Photoresist barrel with temperature monitoring function

A photoresist and functional technology, applied in the field of photoresist barrels with temperature monitoring function, can solve the problems of inaccurate and wasteful judgment methods, and achieve the effect of precise monitoring and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

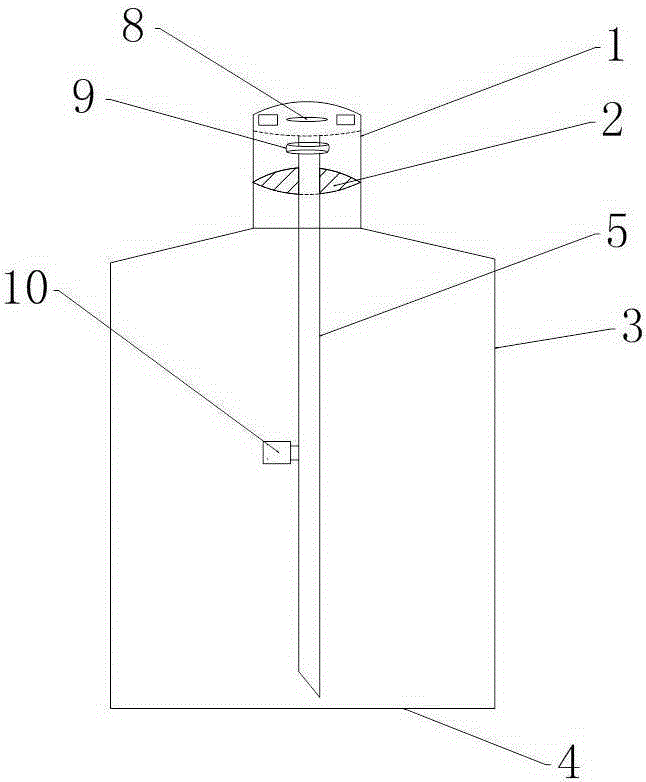

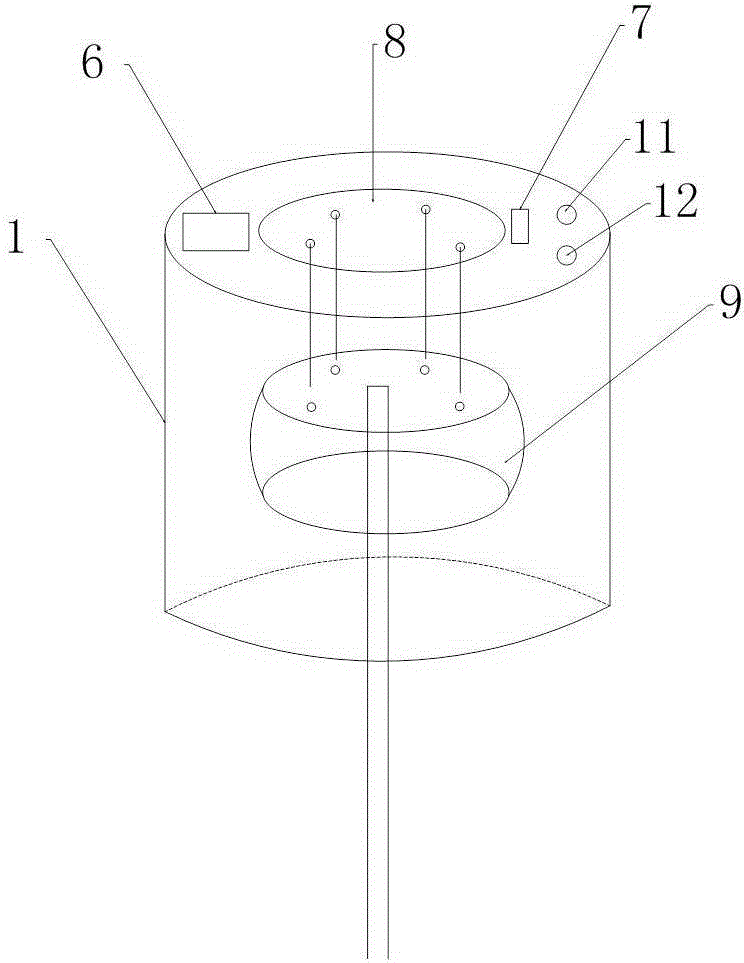

[0018] like figure 1 As shown, a photoresist barrel with a monitoring function in this embodiment includes a barrel cover 1, a barrel mouth 2, a barrel wall 3, a barrel bottom 4, and a drainage tube 5; an LED display screen is arranged on the outside of the barrel cover 1 6 and a buzzer 7, the inside of the bung is provided with a first connector 8, the LED display 6 and the buzzer 7 are connected to the first connector 8 through a line hidden in the bung, and the top of the drainage tube 5 is covered There is a second connector 9; as figure 2 As shown, the first connector of this embodiment is a probe-type plug-in piece, the second connector is a socket slot that matches the probe of the first connector, and the second connector is outside the mouth of the barrel; drainage The middle part of the tube 5 is provided with a temperature sensor 10, and the temperature sensor 10 is connected to the second connector 9 through a circuit arranged on the outer wall of the drainage tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com