Thermoforming device and process of ring-shaped part formed by titanium alloy sheet

A titanium alloy, heat-setting technology, applied in aircraft parts, transportation and packaging, etc., can solve the problems that restrict the development and production of engines, and achieve the effect of improving forming accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

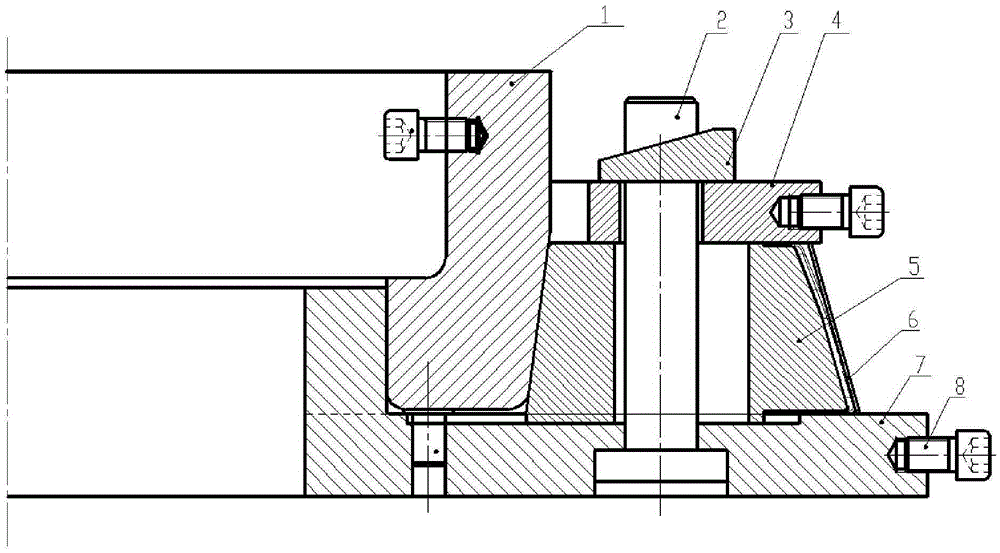

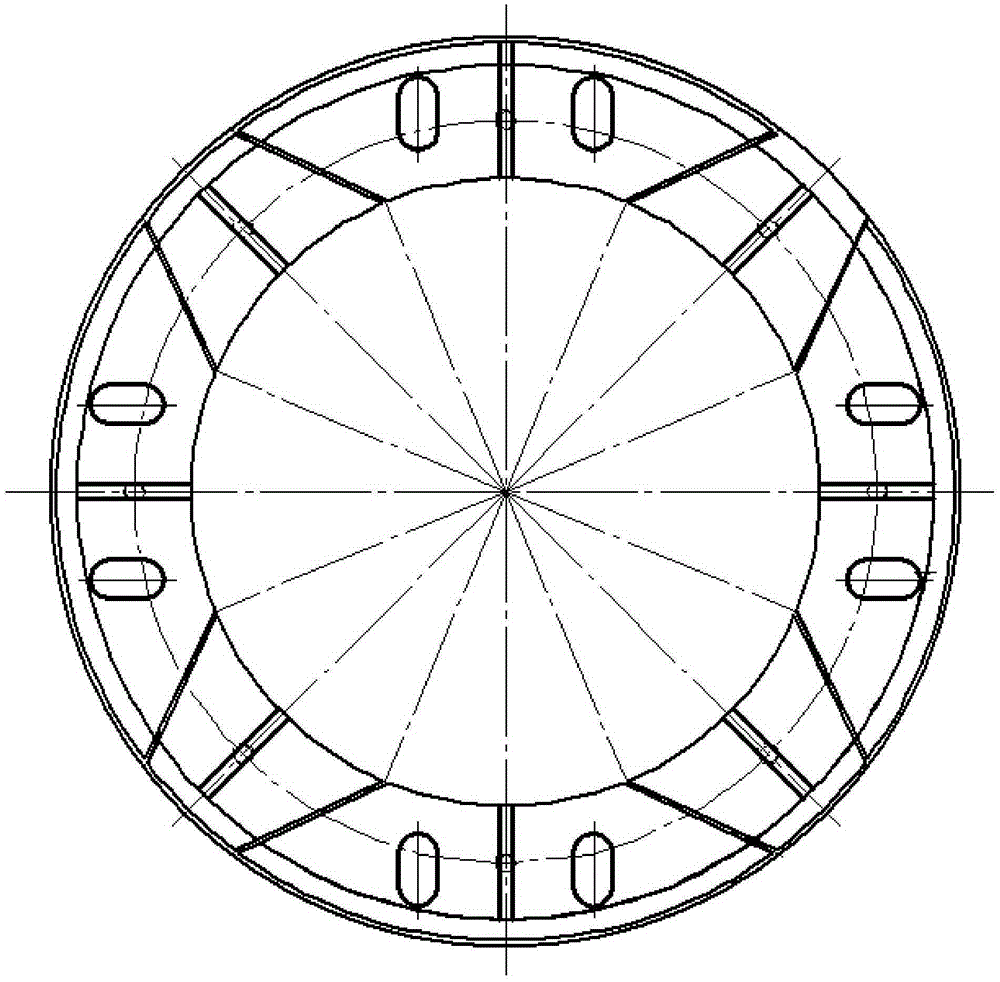

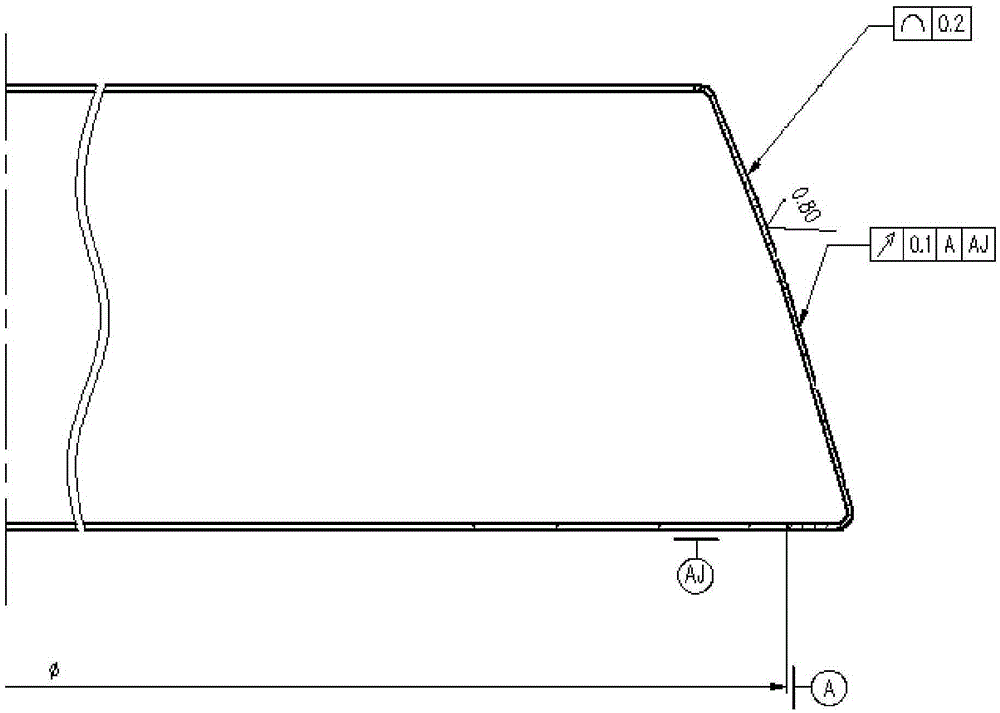

[0036] The heat-setting device for forming the titanium alloy sheet forming ring is as follows: an expanding cone ring 1, a positioning support column 2, a compression wedge 3, an upper limit plate 4, a shaping block 5, a limit ring 6, and a positioning bottom plate 7; The shaped block 5 is located between the upper limit plate 4 and the positioning bottom plate 7, the upper and lower ends of the shaped block 5 are compressed by the compression wedge 3 and the positioning support column 2, and the side ends of the shaped block 5 are passed through the expanding cone ring 1 and The limit ring 6 is compressed, and the upper limit plate 4 and the positioning bottom plate 7 are both provided with jacking screws 8 .

[0037] Titanium alloy sheet material forming ring piece heat setting process, using the titanium alloy sheet material forming ring piece heat setting device, the specific steps are as follows:

[0038] ①Using the stress relaxation thermoforming process, the part is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com