Method for implementing decorative element including apperance layer with wood material tape

An implementation method and wood material technology are applied in the field of implementing decorative pieces including an appearance layer with wood material strips, which can solve problems such as bulging, damage, and deformation of decorative pieces, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the description, the term "external" is defined towards the exterior of the trim, i.e. towards the visible side of the trim, and the term "interior" is defined towards the rear of the trim, i.e. when the trim is installed in its surroundings , toward the invisible side of the trim.

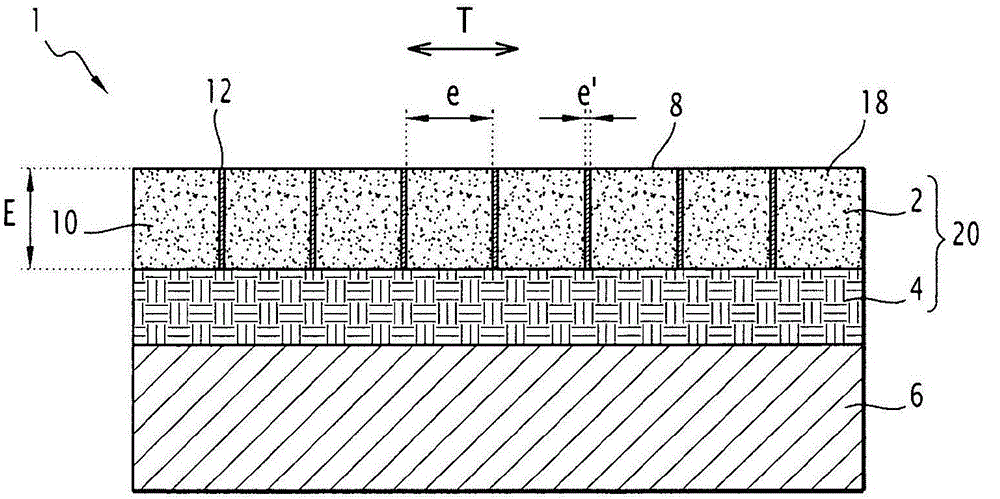

[0039] Referring to the accompanying drawings, a decorative part 1 ( image 3 ).

[0040] The appearance layer 2 has an outer face 8 which forms the outer surface of the trim part 1 . Such as Figure 4 As shown, the outer face 8 has a complex three-dimensional shape. According to one embodiment, the outer face 8 forms a non-deployable surface.

[0041] Furthermore, in order to give the trim part a special appearance, the outer face 8 of the trim part has a "wooden" appearance, ie it has the appearance of a wooden layer.

