach design and construction accuracy

A construction method and technology of pre-embedded parts, which are applied in the direction of construction and building structure, can solve the problems of low installation accuracy, cumbersome, and difficult to meet the needs of efficient, precise and accurate construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

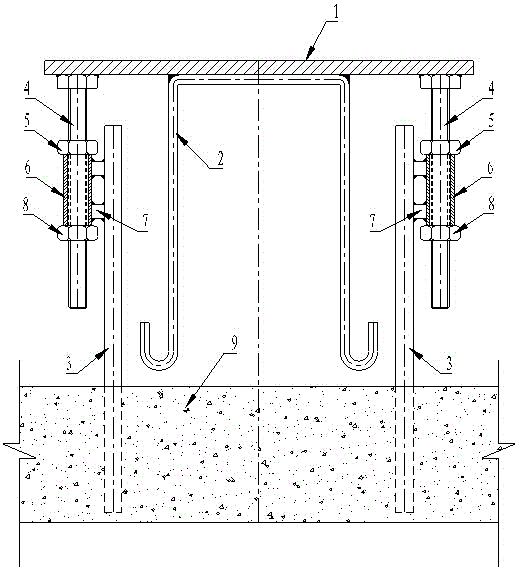

[0010] Such as figure 1 As shown, the construction method for adjusting the steel plate embedded parts to achieve the design and construction accuracy of the present invention is: when installing each embedded steel plate 1, the lower surface of the embedded steel plate with the embedded steel plate anchor bar 2 is close to 4 right angles Weld four screw rods 4 at the bottom of the right angle. Each screw rod is first screwed into the leveling nut 5, and then penetrated into the sleeve 6. The sleeve 6 is welded to the fixed steel bar 3 through the sleeve fixed steel plate 7. Each screw is used The sleeve fixing steel bar 3 used to fix the sleeve is placed directly below the right angle of the position where the embedded steel plate is installed. The sleeve fixing steel bar is anchored on the base surface before the embedded steel plate is installed. Measure and adjust each leveling nut so that the The elevation of the top surface of the buried steel plate and the accuracy of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com