Protection disc for hammer crusher

A hammer crusher and hammer hole technology, which is used in grain processing and other directions, can solve the problems of easy loosening of the bolt connection between the hammer shaft and the guard plate, and wear of internal parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

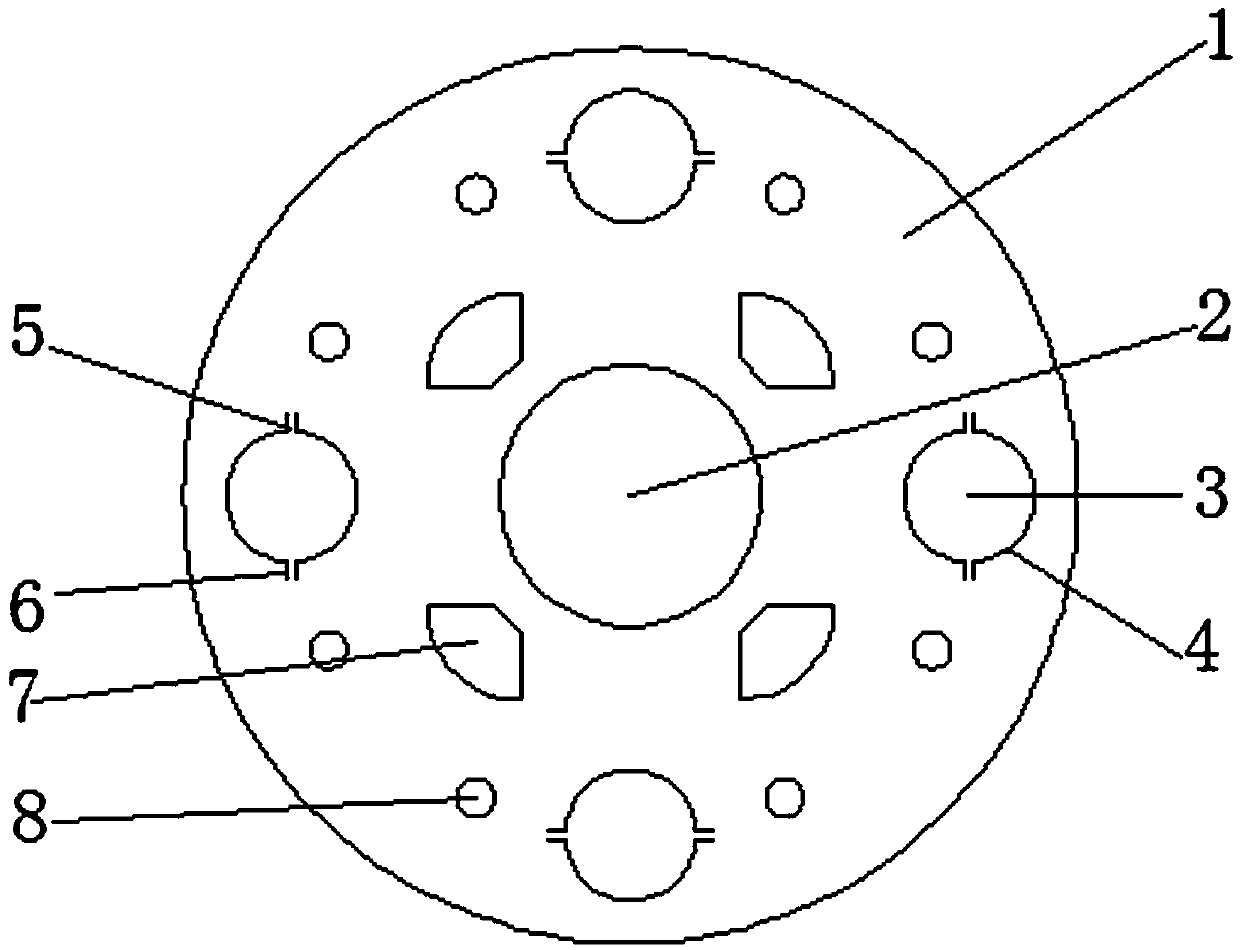

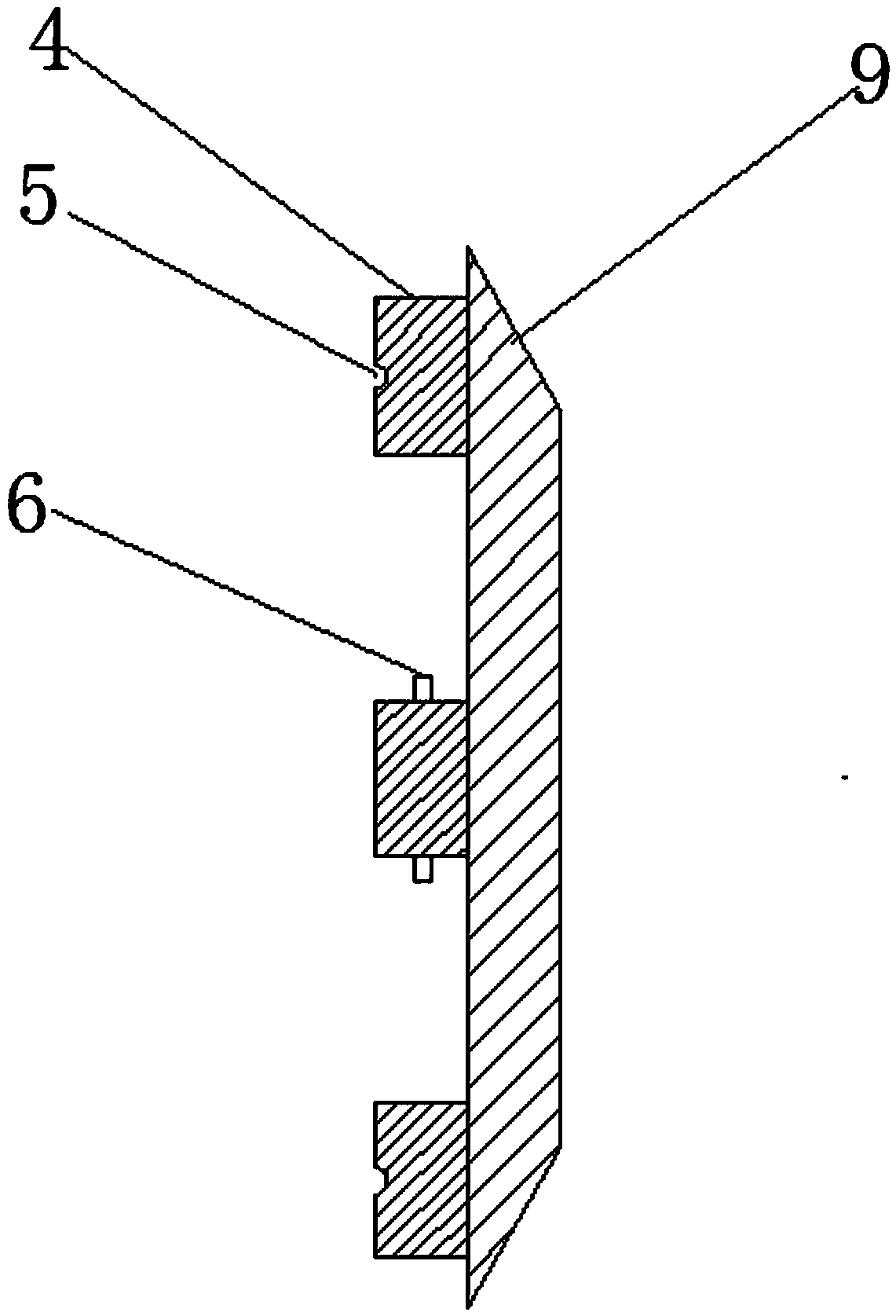

[0015] The reference signs in the accompanying drawings of the specification include: the plate body 1, the round hole 2, the hammer hole 3, the snap ring 4, the clip groove 5, the welding groove 6, the weight reducing hole 7, the weight adjustment hole 8, and the inclined surface 9.

[0016] Such as figure 1 and figure 2 As shown, a hammer crusher guard plate includes a guard plate body 1, a round hole 2 is provided at the center of the guard plate body 1 for the main shaft to pass through, and a number of hammer holes 3 are uniformly arranged on the guard plate body 1 around the center of the circle. The edge of the hammer hole 3 extends axially along the hammer hole 3 with a snap ring 4, and the snap ring 4 is provided with two snap grooves 5. There is a welding groove 6 extending outward. The outer circular surface of the guard plate body 1 is an inclined surface 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com