Liquid ring maintaining device used for liquid conveying

A liquid ring, high-speed rotation technology, used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as difficult application of liquid ring transportation engineering, and achieve the effect of reducing pipeline energy consumption and flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

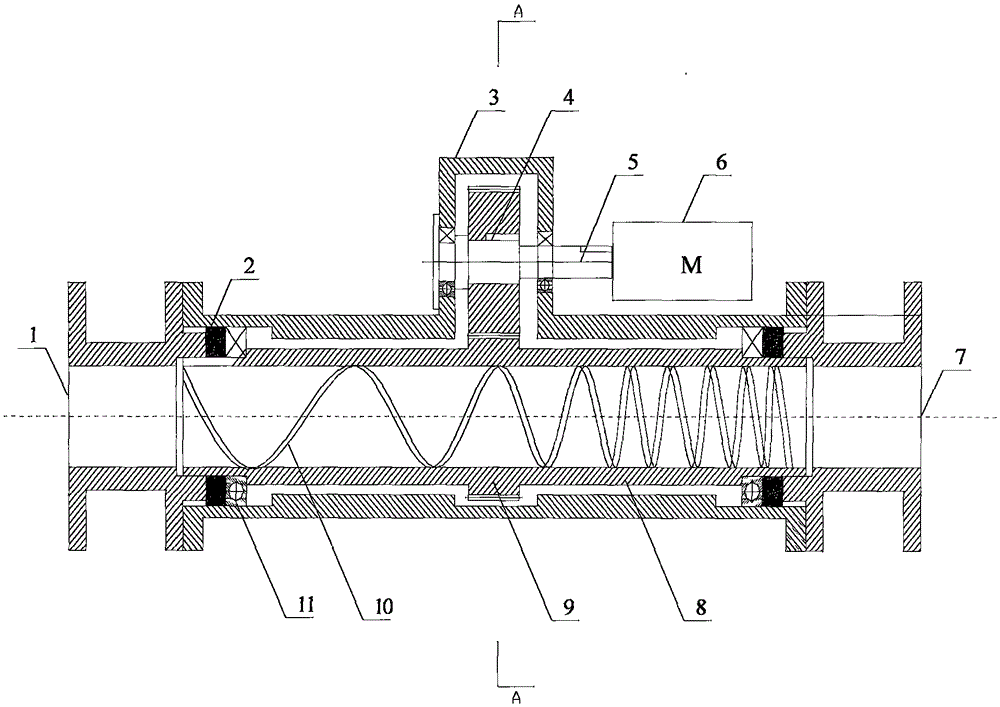

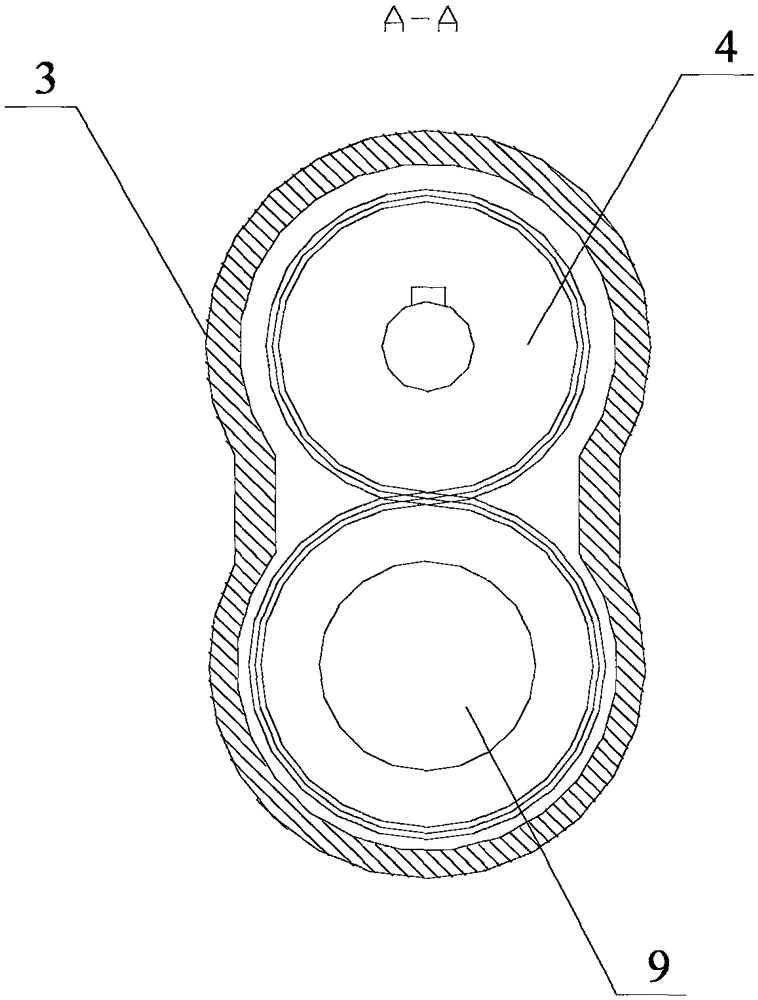

[0013] Below in conjunction with accompanying drawing and example the present invention will be further described:

