Crane slewing system

A slewing system and crane technology, applied in cranes and other directions, can solve the problems of inconvenient design and processing, different heights, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

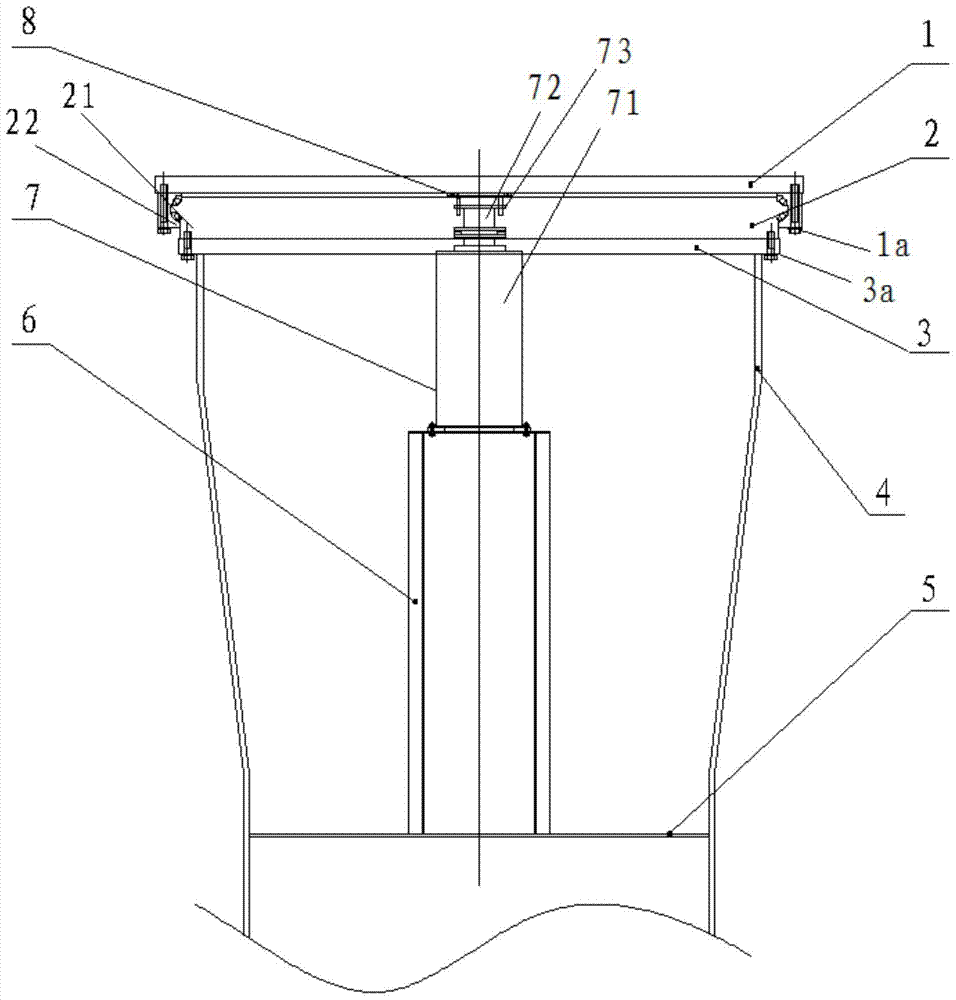

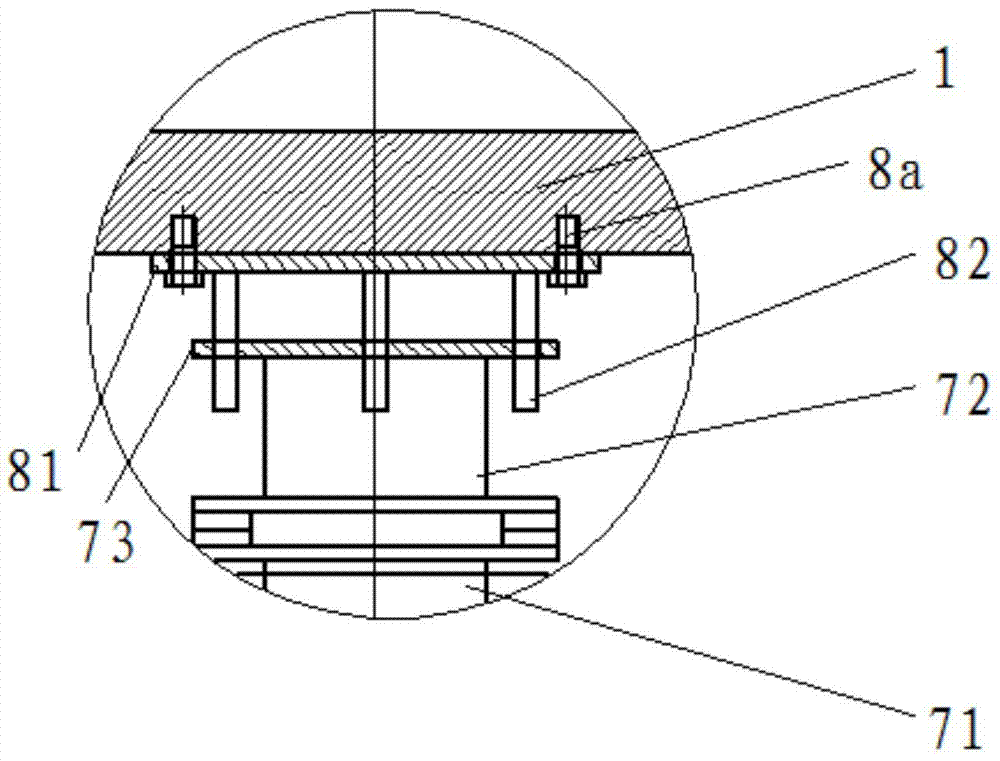

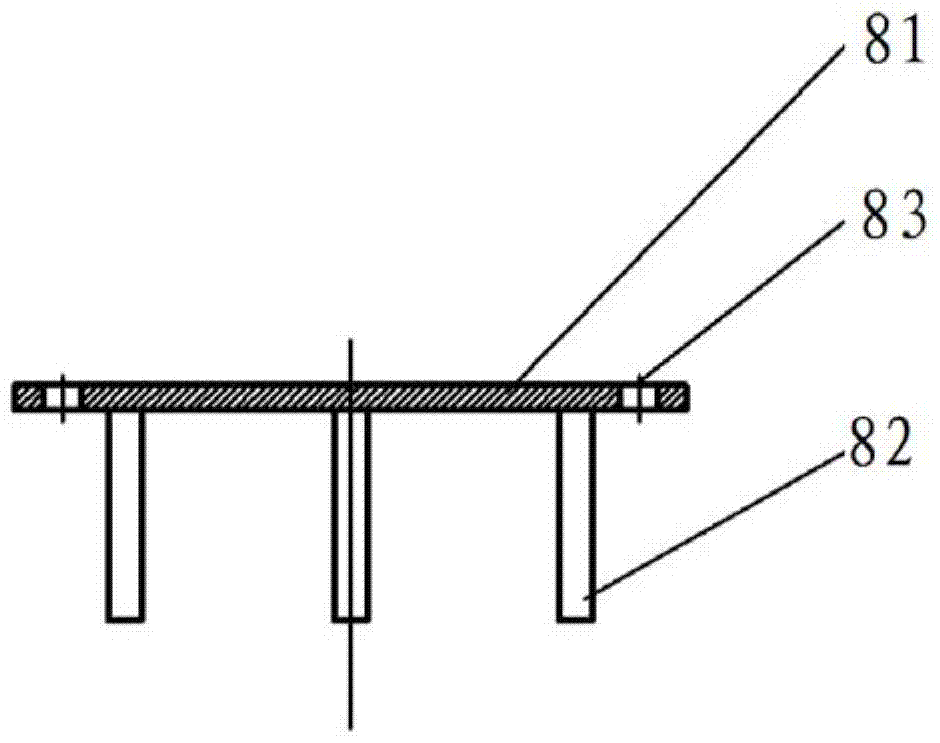

[0024] figure 1 It is a schematic structural diagram of a crane slewing system provided by an embodiment of the present invention, see figure 1 , the system includes: tower base plate 1, slewing bearing 2, base column flange 3, base column 4, base column inner platform 5, slip ring box support 6, slip ring box 7 and upper guide rod 8, slip ring box 7 includes a lower stator 71 and an upper rotor 72 rotatably arranged on the lower stator 71 , and the slewing bearing 2 includes an inner ring 21 and an outer ring 22 rotatable around the inner ring 21 .

[0025] One end of the base column 4 is used to be installed on the platform (such as the hull), the base column inner platform 5 is arranged inside the base column 4, the slip ring box b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap