Blunt impact indicator methods

An indicator, blunt technology, used in the field of systems for monitoring and indicating high-energy impacts on structures, which can solve the problem of visible indication of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

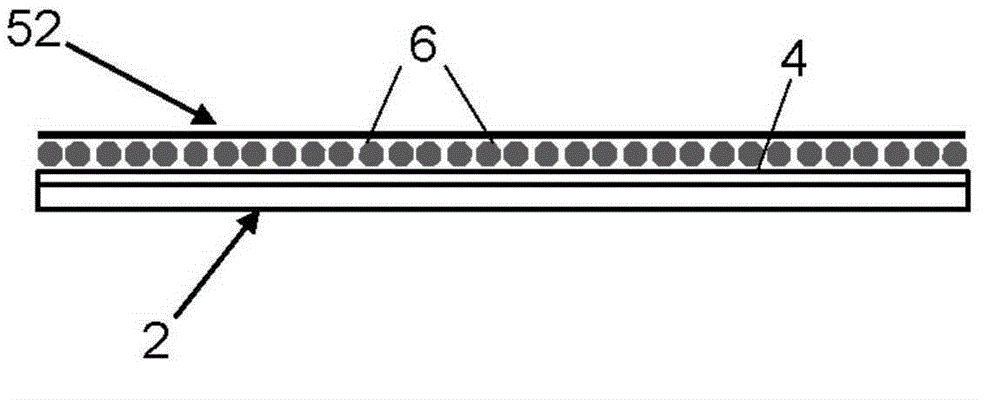

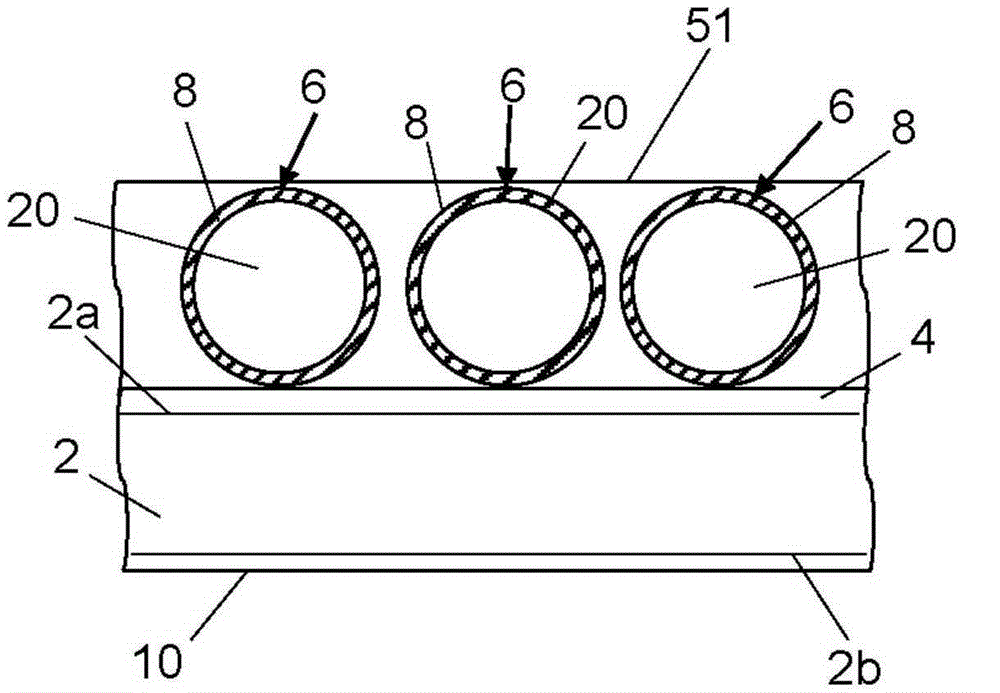

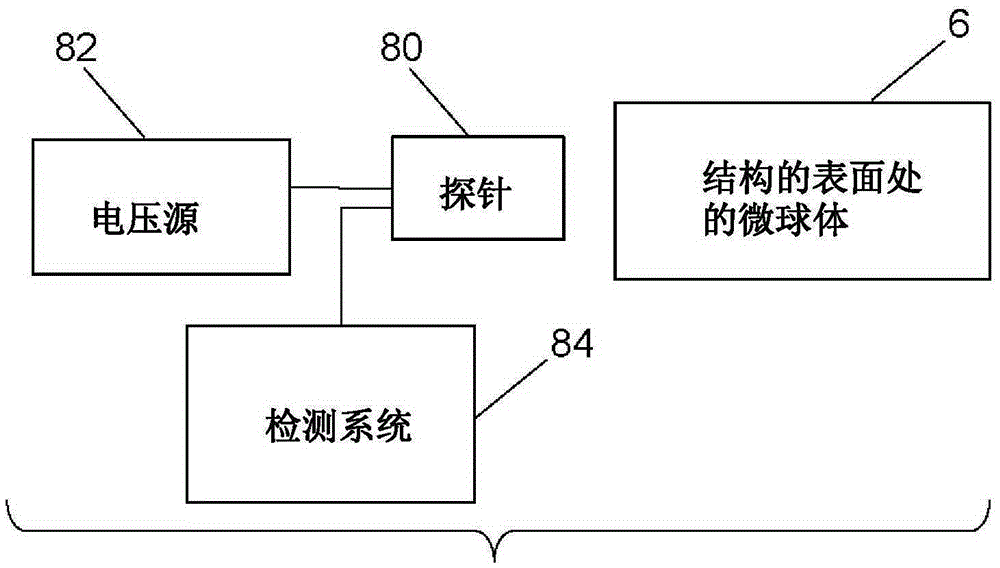

[0101] For purposes of illustration only, various embodiments of blunt impact indicators employing fluid-filled microspheres will now be described in detail. These blunt impact indicators may be applied to the surface of the structure in the form of a substrate (eg, a tape or applique) with an adhesive backing. Microspheres can be attached to a substrate or embedded in a coating applied to the substrate.

[0102] figure 1 A first illustrative embodiment of a blunt impact indicator of the aforementioned type is schematically depicted. The blunt impact indicator comprises a substrate 2 having a plurality of hollow microspheres 6 attached to one surface of the substrate 2 by a layer 4 of adhesive material (hereinafter "adhesive layer 4") and distributed thereon . Optionally, the microspheres 6 are covered by a cover layer 52 .

[0103] The substrate 2 can have different forms. In some cases, substrate 2 may be in the form of a strip comprising thin strips of plastic material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com