Movable tailstock sleeve

A tailstock sleeve and movable technology, which is applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of low work efficiency, long time consumption, and high labor intensity, so as to improve work efficiency , Improve the effect of extending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

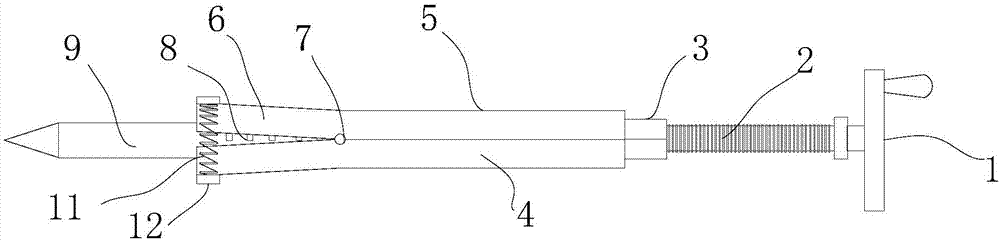

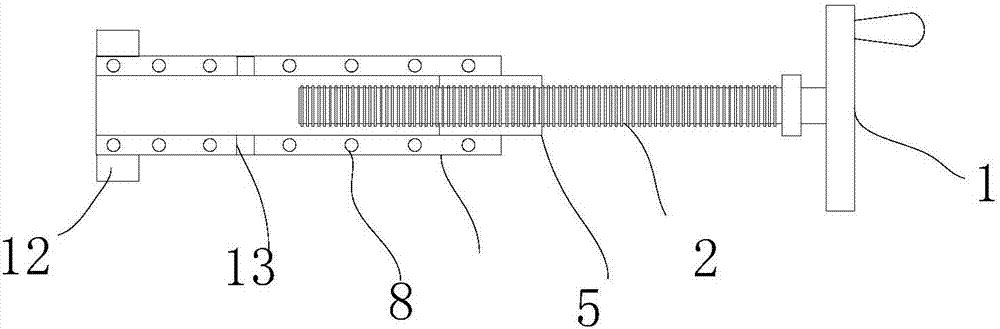

[0012] Such as figure 1 As shown, it includes a sleeve, a nut 3, a screw 2, a top 9 and a hand wheel 1. The nut 3 is fixedly installed in the sleeve. There is a threaded hole in the middle of the nut 3. The screw 2 passes through the threaded hole in the middle of the nut 3 and extends In the sleeve, the top 9 is installed at the front end of the sleeve, the rear end of the top 9 is against one side of the screw, and the handwheel 1 is fixedly installed on the outer end of the screw 2. The sleeve includes a first sleeve 5 And the second sleeve 4, movable assembly between the first sleeve 5 and the second sleeve 4, the outer ends of the first sleeve 5 and the second sleeve 4 are respectively provided with a convex portion 6, and the two convex portions 6 is bent outward, and an extrusion cavity is formed between the opposite surfaces of the two convex parts 6. An arc-shaped positioning groove 13 is provided on the opposite surfaces of the tail ends of the two convex parts 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com