Automobile shell with self-healing function

A technology for car shells and doors, which is applied to vehicle parts, upper structures, bumpers, etc., can solve problems such as affecting the appearance, delaying the use of the car, increasing costs, etc., and achieves the effect of solving the problem of shell depressions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

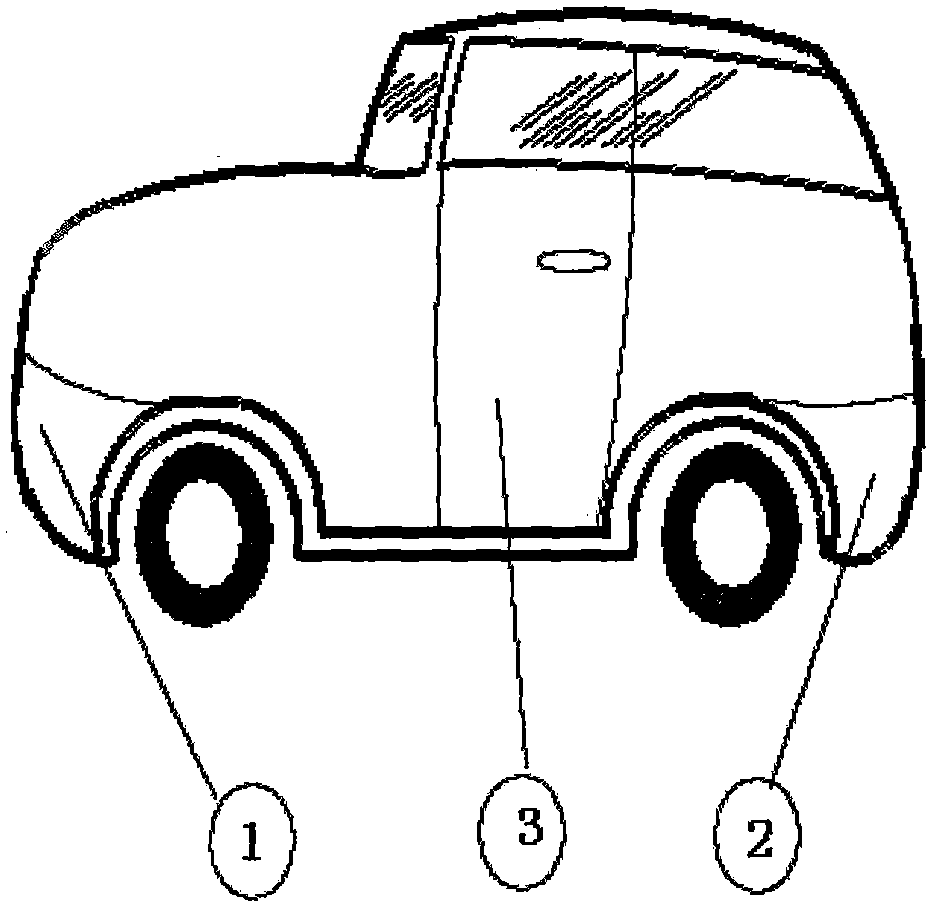

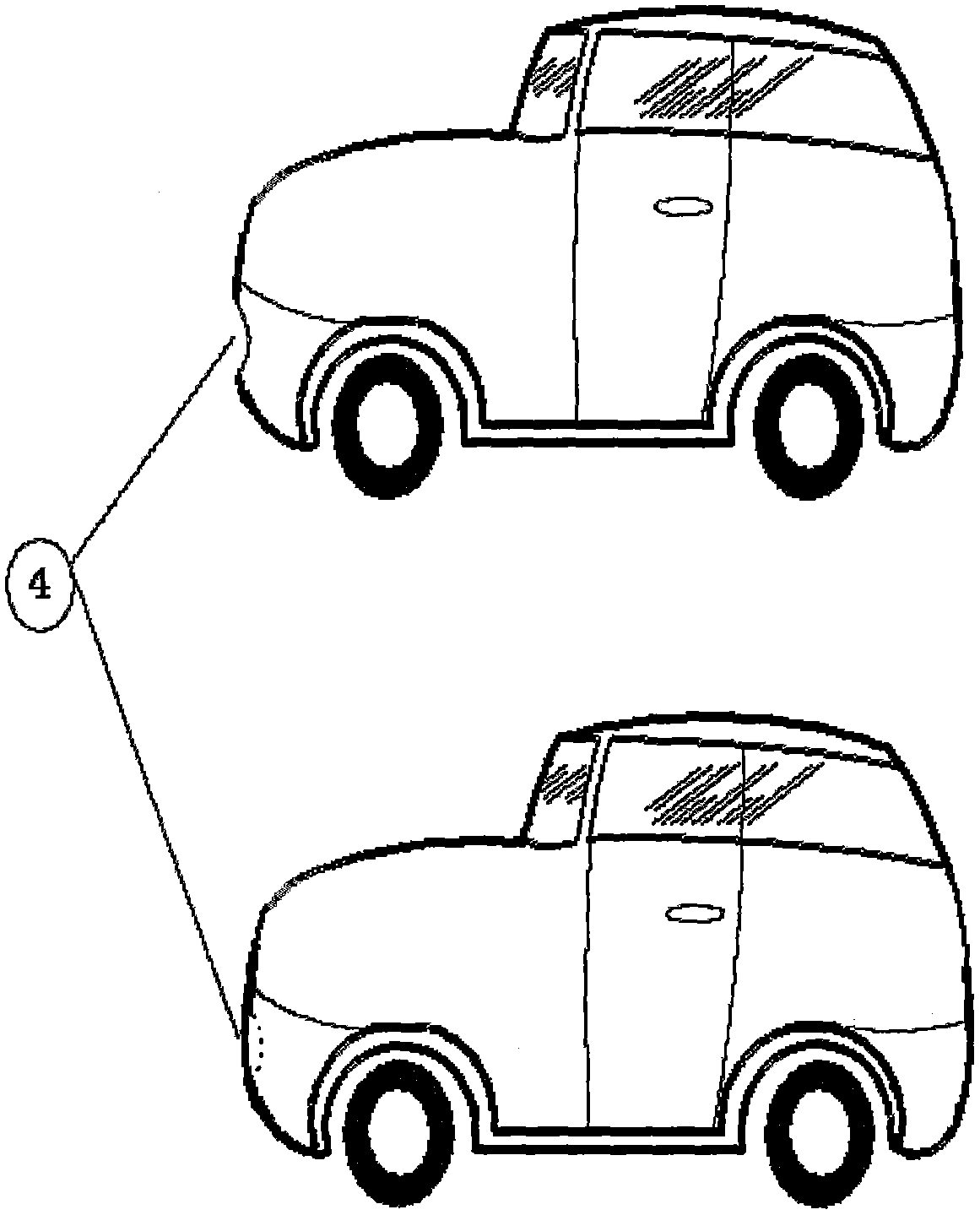

[0008] A memory alloy plate mainly composed of nickel and titanium is used to manufacture a car shell with self-healing function, which is composed of a front bumper (1), a rear bumper (2) and a car door (3). Install the front bumper (1), rear bumper (2) and car door (3) on the corresponding positions of the car body. When the car shell with the self-healing function is scratched and dented, after pouring hot water on the sunken part (4) of the car shell, the sunken part (4) of the shell disappears. If the surface paint still falls off, use the same color of portable car paint to cover it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com