Inserting tamping depth control device for cement concrete slump test

A cement concrete, depth control technology, applied in the direction of material inspection products, etc., can solve the problems affecting the test accuracy, difficult to control the insertion and tamping depth, etc., to achieve the effect of ensuring accuracy, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

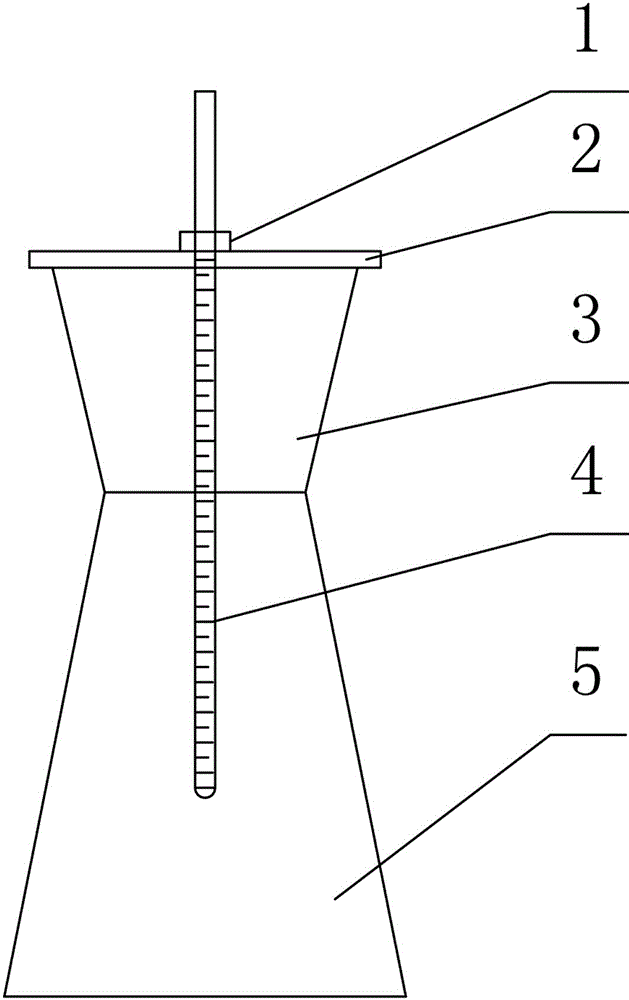

[0016] like Figure 1-3 As shown in , the cement concrete slump test inserts and tamps depth control device, the upper end of the tamping rod 4 with scale is covered with a positioning ring 1 that can move up and down along the tamping rod 4 with scale, and the lower end of the tamping rod 4 with scale passes through the charging funnel 3 The positioning hole on the top baffle plate 2 is inserted into the slump cylinder 5.

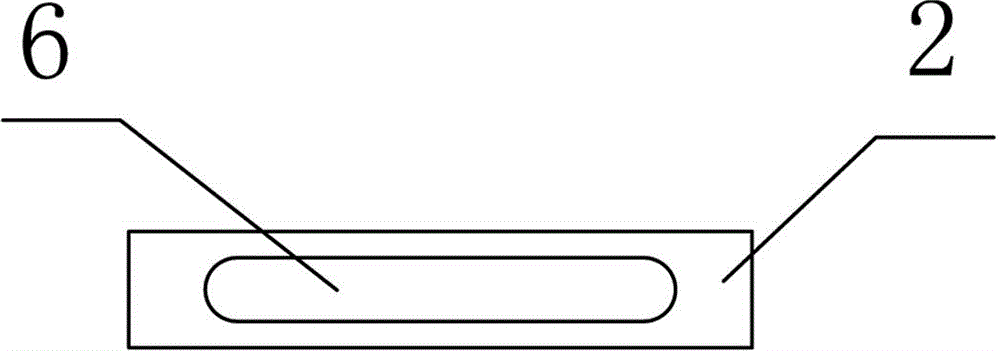

[0017] Preferably, the baffle 2 is a rectangular plate with a positioning hole 6 , and the length of the baffle 2 is greater than the diameter of the top surface of the charging funnel 3 .

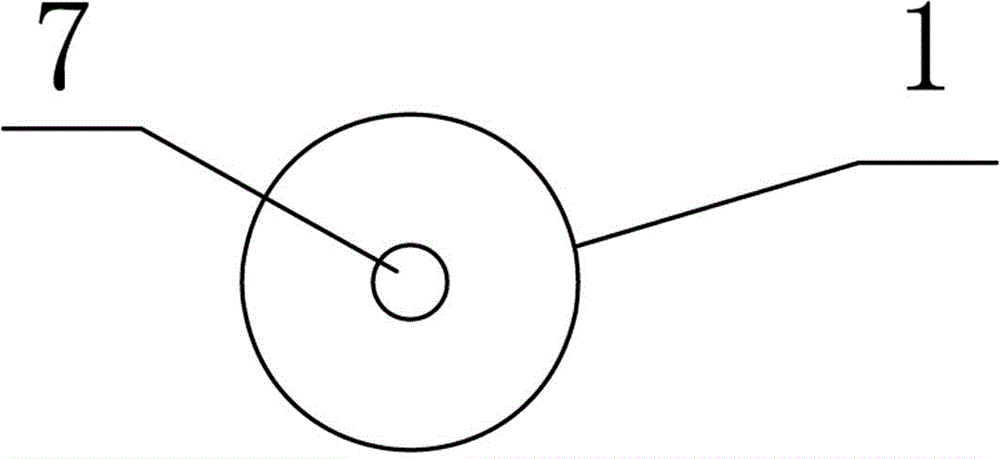

[0018] The locating ring 1 is a circular plate with a circular hole 7 , the circular hole 7 is in interference fit with the graduated tamper 4 , and the diameter of the locating ring 1 is larger than the width of the baffle plate 2 . The interference fit between the circular hole 7 and the tamping rod 4 with scale can make the positioning ring 1 be fixed on the desire...

Embodiment 2

[0024] The height of the slump cylinder 5 is 30cm, the height of the charging funnel 3 is 10cm, the thickness of the baffle plate 2 is 0.5cm, the height of the representative sample of the first layer of concrete in the slump cylinder 5 is 10cm, and the full length of the stamping rod 4 with scale is 60cm. And it is engraved with the scale line of 0 scale line at the top of the 4 hemispherical end of the stamping rod with scale, and the scale line of unit scale is 1mm. If it is necessary to penetrate through this layer and insert the lower layer to a depth of 2.5cm when inserting and pounding the second layer, the bottom surface of the positioning ring 1 should be fixed on the scale of the tamping rod 4 with a scale of 33cm (tube height 30+ funnel height 10+ baffle thickness 0.5 - The concrete sample height of the first layer is 10+, and it needs to be inserted into the lower layer at a depth of 2.5), so that when the second layer is penetrated, it can also be inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com