Pressure-bearing enhanced corrugated plate

A corrugated plate and corrugated technology, which is applied in the design, development and manufacturing of heat transfer elements, can solve the problems of increasing plate thickness, increasing production costs, heat transfer performance and passing performance not reaching the design indicators, and achieving improved pressure bearing The effect of ability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

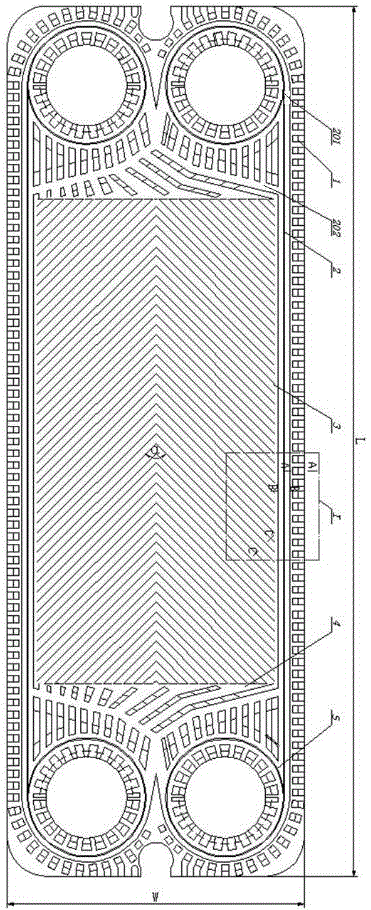

[0025] The corrugated plate is a kind of detachable plate heat exchanger plate. When the whole machine is assembled, the plate is pasted with sealing rubber pad and hung upside down on the beam between the pressing plates, and the plate is pressed by clamping bolts. Tight, the medium enters and exits on the same side of the plate, and the hot and cold medium channels are formed through the sealing rubber pad. The rubber pad is attached in the gasket groove, and the plate is supported by the bubble point to form an inner cavity. Therefore, the structure of the rubber pad sealing groove, the density and support strength of the bubble point, and the rigidity of the overall plate bundle are of great importance to the pressure bearing of the whole machine. important role.

[0026] The present invention and its effects will be further described below in conjunction with the accompanying drawings.

[0027] figure 1 It is a schematic diagram of the plane layout of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com