A material tray for drying fireworks bright beads

A material tray and bright bead technology, which is applied in the direction of dryers, granular material drying, drying chambers/containers, etc., can solve the problems of uneven drying rate, hardening and crusting of material surface, affecting the discharge effect, etc., and achieve good ventilation and drying Effect, no dead angle of air flow, smooth flow of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

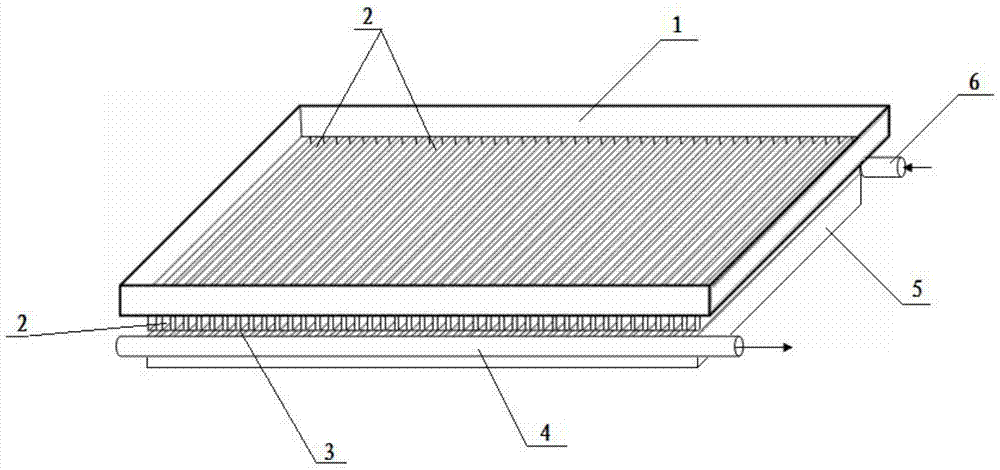

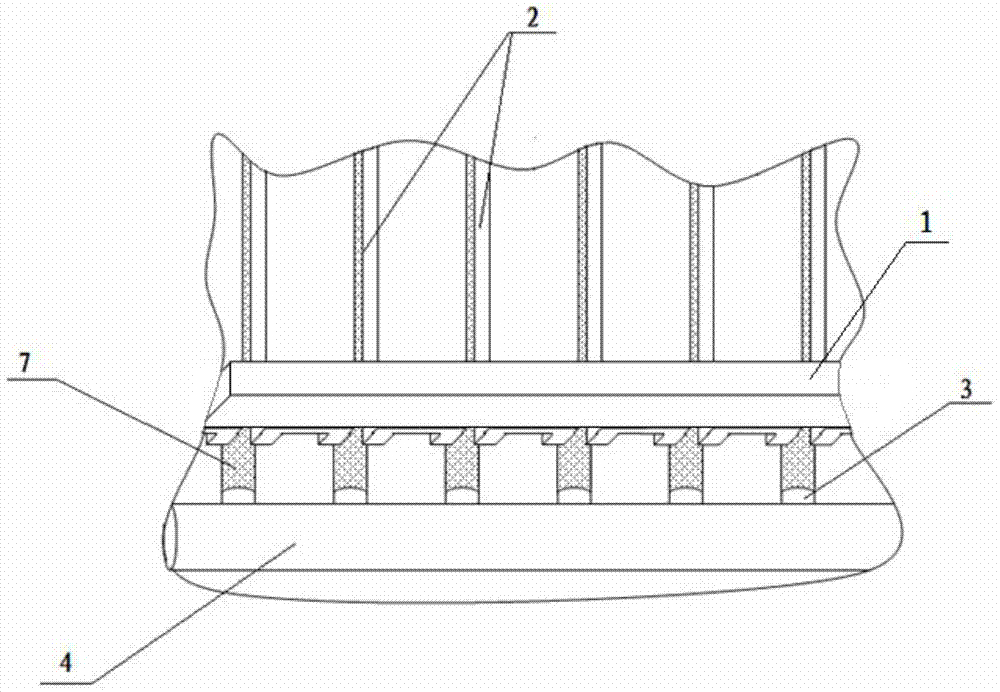

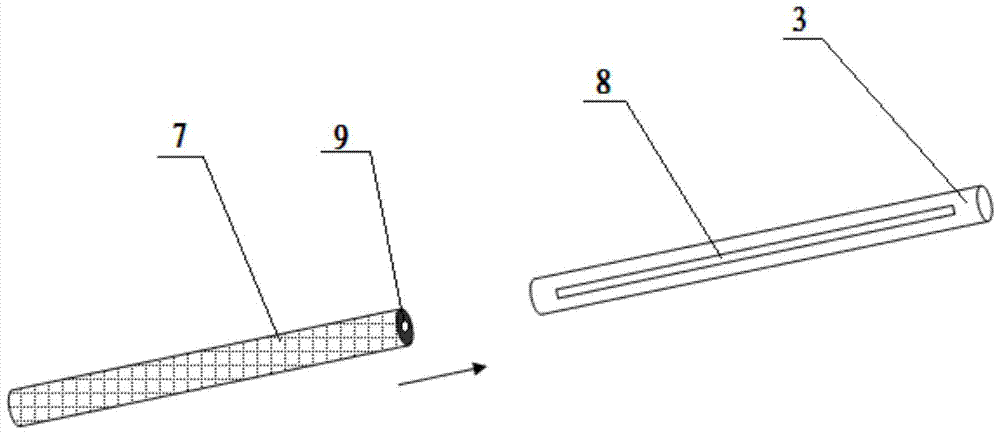

[0012] Referring to the accompanying drawings, reflecting a specific structure of the present invention, the material tray used for drying fireworks bright beads includes a disc body 1, and a number of gaps 2 are evenly distributed on the bottom of the disc body 1, and the width of the gaps 2 is smaller than that of the fireworks bright beads. The particle size of the beads; a buffer rod 3 is correspondingly arranged under each gap 2, and the dust collection box 5 is located below the buffer rod 3; the side of the interlayer between the disc body 1 and the dust collection box 5 is a four-sided ventilation structure. The material tray is provided with a grounding device (not shown in the figure). The buffer rod 3 is provided with a hollow inner cavity, and at least one ventilation gap 8 is provided on the side of the inner cavity. When drying, the inner cavity is connected to the vacuum system through a pipeline and a switching valve; when the material tray is cleaned after dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com