Electric cable cutter

An outer sheath, electric technology, applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of not easy to cut through the outer sheath of the cable, troublesome construction personnel, and high work intensity, so as to improve personal safety. The effect of leveling, shortening cutting time and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

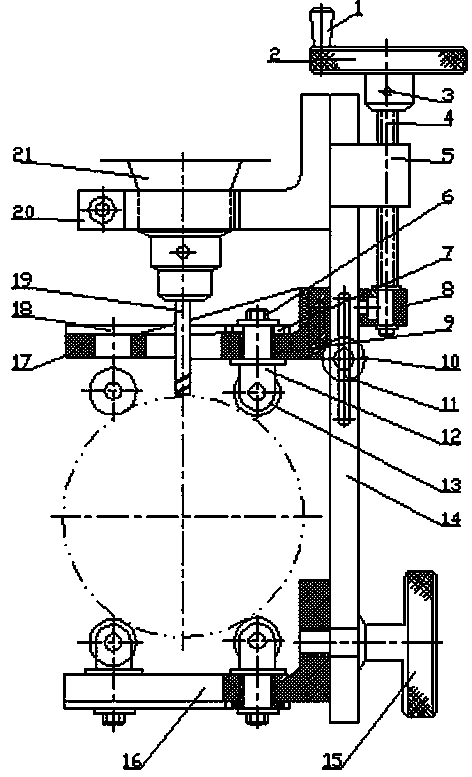

[0014] Such as figure 1 As shown in the electric cable sheath electric cutter, the power head 21 is connected to the power source, the power head 21 is installed on the power head bracket 20, the cutter 19 is installed on the power head 21, and the cutter 19 passes through the upper guide wheel bracket 17 and the outer surface of the cable. Sheath contacts. The power head support 20 is connected with the dovetail groove structure of the base plate 14 , the power head support 20 is connected with the feeding connecting block 5 , and the base plate 14 passes through the feeding connecting block 5 . The handle 1 is installed on the screw mandrel handwheel 2, and the handwheel 2 is connected with the feed screw mandrel 4 through the connecting pin 3. Feed screw mandrel 4 is connected with screw mandrel handwheel 2, and feed screw mandrel 4 is installed on the screw mandrel positioning block 8 through the knife feed coupling block 5, and screw mandrel positioning block 8 is instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap