Y-shaped stop-check valve

A technology of check valve and valve body, applied in the direction of lift valve, valve detail, control valve, etc., can solve the problems of reducing the flow channel area at the outlet, valve sealing and poor operation, and the influence of valve Cv value, etc., to save materials , Disassembly and maintenance are convenient and fast, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

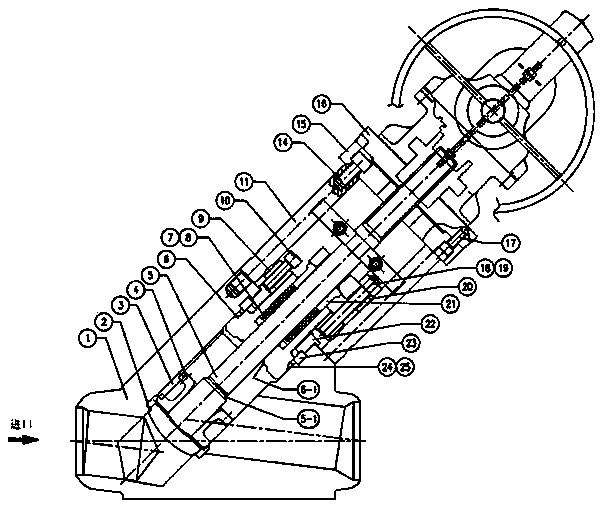

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, a Y-shaped cut-off check valve according to the present invention includes a valve body 1, the valve body 1 is provided with a control end, an inlet end and an outlet end, and the inner cavity of the valve body 1 is provided with a valve seat 2. One end of the valve seat 2 is fixedly connected with a valve stem 5, and the bottom end of the valve stem 5 is nested with a valve flap 4;

[0021] It is characterized in that it also includes a column flange 15 and a driving device 16, the control end of the valve body 1 is embedded with a valve cover pre-tightening plate 22, and the valve cover pre-tightening plate 22 is embedded with a valve cover 6, The surface of the bonnet 6 is provided with a lock nut 9 along the circumference; the pre-tightening screw 10 is threadedly connected with the lock nut 9 and then presses against the end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com