Auxiliary welding tool fixture of T-shaped connector laser welding robot for aluminum alloy sheets

A welding fixture and robot-assisted technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of unstable gap between skin and stringers, inaccurate auxiliary positioning of weldments, and low accuracy of stringer occupancy, etc. problems, to achieve the effect of simplifying cumbersome installation and operation methods, wide applicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

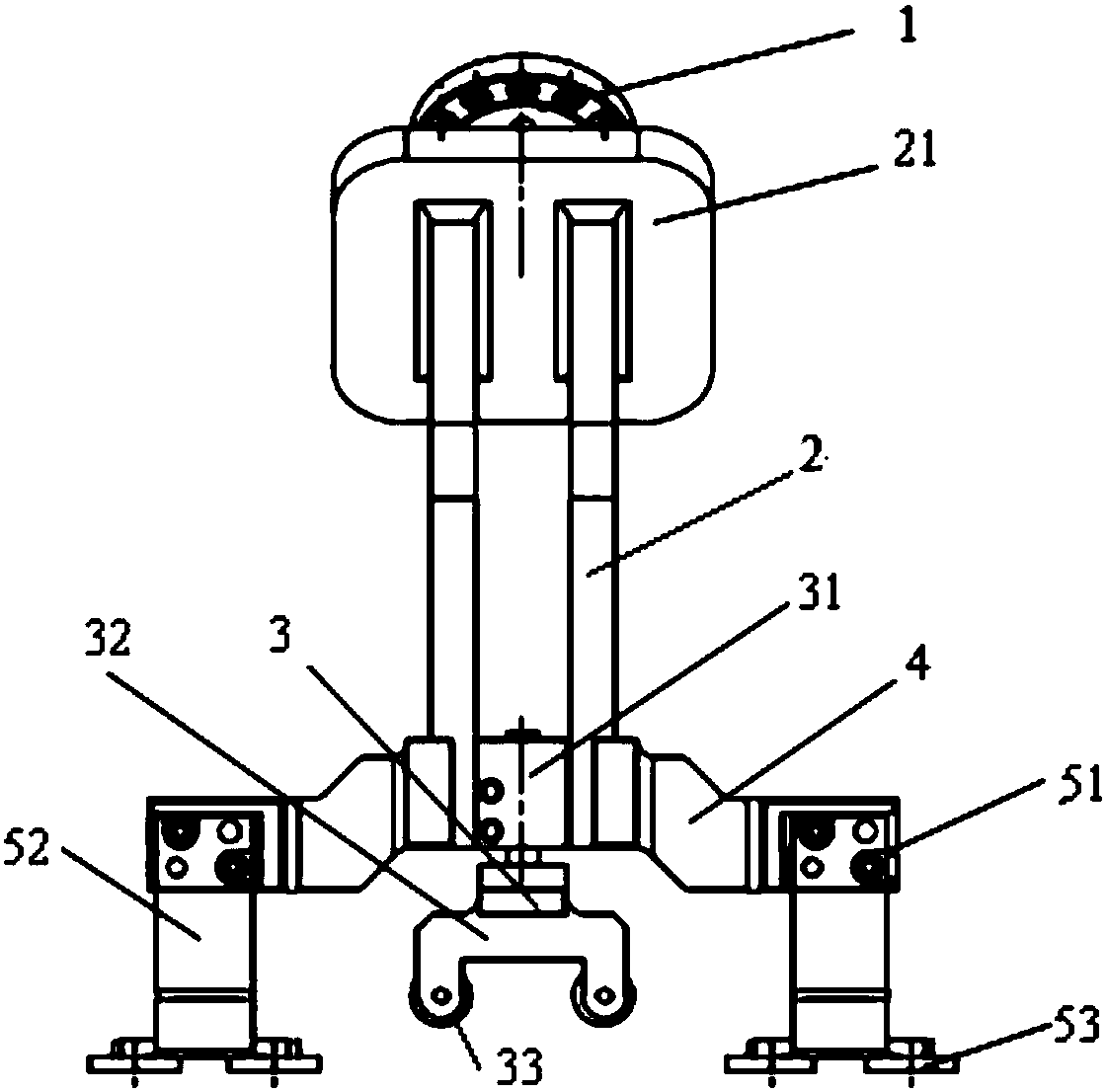

