Multi-point three-dimensional measurement-based boiler outlet smoke temperature real-time measuring method

A technology of three-dimensional measurement and real-time measurement, which is applied in the direction of measuring heat, measuring devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, and can solve problems that cannot meet the analysis of operating status and equipment status, and the measurement temperature is too low without correction. , unfavorable boiler combustion optimization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0078] see figure 2 , a method for real-time measurement of boiler outlet flue gas temperature based on multi-point stereo measurement, including the following operations:

[0079] 1) Build a multi-point stereo measurement system:

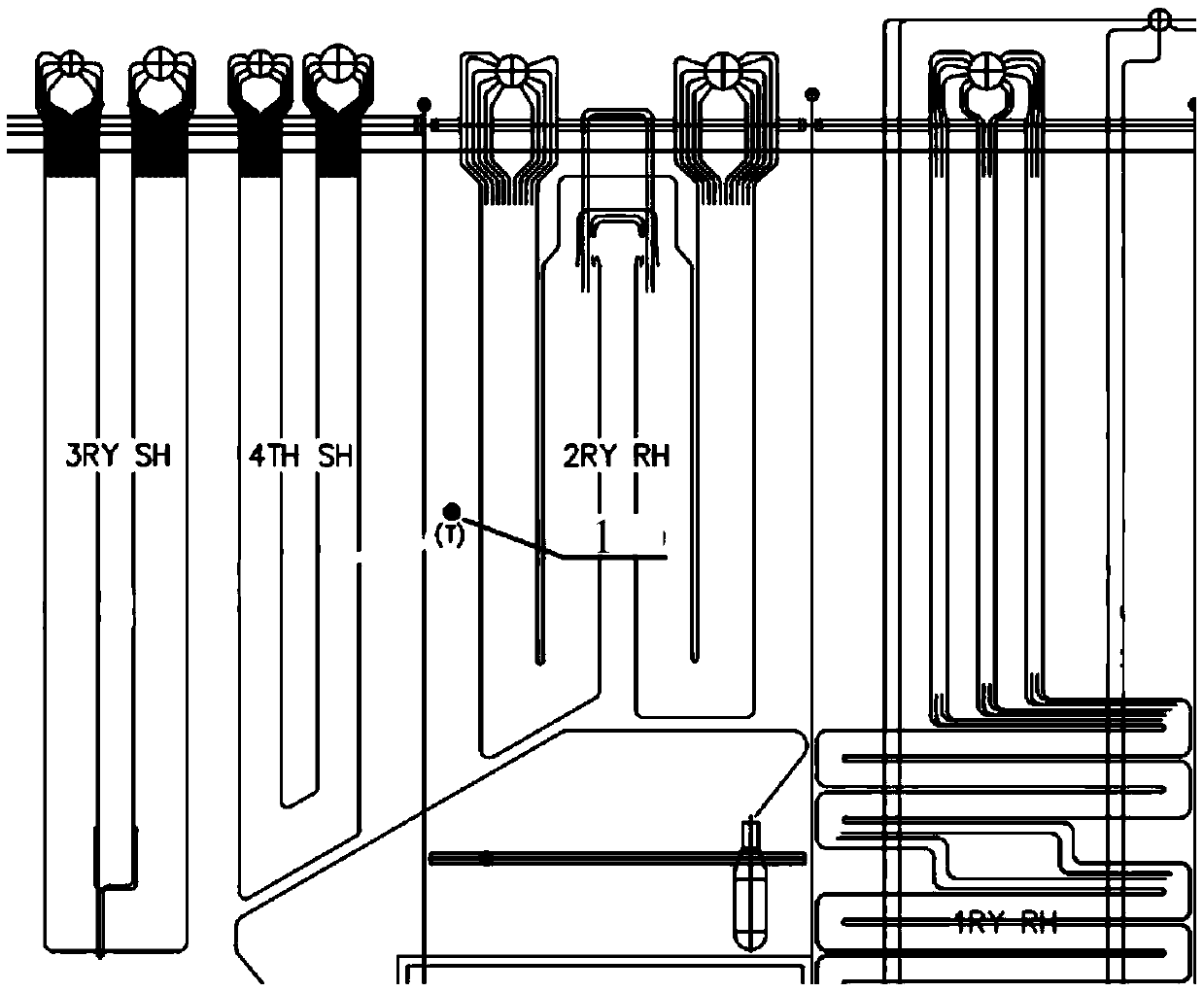

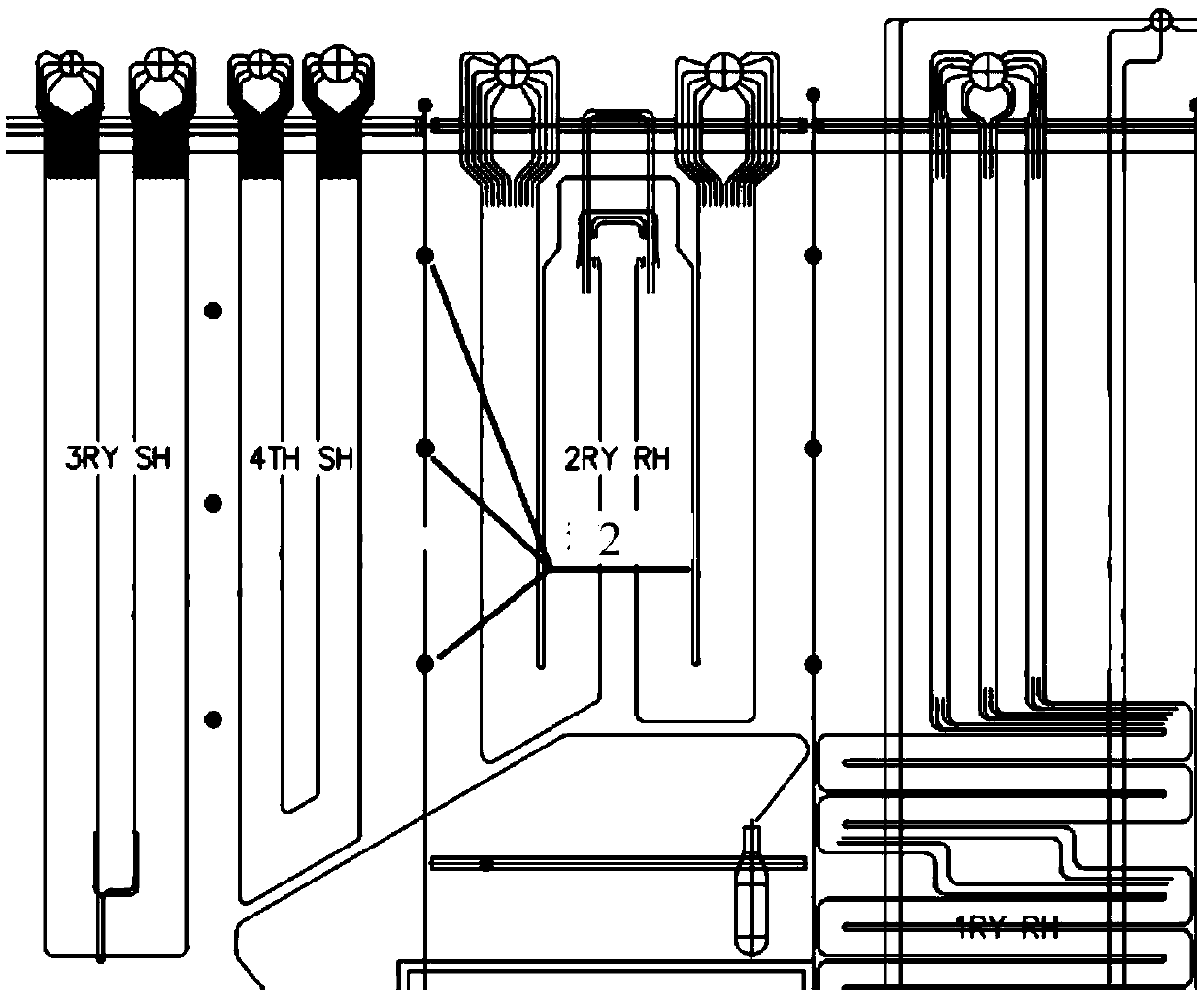

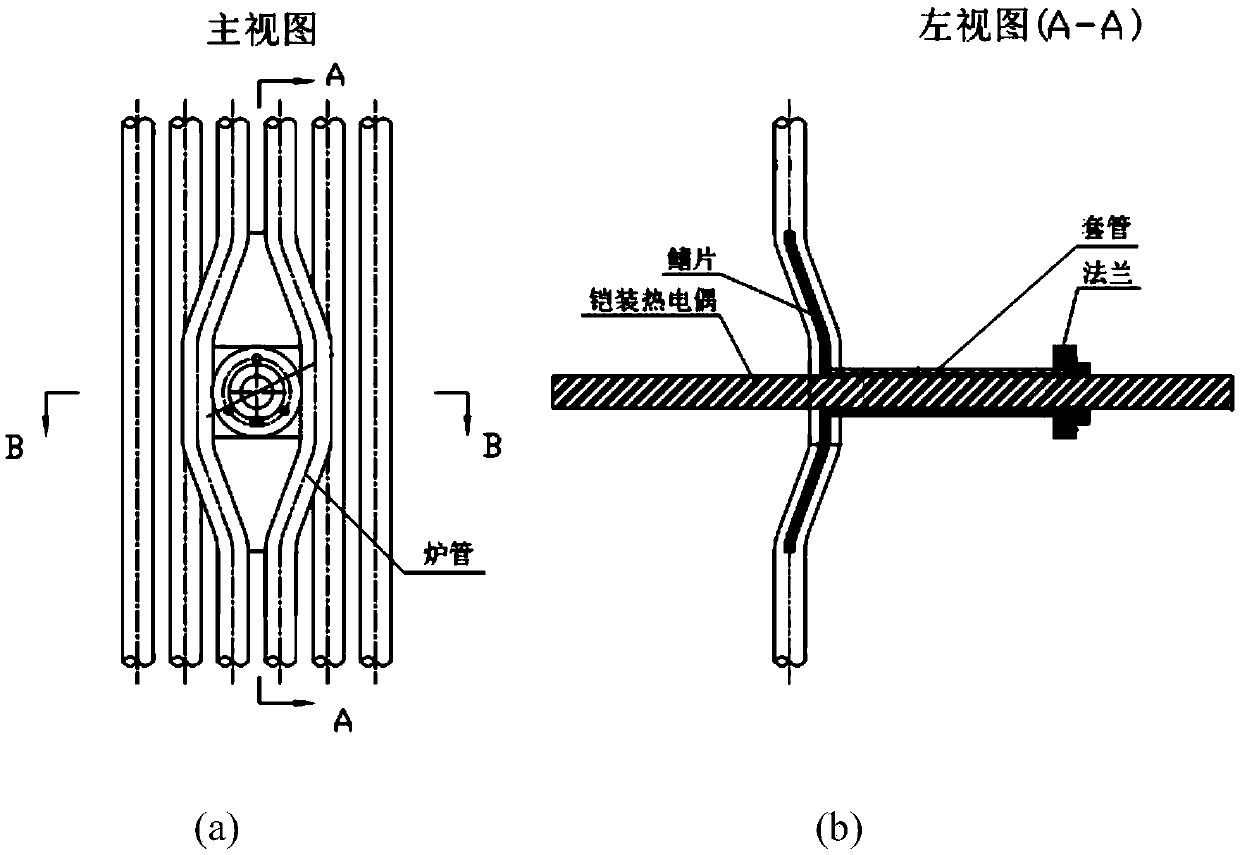

[0080] Set up multiple rows of smoke temperature measuring points in the horizontal flue of the boiler: set up a row of equidistantly distributed smoke temperature measuring points at the rear of the third-stage superheater, the fourth-stage superheater, and the second-stage reheater respectively. The temperature measuring point is equidistant from the front and rear heating surfaces; the smoke temperature measuring point adopts armored thermocouples for temperature collection;

[0081] Further, see figure 2 , install 18 smoke temperature measuring points in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com