Easy-to-clean blocking structure for aluminum alloy casting

An easy-to-clean, aluminum-alloy technology, applied in casting equipment, mechanical cleaning, manufacturing tools, etc., can solve problems such as troublesome gas operation and failure to discharge scraps from the receiving tray in time, and achieve the effect of prolonging the cleaning cycle and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

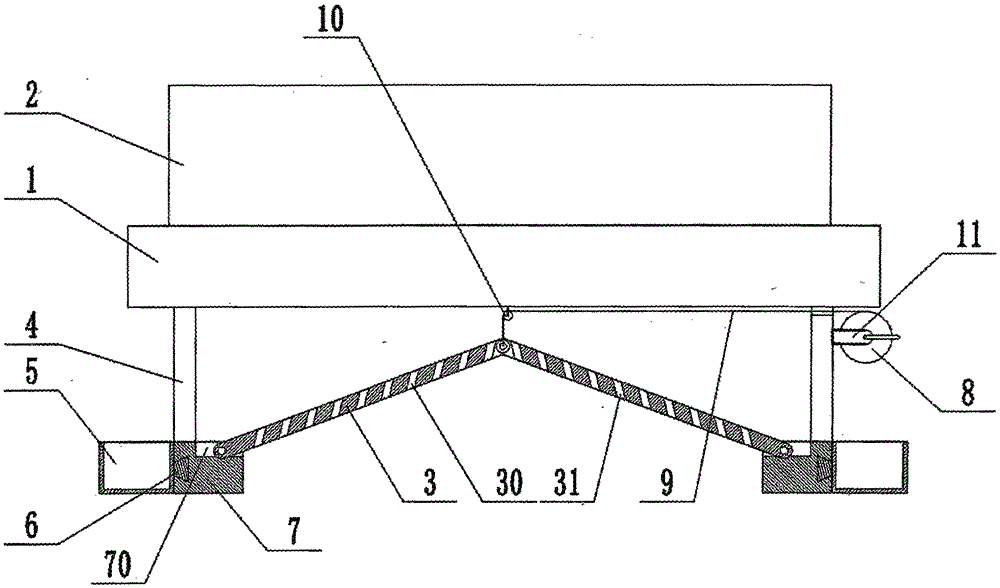

[0011] Such as figure 1 As shown, the easy-to-clean retaining structure for aluminum alloy casting in this embodiment, the retaining structure is installed below the base 1, and the casting plate 2 is installed above the base 1, and the retaining structure includes a tapered cross-section retaining plate 3 The baffle plate 3 includes two slanted baffles 30 arranged obliquely. The slanted baffles 30 are provided with filter holes 31 arranged vertically. In the groove 70; the upper surface of the end block 7 is fixedly connected with the base 1 through the connecting rod 4, and the outer surface is slidably installed with the receiving groove 5 through the dovetail groove sliding structure 6; Wheel 8, reel 8 is connected with the upper end of two oblique baffles 30 by winding rope 9 and the guide wheel 10 of base 1 lower surface.

[0012] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com