Low-voltage overhead parallel bunched insulated wire with prefabricated micro tubules for blown optical cables

A technology of insulated wires and optical cables, applied in the direction of insulated conductors, power cables for overhead applications, insulated cables, etc., can solve the problems of asynchronous design and construction, inflexibility of optical fibers, and many connection points, etc., to improve transmission Quality and reliability, the effect of reducing the number of fiber optic connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

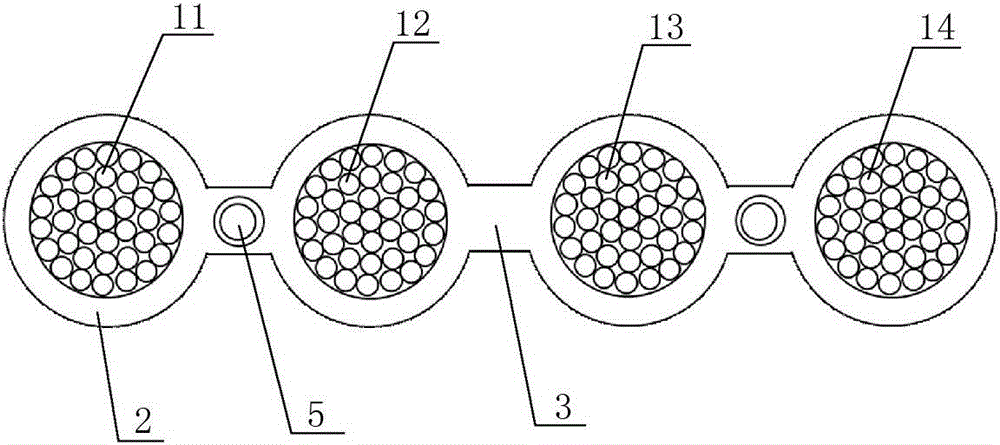

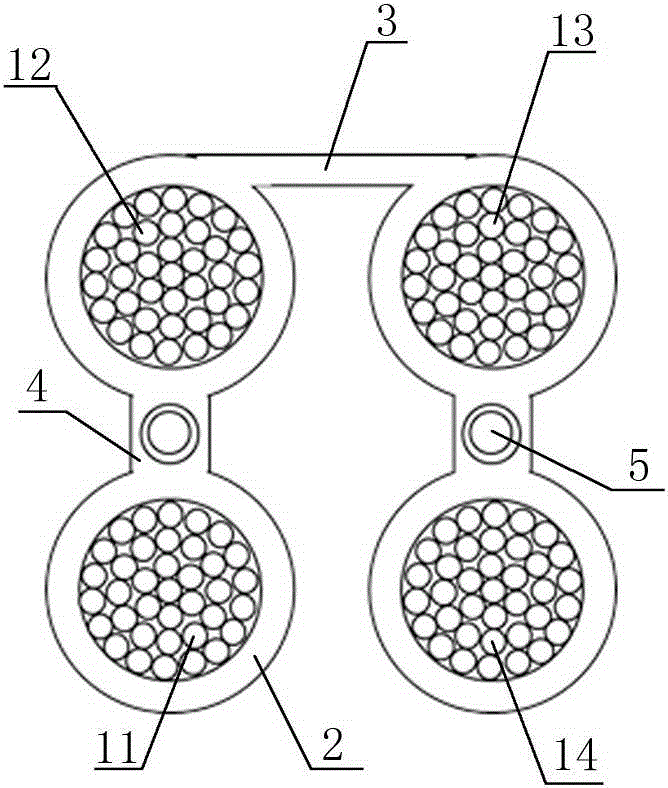

[0027] Such as figure 2 As shown in the figure, a low-voltage aerial parallel collection cable BS1-four-core insulated wire with pre-installed microtubes for air-blown optical cables includes conductive unit A11, conductive unit B12, conductive unit C13 and conductive unit D14 arranged in parallel, and each conductive unit The outside of each is covered with an insulating sheath 2, the vertically parallel conductive unit A11 and the conductive unit B12 are connected by a longitudinal connecting rib 4, and the horizontally parallel conductive unit B12 and the conductive unit C13 are connected by a horizontal connecting rib 3 Connection, the conductive unit C13 and the conductive unit D14 arranged in parallel vertically are connected through the longitudinal connecting rib 4, and the microtube 5 for the air-blowing optical cable is preset in the two longitudinal connecting ribs 4, that is, the air-blowing optical cable is reserved. It can be installed and connected with overhea...

Embodiment 2

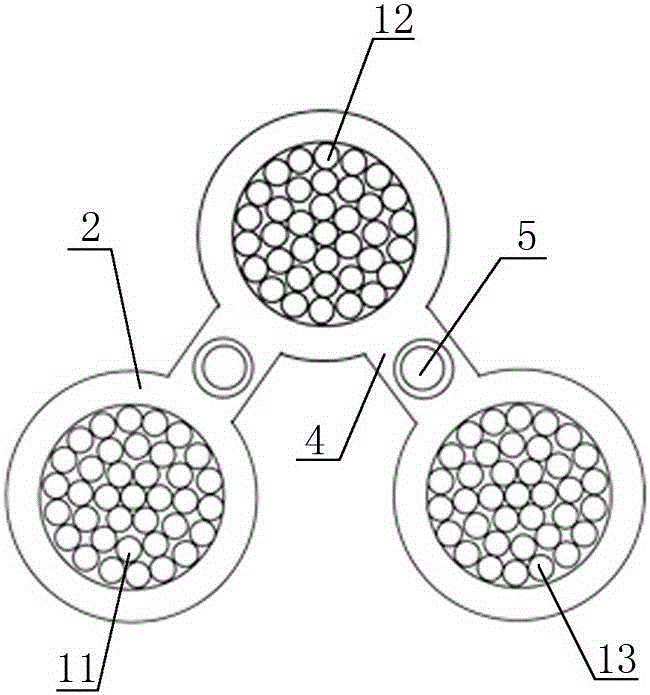

