Differential hydraulic cylinder control loop

A control circuit and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of slow hydraulic cylinder extension speed, non-reusable, low work efficiency, etc., to improve work efficiency , increase the extension speed, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

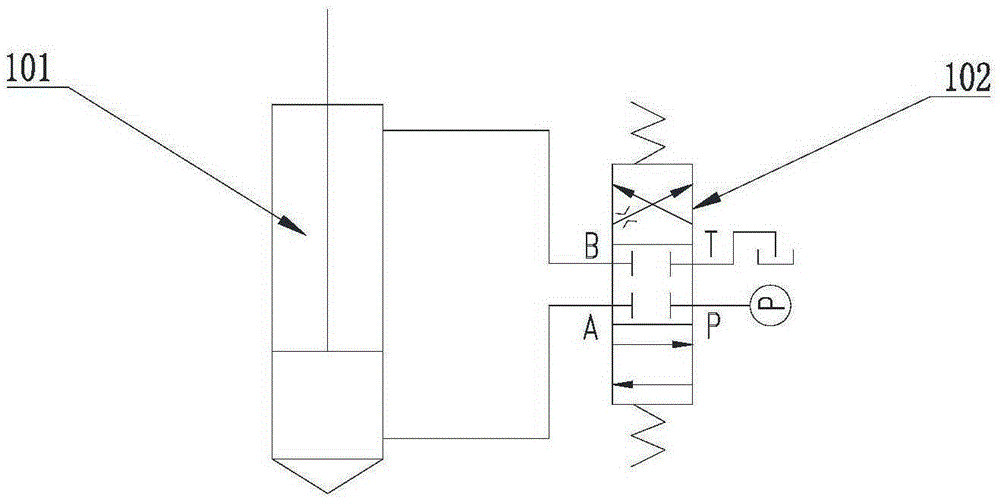

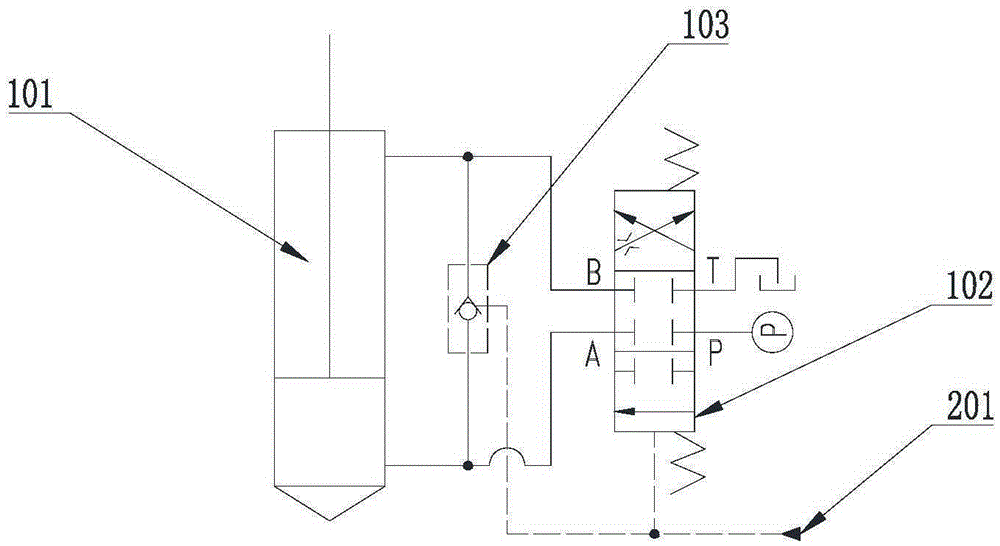

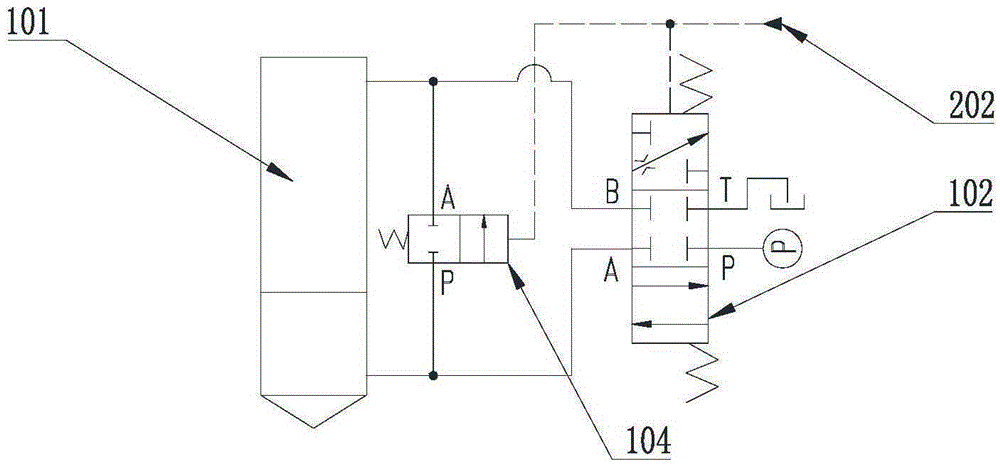

[0018] like Figure 4 As shown, the present invention provides a differential hydraulic cylinder control circuit, including a differential hydraulic cylinder 101, a directional control valve 301, a first check valve 105, a second check valve 106, a variable throttle valve 107, and a flow regeneration valve 108, the differential connection control valve 109; the two oil outlets A and B of the directional control valve 301 communicate with the rodless cavity and the rod cavity of the differential hydraulic cylinder 101 respectively to form a main circuit; the differential connection control valve 109. The second one-way valve 106 constitutes a differential connection control branch; the variable throttle valve 107, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com