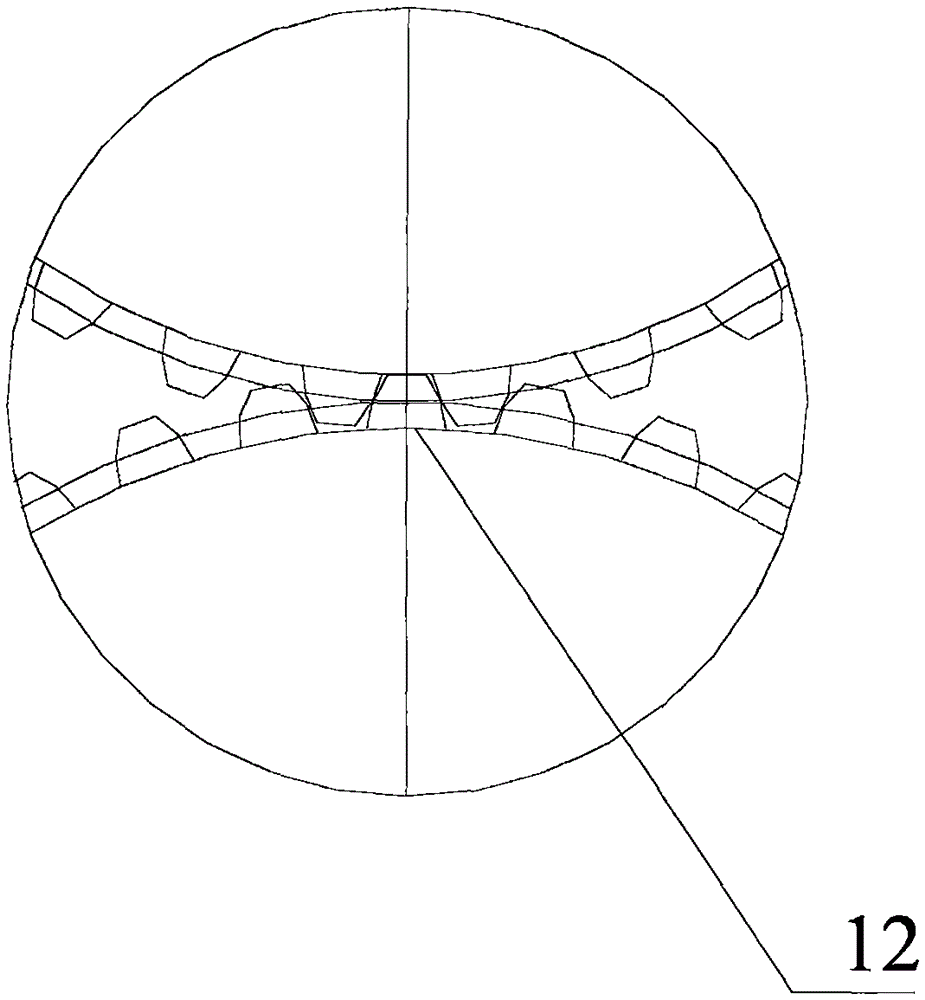

[0014] like Figure 1-3 As shown, the liquid ring maintenance device for liquid ring transportation provided by the present invention includes an inlet flange 1, a sealing member 2, a protective casing 3, a driving gear 4, a transmission shaft 5, a motor 6, an outlet flange 7, a high-speed rotary Drum 8, driven gear 9, helical blade 10, support member 11, the motor 6 is connected with the driving gear 4 through the transmission shaft 5, so that the two rotate at the same angular speed; the middle part of the high-speed drum 8 is connected with the driven gear 9 are seamlessly connected and rotate coaxially at the same angular velocity; the driven gear 9 is meshed with the driving gear 4 through the external gear and rotates at the same linear velocity; the inner diameter of the high-speed drum 8 is consistent with the inlet flange 1 and the outlet flange 7 have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com