Grinding and finishing process of integral peach-shaped groove of bearing ring

A technology for bearing rings and channels, which is applied in the field of peach-shaped channel grinding and lapping technology, can solve the problems of integral peach-shaped channel grinding, etc., and achieve the goal of improving accuracy, improving surface quality, and improving waviness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

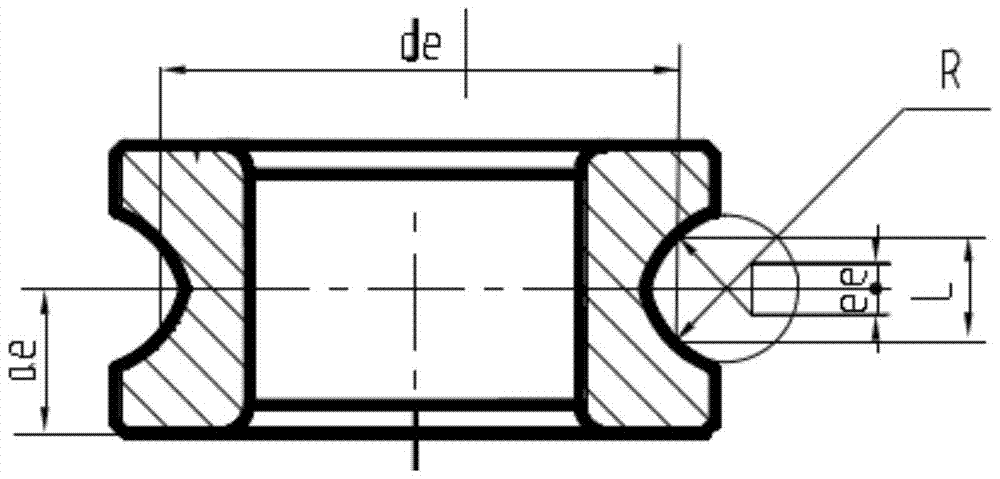

[0033] Specific implementation mode 1: In this implementation mode, the overall peach-shaped channel grinding and lapping process of the bearing ring is carried out according to the following steps:

[0034] 1. Use high-precision CNC cylindrical grinding equipment to grind the groove of the bearing ring into a peach shape;

[0035] 2. Overall peach-shaped channel shape detection:

[0036] ①Detect the radius of curvature R of the channel: tilt the circular curvature sphere 45° along the center line, remove about 1 / 3 of the spherical surface of the circular curvature sphere, and then use the curvature sphere to detect the radius of curvature R of the channel by coloring;

[0037] ② Use a profiler to detect the eccentricity e of the channel position;

[0038] The workpieces whose channel curvature radius R or channel position eccentricity e do not meet the requirements are ground again by readjusting the parameters with high-precision CNC cylindrical grinding equipment; the chan...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the width of the whetstone in Step ① of Step 3 is 0.8-1.2 mm wider than half of the overall peach-shaped channel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the model of the oilstone in step three is SG / SCW400#. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com