Railway solid high pier for connecting pre-stressed segment with pre-assembled segment

A prefabricated and prestressed technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of long longitudinal prestressed steel bars and inability to guarantee the prestressing effect, and achieve the effect of convenient transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

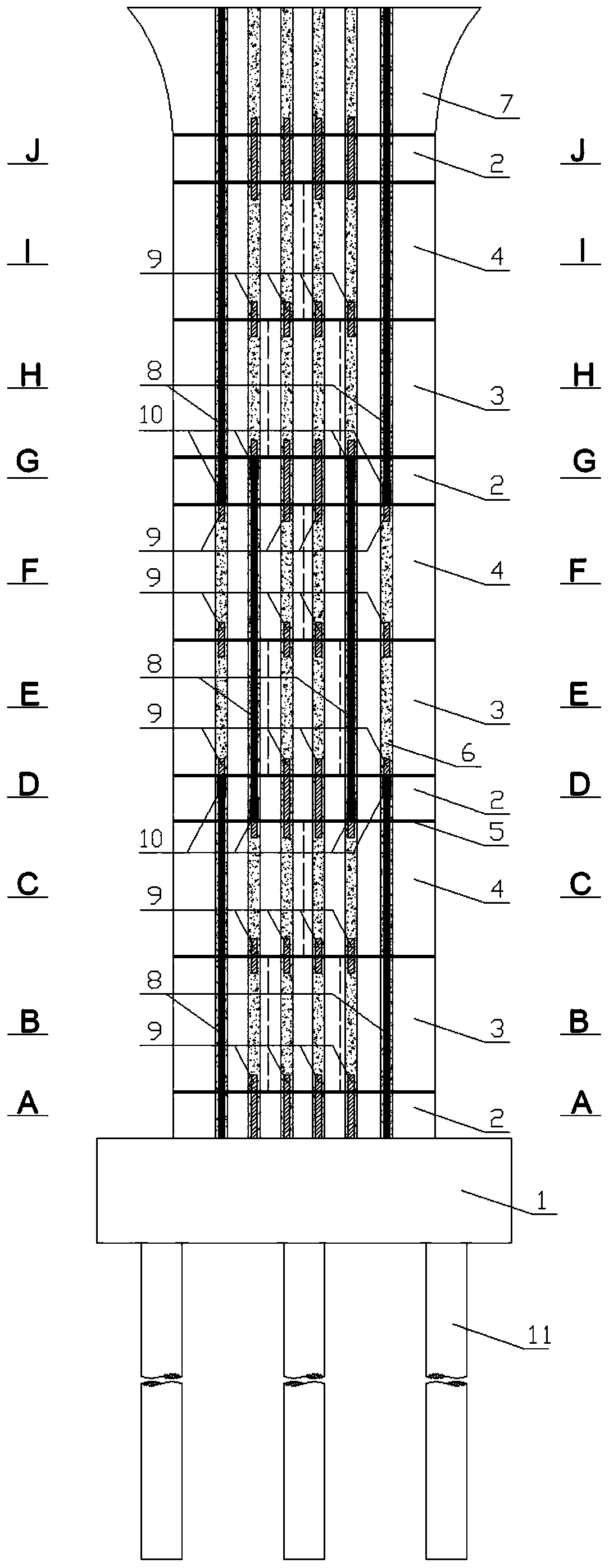

[0029] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0030] The above-mentioned manufacturing method for connecting prefabricated segmental solid high piers based on the concept of segmental tension prestressing includes the following steps:

[0031] 1) Complete the prefabrication work of the pier body sections, caps and other structures in the prefabrication factory. After the prefabrication work is completed, all prefabricated components are transported to the site.

[0032] 2) Clean the groove and boss of the shear key on the module and the upper surface of the module, and apply epoxy adhesive 5 on the segment contact surface and the mortise and tenon part of the module.

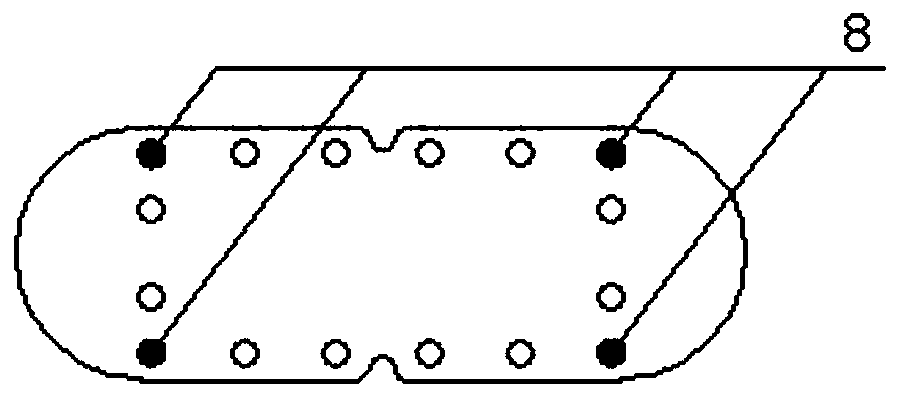

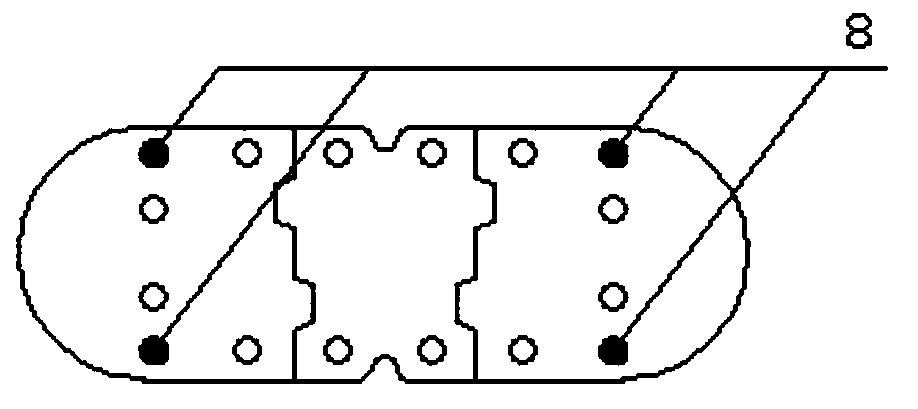

[0033] 3) Place the module as follows Figure 3-4 The second pier segment 3 and the third pier segment 4 are assembled in the assembled manner. then follow figure 1 In the vertical stacking method shown, the first pier segment 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com