Neodymium iron boron magnet and preparation method

A neodymium iron boron and magnet technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of easy oxidation of heavy rare earth metal compounds, poor oxidation resistance of magnets, reduction of remanence and magnetic energy product, etc. , to achieve the effect of saving heavy rare earth resources, remanence and maximum magnetic energy product stability, and magnetic energy product reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

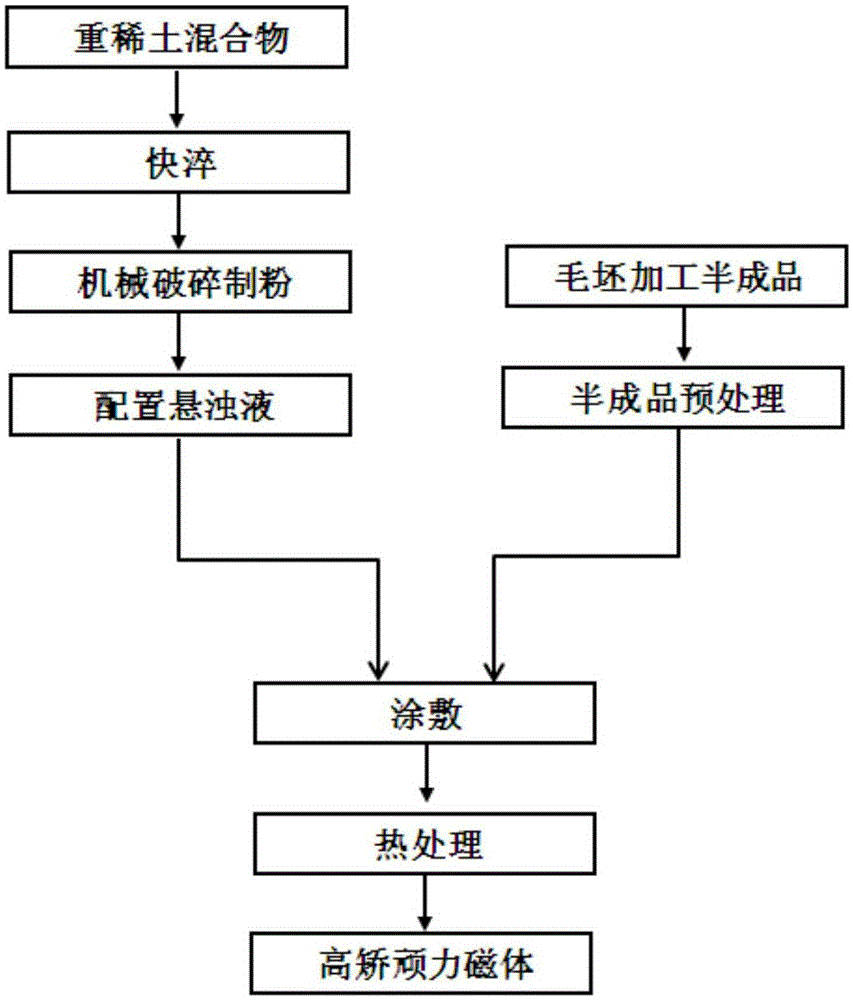

[0030] The present invention also provides a preparation method of an NdFeB magnet, comprising the following steps:

[0031] A) After the rare earth metal is subjected to rapid quenching, the rare earth amorphous belt is obtained, and after crushing, the rare earth amorphous powder is obtained;

[0032] B) mixing the rare earth amorphous powder obtained in the above steps with an organic solvent to obtain a suspension;

[0033] C) coating the suspension obtained in the above steps on the surface of the NdFeB blank to obtain a semi-finished product;

[0034] D) After heat-treating the semi-finished product obtained in the above steps, an NdFeB magnet is obtained.

[0035] In the present invention, firstly, the rare earth metal is rapidly quenched to obtain rare earth amorphous strips, and then crushed to obtain rare earth amorphous powder; the rare earth amorphous strips are preferably heavy rare earth amorphous strips. The method of rapid quenching in the present invention i...

Example Embodiment

[0046] Example 1

[0047] The rare earth Dy is put into a high-vacuum quick-quenching equipment, and the line speed of the cold roll is adjusted to 40 m / s by vacuuming. After quick-quenching, a rare-earth amorphous strip is obtained.

[0048] The rare earth amorphous ribbons obtained in the above steps are crushed in a ball mill to obtain rare earth amorphous Dy powder with an average particle size of about 2 μm, and the crushed powder is added to ethanol to form a suspension.

[0049] Process the 35SH NdFeB blank into a semi-finished product of 18*9.75*2.1 (2.1 is the orientation direction), process the semi-finished product, degrease and other pretreatments to make the surface clean and smooth; then put the pretreated semi-finished product into the suspension Soak the coating in the solution, so that the surface is evenly coated with a layer of amorphous Dy film, and then dry; then place the semi-finished product in a sintered graphite box, put the graphite box with the prod...

Example Embodiment

[0057] Example 2

[0058] Put the rare earth Dy and Tb into the high vacuum quick quenching equipment according to the mass ratio of 1:1, vacuumize and adjust the line speed of the cold roll to 50m / s, and obtain the rare earth amorphous belt after quick quenching.

[0059] The rare earth amorphous ribbon obtained in the above steps is crushed in a ball mill to obtain rare earth amorphous DyTb powder with an average particle size of about 1.8 μm, and the crushed powder is added to ethanol to form a suspension.

[0060] Process the 42SH NdFeB blank into a semi-finished product of 45*21*1.9 (1.9 is the orientation direction), process the semi-finished product, degrease and other pretreatments to make the surface clean and smooth; then put the pretreated semi-finished product into the suspension Soak the coating in the liquid to make the surface evenly coated with a layer of amorphous DyTb film, and then dry it; then place the semi-finished product in a sintered graphite box, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com