Semiconductor wafer teaching jig

A semiconductor and wafer technology, applied in the field of semiconductor wafer teaching fixtures, can solve the problems of difficulty in clearly confirming whether the finger arm is accurately grasping the wafer, normal insertion, installation and extraction, inconvenient, accurate measurement and correction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

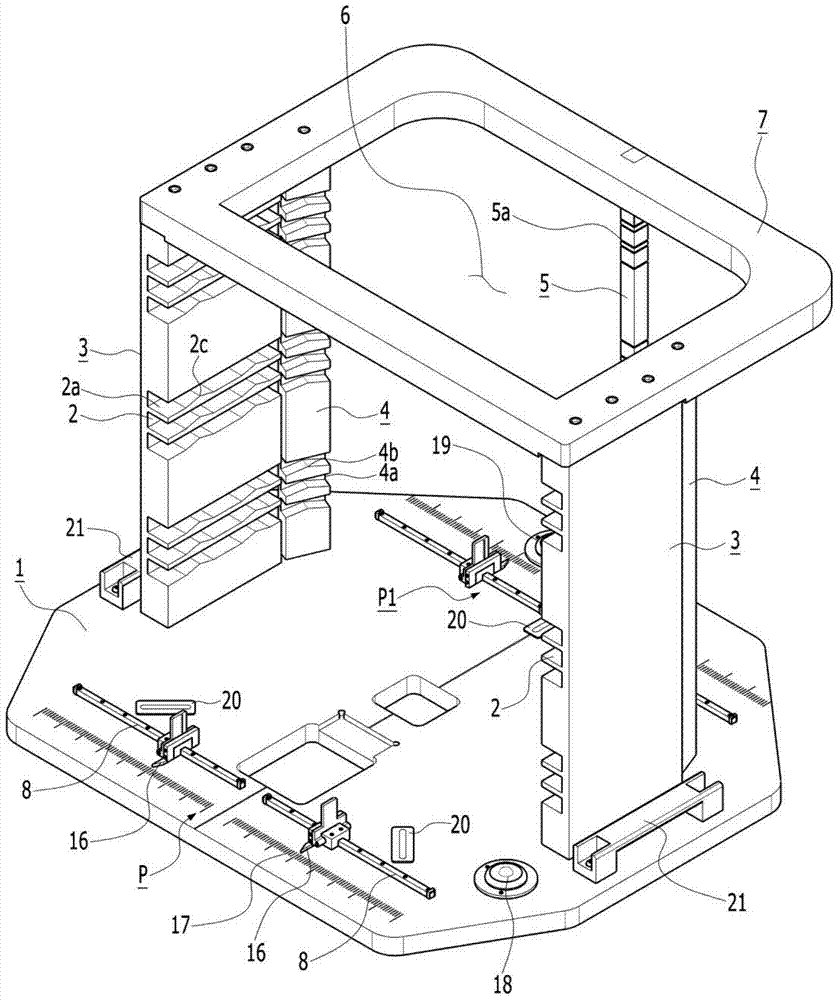

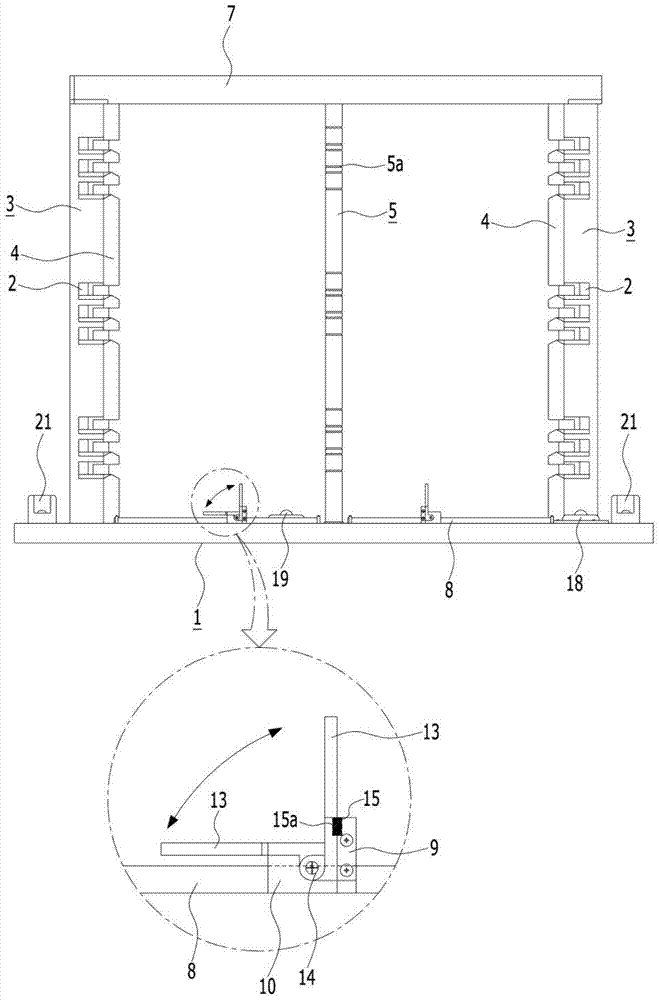

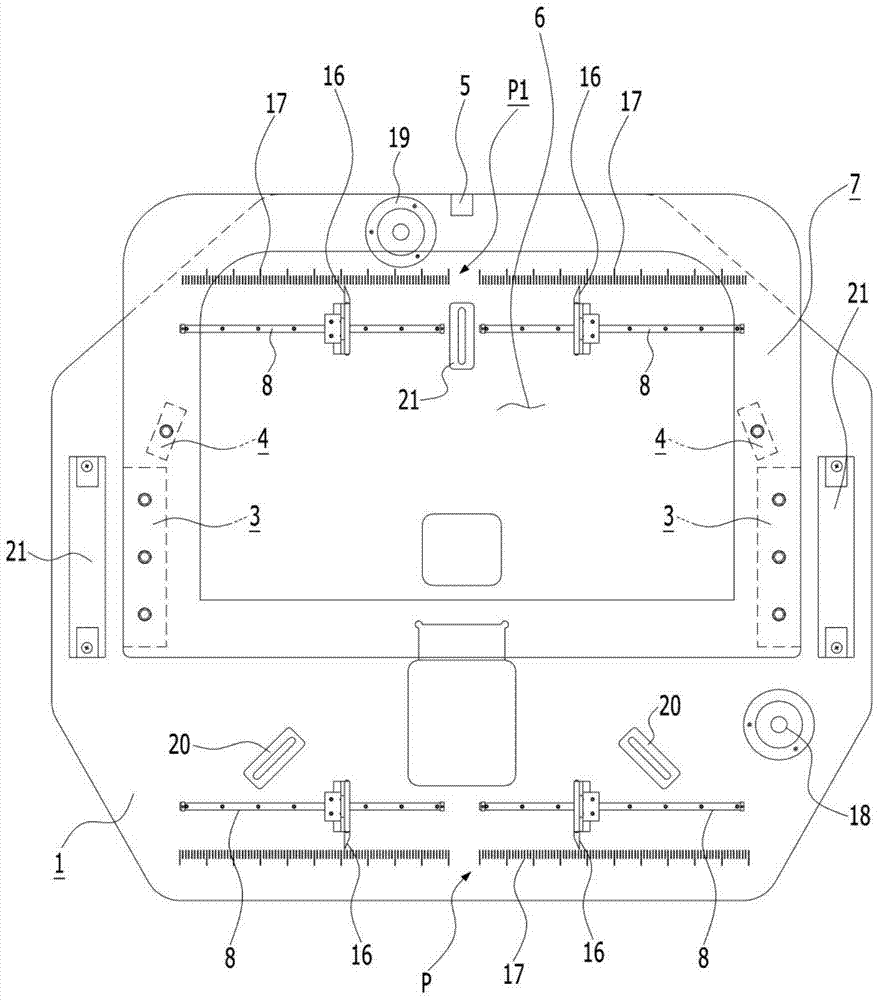

[0045] Below, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0046] The terms defined in the process of explaining the present invention are defined in consideration of the functions in the present invention, and cannot be regarded as limiting the technical constitution of the present invention.

[0047] The present invention can be variously modified and can have various embodiments, and in the following, the aspects will be described in detail. However, the present invention is not limited to a specific embodiment, and all modifications, equivalents, and substitutions belonging to the spirit and technical scope of the present invention are included.

[0048] In addition, the size and thickness of elements in each drawing are exaggerated or simplified to facilitate understanding, but the present invention is not limited to these drawings.

[0049] The terms used in the present application are used to illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com