Prefabricated directly buried insulation pipe rigid polyurethane concentric device and its manufacturing method

A rigid polyurethane, prefabricated direct-buried technology, applied in the direction of heat preservation, pipe protection through heat insulation, pipe protection, etc., can solve the problems of destroying the heat preservation effect of polyurethane and reducing the heat preservation temperature, and achieve the same heat preservation effect and the same thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

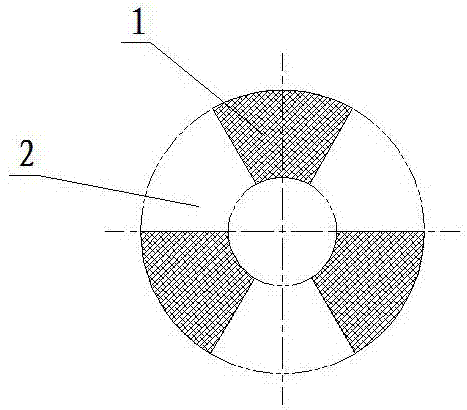

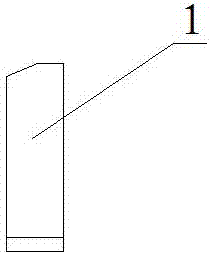

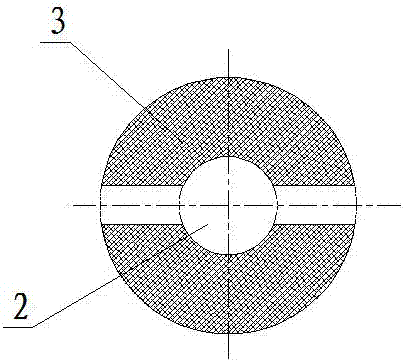

[0024] A prefabricated directly buried insulation pipe rigid polyurethane concentric device, its composition includes: a rigid polyurethane substrate body 2, the rigid polyurethane substrate body is cylindrical, and the front end surface of the rigid polyurethane substrate is used as a reference Divided into 3 supporting concentric blocks A1 or divided into 2 supporting concentric blocks B3, the 3 supporting concentric blocks A are the same block structure, and the 2 supporting concentric blocks B are symmetrical C-shaped cards Set of structures.

Embodiment 2

[0026] According to the prefabricated directly buried insulation pipe rigid polyurethane concentric device described in embodiment 1, the outer surface and inner surface of the three described supporting concentric device blocks A are concentric circle structures, and the outer surfaces of the two described supporting concentric device block B Concentric circle structure with inner surface.

Embodiment 3

[0028] According to the prefabricated direct buried insulation pipe rigid polyurethane concentric device described in embodiment 1 or 2, the supporting concentric device block A and the supporting concentric device block B are made of high-density rigid polyurethane plastic foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com