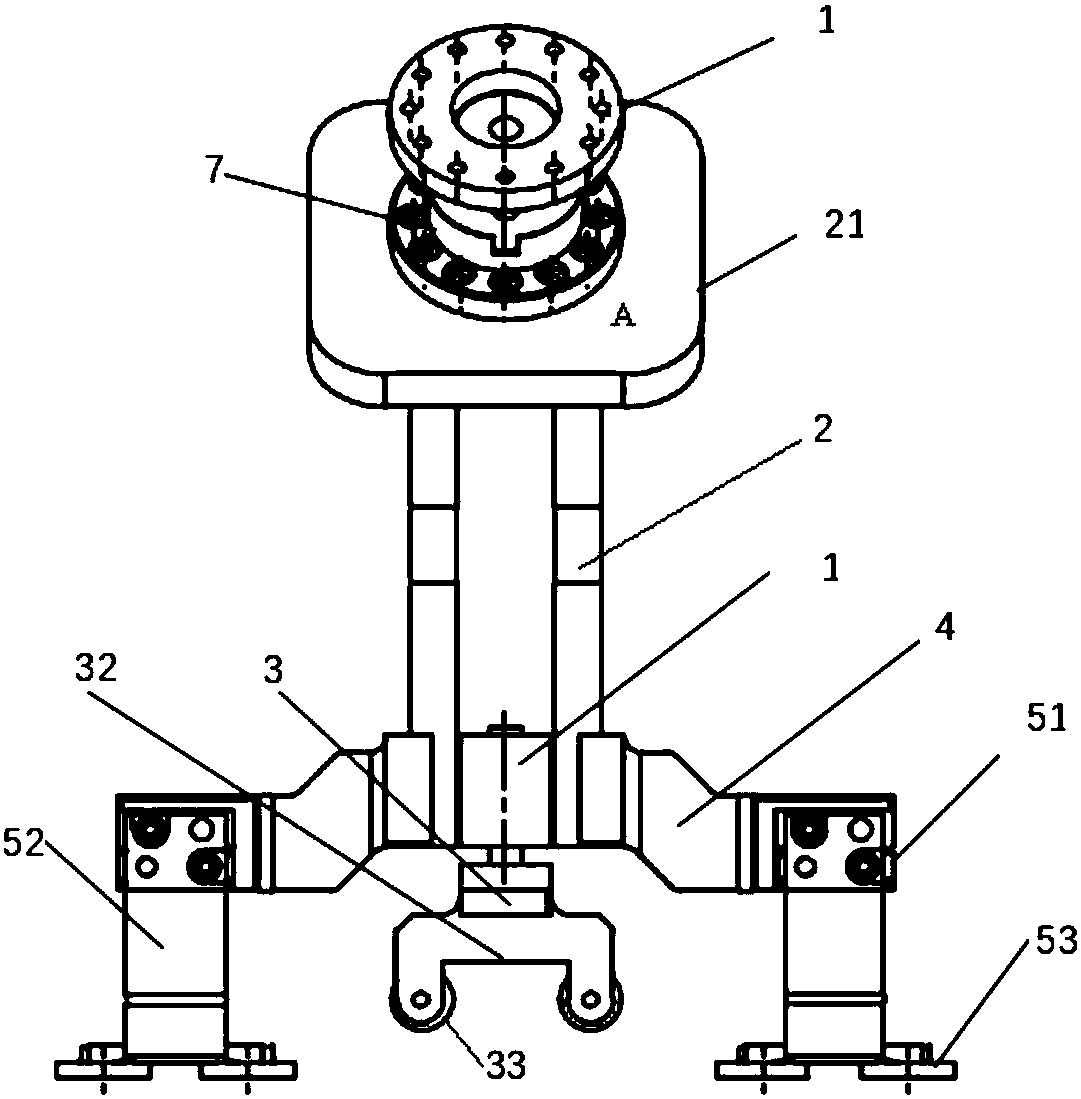

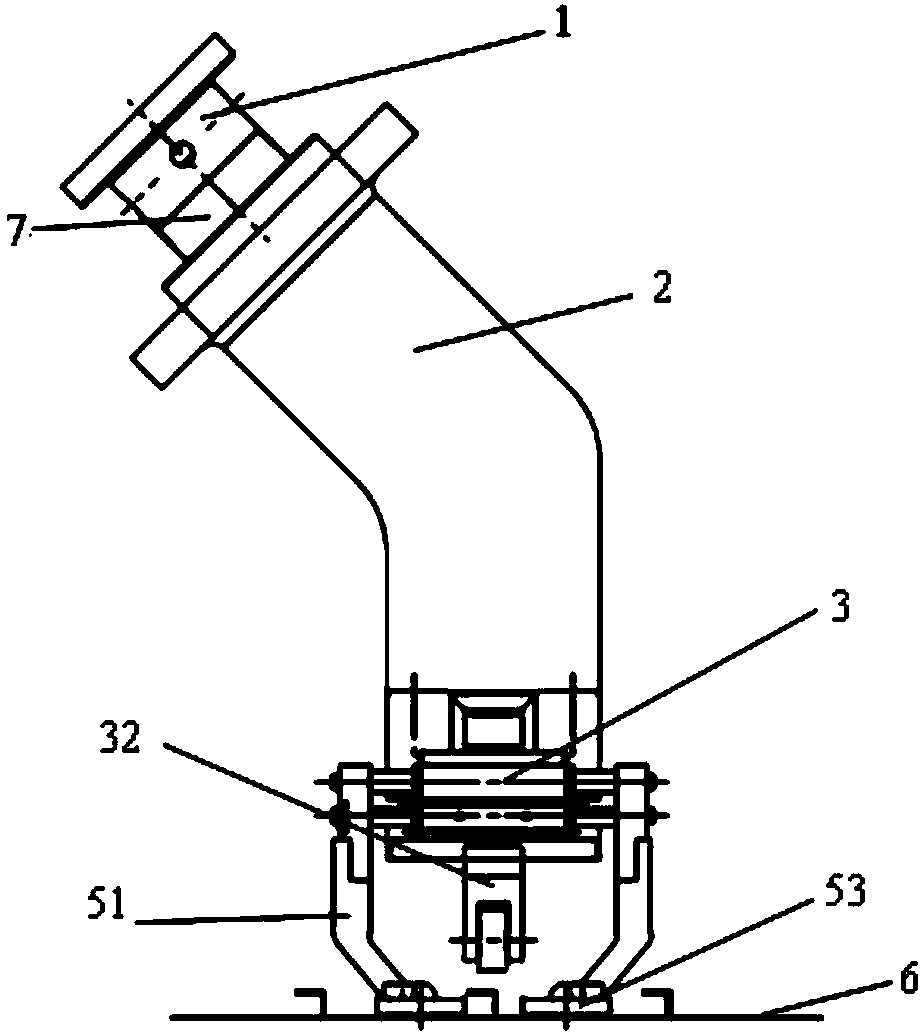

[0036] The auxiliary welding fixture of the present invention is suitable for welding workpieces of aluminum alloy sheet T-shaped joints (such as Figure 14 and Figure 15 ) tooling, such as Figure 15 As shown, there are certain requirements for the spacing and height of the stringers on the skin. The applicable range of the thickness of the aluminum alloy skin is 1.2-2.0mm (H3), and the applicable range of the height of the L-shaped stringers is 18-30mm (H2). In the T-shaped plate structure, the spacing of the T stringers is applicable in the range of 120-150mm (H1). Good results can be obtained when used within the above range.

[0037] The auxiliary welding fixture of the present invention uses a robot arm to carry out a follow-up auxiliary welding process. It is used on a double-beam laser welding wall plate structure and can be used in conjunction with any qualified robot. In order to improve the efficiency of the tooling, a robot transfer mechanism is designed. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com