Gantry-type X-ray nondestructive detection device

A non-destructive testing and X-ray technology, applied in measuring devices, using radiation for material analysis, using wave/particle radiation for material analysis, etc., can solve the problem of unsteady up and down motion, low precision, inaccurate image acquisition, and noise of counterweights and other problems to achieve the effect of simple structure, reliable operation and noise avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

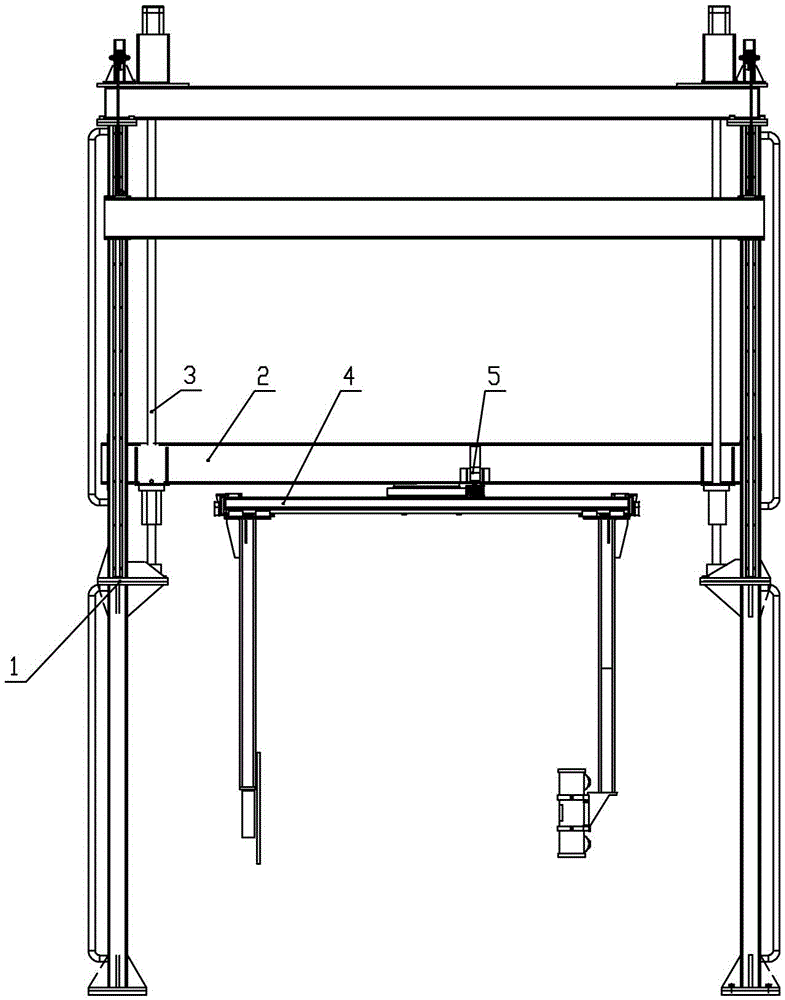

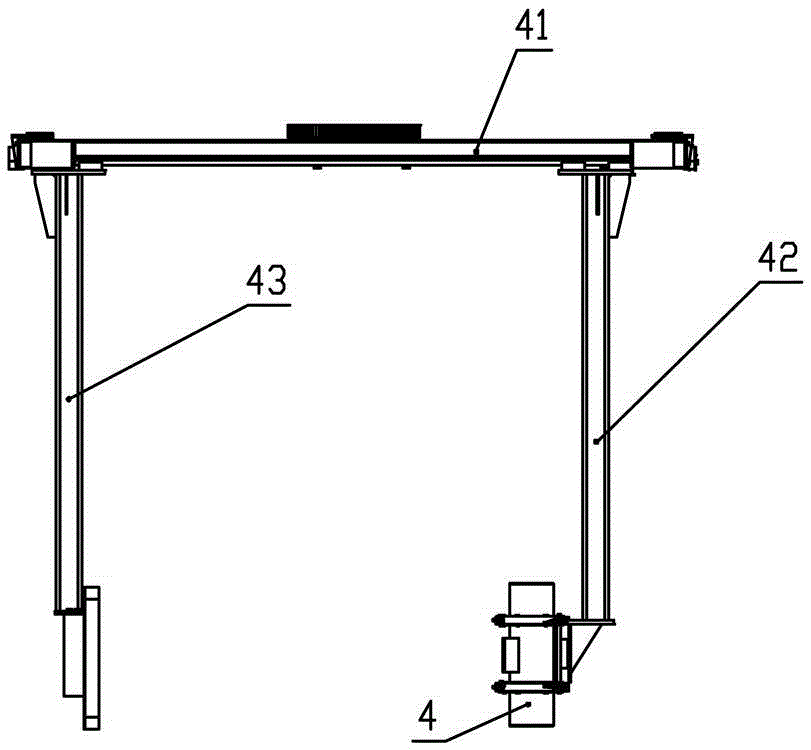

[0032] A gantry type X-ray non-destructive testing device, such as figure 1As shown, it consists of a gantry frame 1, a sliding beam mechanism 2, a sliding beam transmission mechanism 3, a