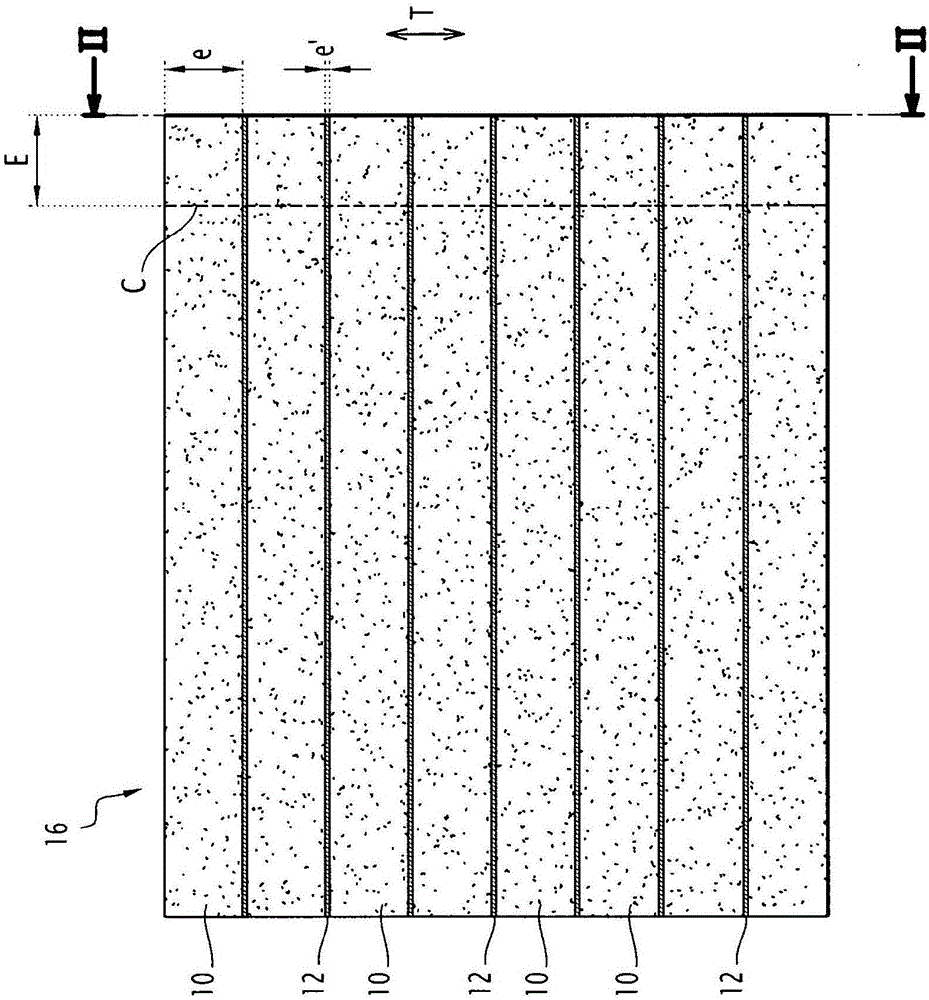

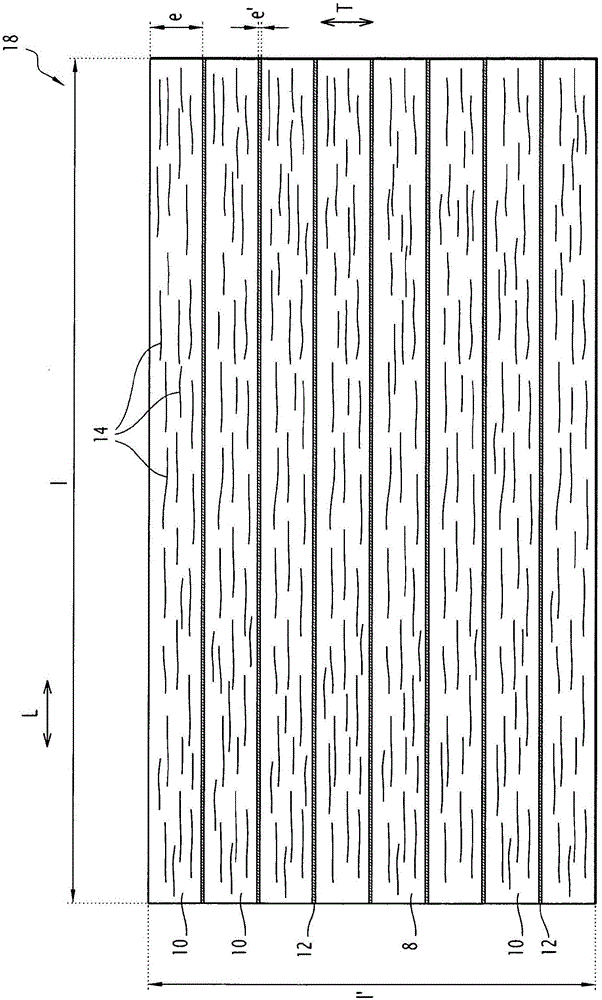

[0042] now refer to figure 1 and 2 Now, the implementation method of the appearance layer 2 will be described. This implementation method can make the outer surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com