Secondary refining method of 10 to 30 tons bottom breakout ladle

A technology of ladle and ladle furnace, which is applied in the field of 10-30 ton bottom leakage ladle refining outside the furnace, can solve the problems of inability to open the ladle, deformation of the plug rod, insufficient refining time, etc. The effect of liquid quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

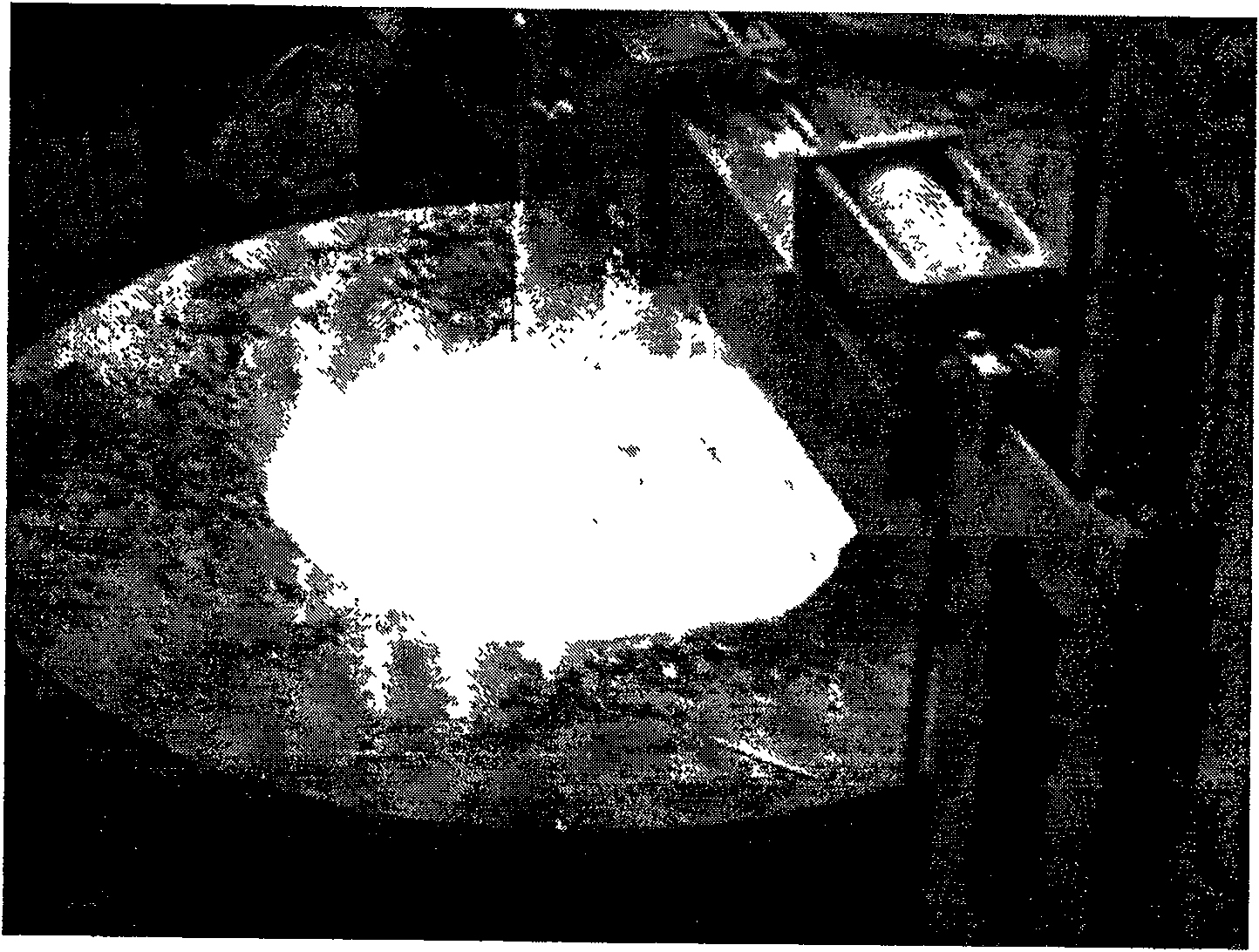

[0038] The material of this embodiment is No. 45 steel, the weight of molten metal is 10 tons, and the refining time is 30 minutes.

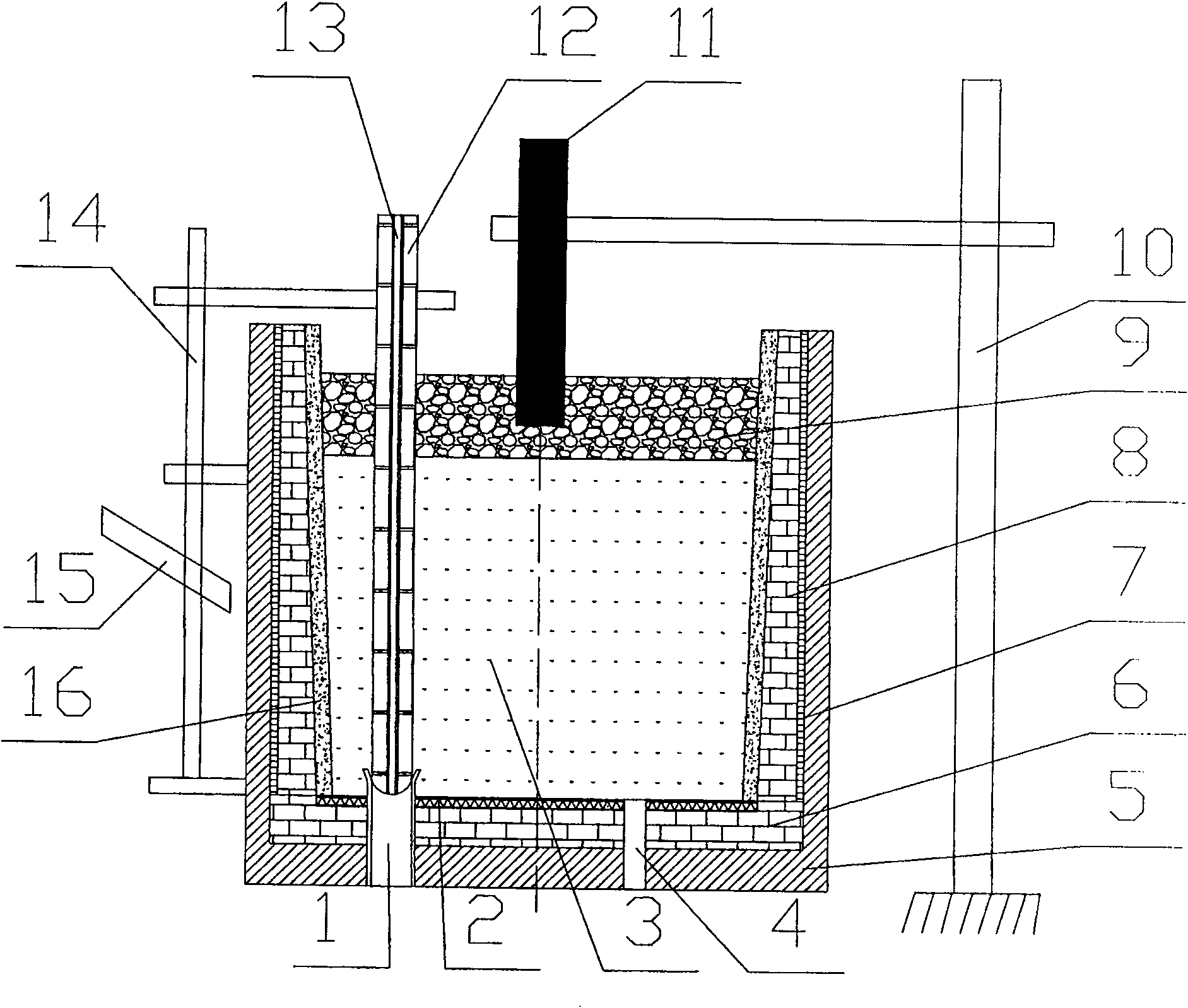

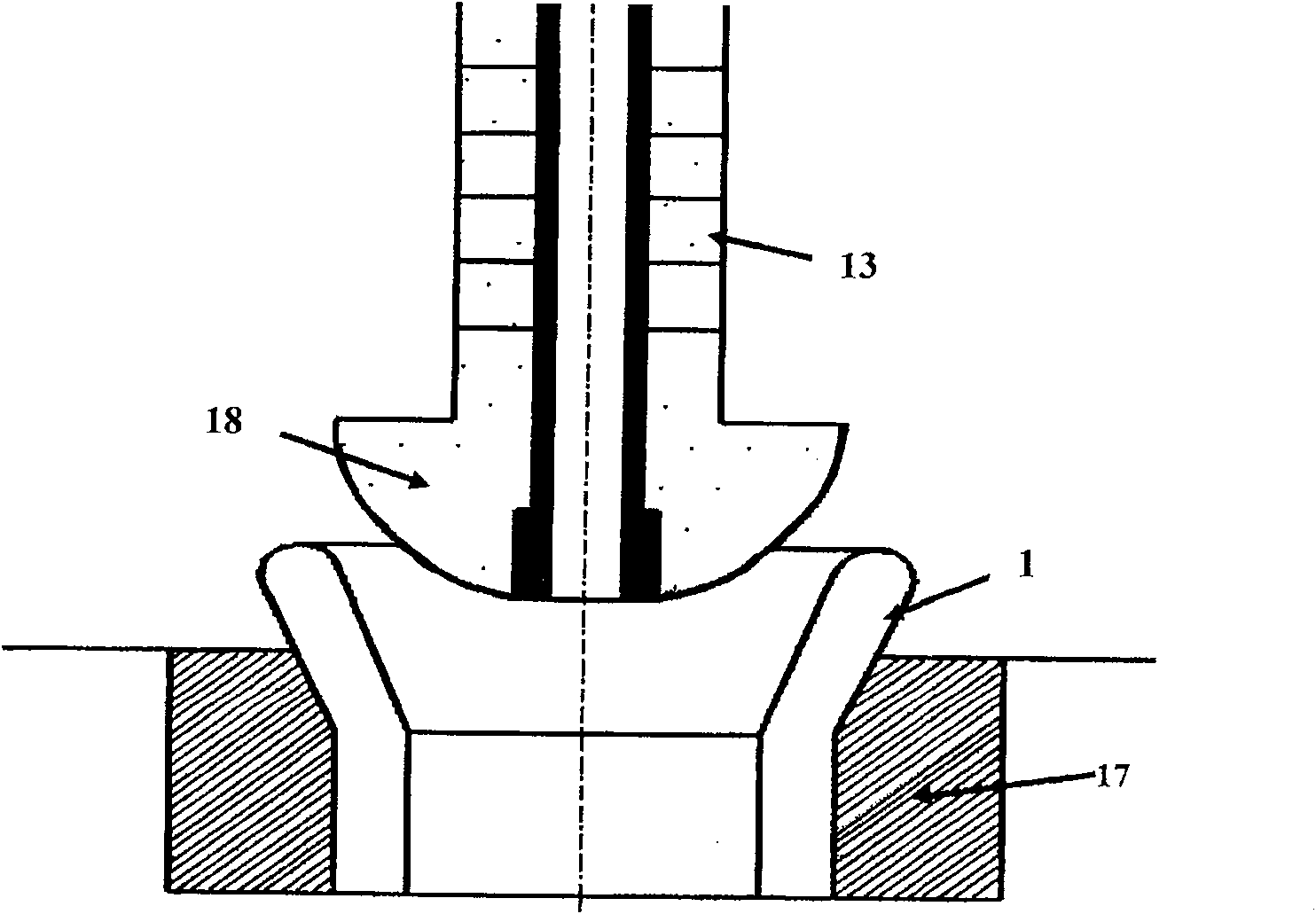

[0039] The implementation of the present invention is as follows: mainly adopt early electroslag protection technology, electroslag heating technology, long-time argon blowing refining technology, technology of preventing plug rod sticking, technology of preventing plug rod deformation, technology of avoiding entrainment, inclusion technology and furnace lining protection technology Wait. The specific process is as follows:

[0040] 1. Early electroslag protection, place electroslag with a thickness of 200mm at the bottom of the ladle before the molten steel is released from the furnace. The main components of electroslag are: CaF2 70wt%, Al 2 o 3 30 wt%. The graphite electrode is placed in the protective electroslag on the upper part of the molten metal, at 2 / 3 of the thickness of the electroslag, the electroslag heating time is 30 minutes,...

Embodiment 2

[0045] The material of this embodiment is high manganese steel, the weight of molten metal is 15 tons, and the refining time is 35 minutes.

[0046] The implementation of the present invention is as follows: mainly adopt early electroslag protection technology, electroslag heating technology, long-time argon blowing refining technology, technology of preventing plug rod sticking, technology of preventing plug rod deformation, technology of avoiding entrainment, inclusion technology and furnace lining protection technology Wait. The specific process is as follows:

[0047] 1. Early electroslag protection, place electroslag with a thickness of 300mm on the bottom of the ladle before the molten steel is released from the furnace. The main component of electroslag is: CaF 2 75wt%, Al 2 o 3 25 wt%. The graphite electrode is placed in the protective electroslag on the upper part of the molten metal, at 2 / 3 of the thickness of the electroslag, the electroslag heating time is 35...

Embodiment 3

[0052] The material of this embodiment is 35CrMo steel, the weight of molten metal is 25 tons, and the refining time is 40 minutes.

[0053] The implementation of the present invention is as follows: mainly adopt early electroslag protection technology, electroslag heating technology, long-time argon blowing refining technology, technology of preventing plug sticking, technology of preventing plug rod deformation, technology of avoiding gas entrainment, inclusion technology and furnace lining protection technology Wait. The specific process is as follows:

[0054] 1. Early electroslag protection, place electroslag with a thickness of 400mm at the bottom of the ladle before the molten steel is released from the furnace. The main component of electroslag is: CaF 2 80wt%, Al 2 o 3 20 wt%. The graphite electrode is placed in the protective electroslag on the upper part of the molten metal, which is 3 / 4 of the thickness of the electroslag. The electroslag heating time is 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com