Terminal-equipped wire and method of producing terminal-equipped wire

一种端子、电线的技术,应用在电路、导电材料、导电材料等方向,能够解决电蚀等问题,达到提高耐电蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

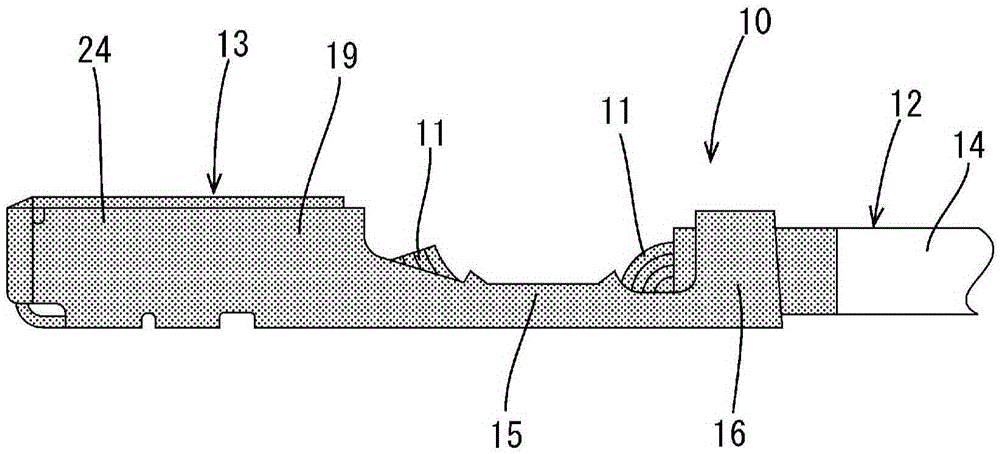

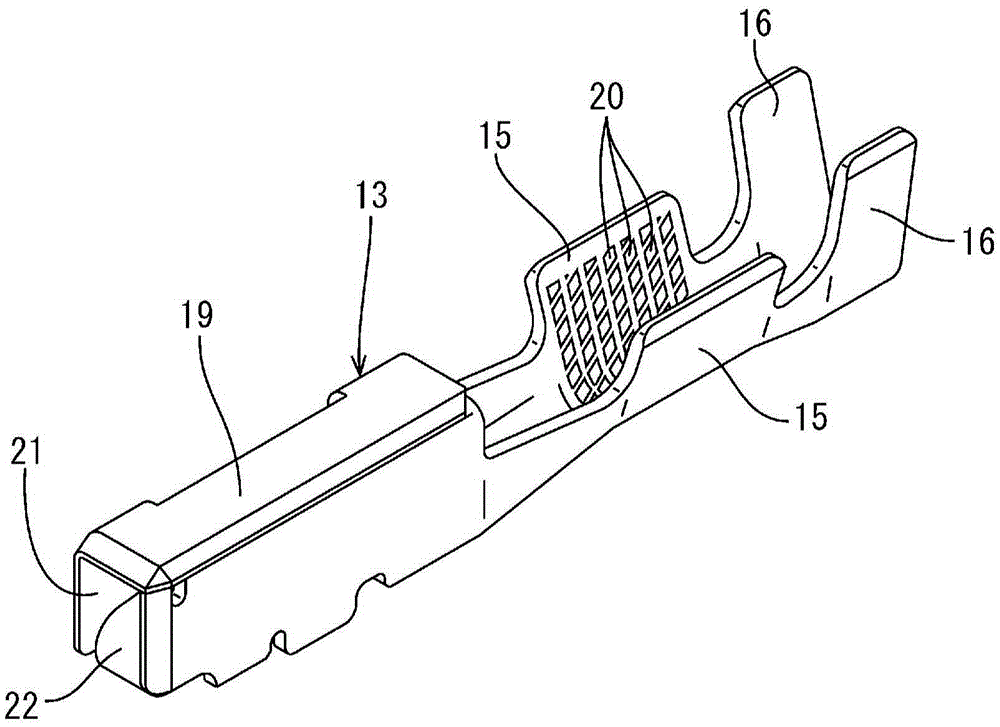

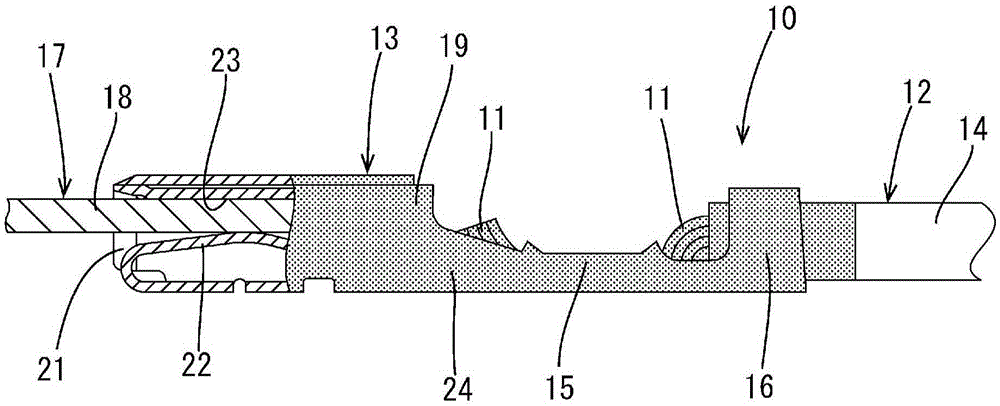

[0051] will refer to Figure 1-7 Embodiment 1 of the present invention will be described. The electric wire 10 with a terminal according to the present embodiment includes an electric wire 12 containing a core wire 11 containing a metal having a higher ionization tendency than copper and a terminal 13 containing copper or a copper alloy. It should be noted that in the following description, the figure 1 The left side of is called "front" and the right side is called "back".

[0052] wire 12

[0053]The electric wire 12 is obtained by surrounding the outer periphery of the core wire 11 with an insulating coating 14 made of synthetic resin. A metal having a higher ionization tendency than copper can be used as the metal constituting the core wire 11, and examples thereof include magnesium, aluminum, manganese, zinc, chromium, iron, cadmium, cobalt, nickel, tin, and lead, or alloys thereof . In this embodiment, the core wire 11 contains aluminum or an aluminum alloy. The c...

Embodiment approach 2

[0121] Next, we will refer to Figure 8 Embodiment 2 of the present invention will be described. The electric wire 40 with a terminal according to the present embodiment includes: a plurality of (two in the present embodiment) electric wires 42 each including a core wire 41 made of a metal member including an ionized Aluminum or an aluminum alloy which tends to be larger than copper; and a spliced terminal 43 (an example of the terminal 13 ) which contains copper or a copper alloy and is connected to a plurality of core wires exposed from the end of the electric wire 42 41. It should be noted that repeated descriptions in Embodiment Mode 1 are omitted.

[0122] In the present embodiment, the splicing terminal 43 includes a wire barrel portion 44 crimped to both of the two core wires 41 so as to wind the core wires 41 .

[0123] A plating layer (not shown) made of a metal for plating whose ionization tendency is closer to copper than to aluminum may be formed on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com