A kind of polymer for crude oil pour point depressing and application thereof

A technology for high molecular polymer and crude oil pour point depressant, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of dependence on imports and the insufficiency of the variety and quantity of domestic crude oil pour point depressants, and reduce transportation costs. , The effect of improving low temperature fluidity and reducing pipeline energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Synthesis of styrene-maleic anhydride high molecular polymer for crude oil pour point depressing

[0027] (1) Preparation method

[0028] Add 11.8 g (0.12 mol) of maleic anhydride and 100 mL of toluene into a 250 mL three-neck flask, blow nitrogen, stir and heat. When the temperature rises to 70 °C, under constant stirring, add 13.0 mL (0.12 mol) of styrene and 50 mL of azobisisobutyronitrile (0.1215 g) in toluene (benzoyl peroxide can also be used as the initiator), Add it to the reaction flask three times, and finish adding dropwise within 30 min. The temperature was controlled at about 80 °C, and the heating was stopped when the reactant became thick and the stirring was difficult, which lasted about 2 h. Cool to room temperature and filter with suction to obtain a white powdery solid. The product was washed with petroleum ether, suction filtered, and vacuum-dried to obtain a styrene-maleic anhydride polymer with a yield of 89.0%.

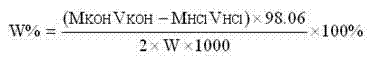

[0029] (2) Determin...

Embodiment 2

[0032] Example 2 Preparation of crude oil pour point depressant SMO-1

[0033] Using the styrene-maleic anhydride polymer and stearyl alcohol synthesized in Example 1 as raw materials, the reaction was carried out at a molar ratio of anhydride to stearyl alcohol of 1:1.1.

[0034] Take 1 g of styrene-maleic anhydride polymer, 1.5293 g of stearyl alcohol, 0.0253 g of p-toluenesulfonic acid as the catalyst, and use toluene as the solvent. Stir the reaction for 12 h at reflux temperature (about 110°C). Distill under reduced pressure to evaporate most of the toluene solvent, precipitate in methanol, filter the precipitate, wash with acetone, and dry in vacuo to obtain a white powder solid, which is crude oil pour point depressant SMO-1, with a yield of 83.0%.

[0035] The infrared spectrum of SMO-1 shows, 2920, 2850 cm -1 is the stretching vibration absorption peak of the alkyl group in the polymer, 1735 cm -1 It is the stretching vibration absorption peak of the ester bond, 7...

Embodiment 3

[0036] Example 3 Preparation of crude oil pour point depressant SMO-2

[0037] Using the styrene-maleic anhydride polymer and octadecylamine synthesized in Example 1 as raw materials, the reaction was carried out at a molar ratio of anhydride to octadecylamine of 1:1.1.

[0038] Take 1 g of styrene-maleic anhydride polymer and 1.5236 g of octadecylamine, use p-toluenesulfonic acid (0.0252 g) as catalyst, use dissolved amount of toluene as solvent, and stir the reaction at reflux temperature (about 110°C) 12 h. Most of the toluene solvent was removed by rotary evaporation, precipitated in methanol, the precipitate was suction filtered, washed with acetone, and dried in vacuo to obtain a white powder solid, which was crude oil pour point depressant SMO-2, with a yield of 85.0%.

[0039] The infrared spectrum of SMO-2 shows: 2919cm -1 , 2850cm -1 is the stretching vibration absorption peak of the alkyl group; 1698 cm -1 There is an absorption peak at , which is the absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com