[0030] Such as image 3 As shown, a kind of low-voltage aerial parallel collection cable BS2-three-core insulated wire with pre-installed microtubes for air-blown optical cables, including conductive unit A11, conductive unit B12 and conductive unit C13 arranged in parallel, and the outside of each conductive unit is covered Covered with an insulating sheath 2, the conductive unit B12, the conductive unit A11, and the conductive unit C13 are respectively connected by longitudinal connecting ribs 4, and the two longitudinal connecting ribs 4 are equipped with microtubes 5 for air-blown optical cables, and three of them are conductive The units are triangularly arranged in parallel. This is mainly used in low-voltage power supply networks with 380V three-phase neutral wires not grounded, so only 3 phase wires are required.

[0031] The material, size and other manufacturing requirements of each conductive unit, insulating sheath 2 and microtube 5 for air-blown optical cable are...

Embodiment 3

[0033] Such as Figure 4 As shown, a kind of low-voltage overhead parallel collection cable BS3-two-core insulated wire with microtubes for pre-installed air-blown optical cables, including conductive units A11 and B12 arranged in parallel, and the outside of each conductive unit is covered with an insulating sheath. The sleeve 2, the conductive unit A11 and the conductive unit B12 are connected by a transverse connecting rib 3, and the transverse connecting rib 3 is provided with a micropipe 5 for an air-blown optical cable.

[0034] The material, size and other manufacturing requirements of each conductive unit, insulating sheath 2 and microtube 5 for air-blown optical cable are the same as those in Embodiment 1.

[0035]The low-voltage overhead parallel cable collection insulated wire of the present invention does not change the shape of the overhead parallel cable collection wire, and can be installed with conventional fittings and accessories. Although it includes wires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com