C-arm mechanism 4 and a C-arm swing mechanism 5, wherein the sliding beam mechanism 2 and the sliding beam transmission mechanism 3 are installed on the gantry frame 1 Among them, the C-arm mechanism 4 and the C-arm swing mechanism 5 are installed in the sliding beam mechanism 2.

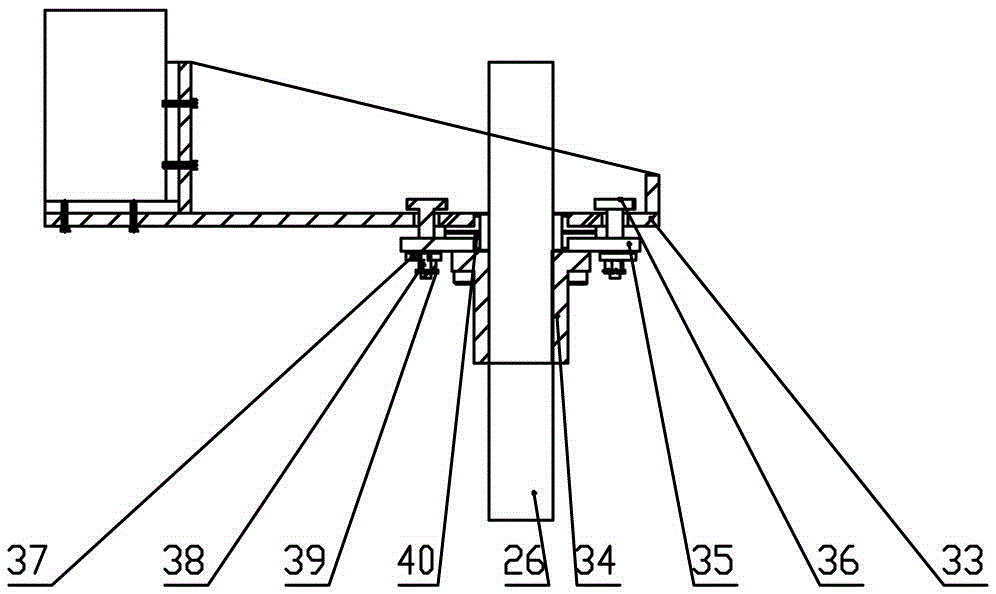

[0033] Gantry frame 1 as figure 2 As shown, it is composed of two lower vertical beams 6, two upper vertical beams 7 and a top beam 8, wherein the long rectangular lower vertical beam 6 is welded by a plurality of special-shaped steel pipes 9, as image 3 As shown, two handrails 10 are welded on the outside of the special-shaped steel pipe 9, and the upper and lower ends of the special-shaped steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com