Automatic assembly tool for tool handle

An automatic assembly and handle technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of large space, high labor costs, time-consuming and labor-intensive, etc., to improve efficiency and yield, save labor costs and The effect of site costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

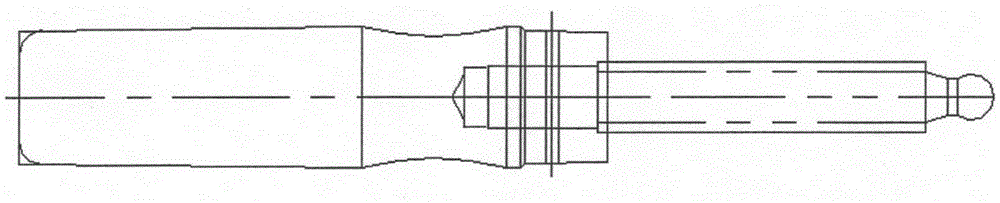

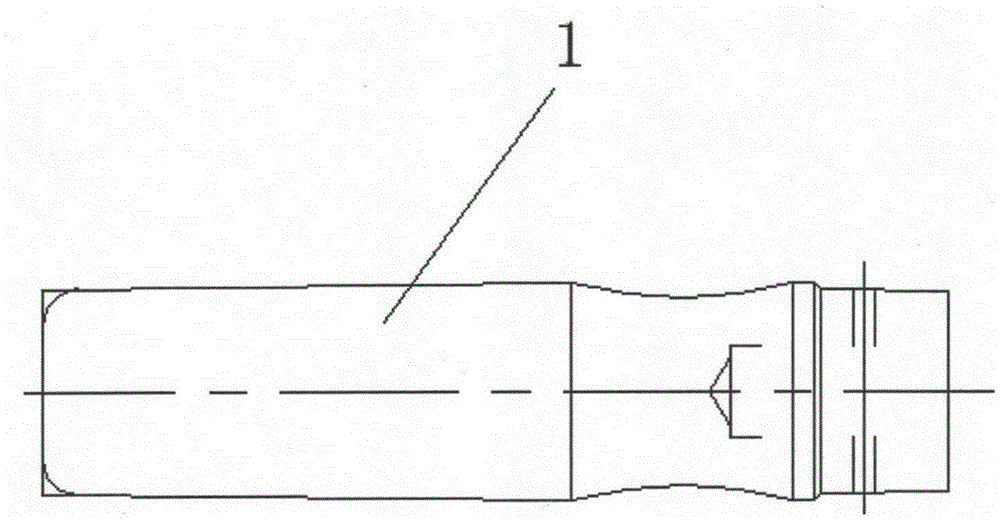

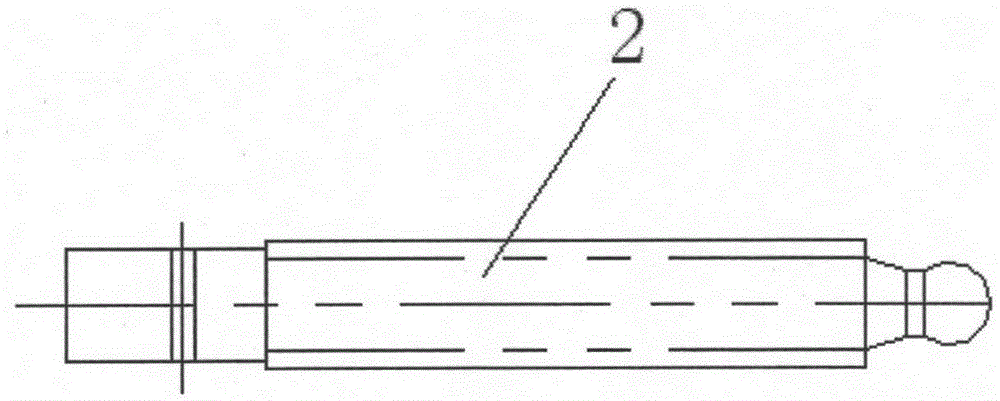

[0033] Such as image 3 As shown, the tool handle automatic assembly tool provided by the present invention is characterized in that it includes six clamps 4 for fixing the gripping part 1 and the connecting rod 2 . Such as Figure 5A and Figure 5B As shown, the fixture 4 includes a base plate 4-1, a V-shaped positioning block 4-2 is provided in the middle of the base plate 4-1, and a corner cylinder 4-3 is provided beside the V-shaped positioning block 4-2, and a Z-shaped pressing plate 4- One horizontal part of 4 is connected and fixed with the output shaft of the corner cylinder 4-3, and the other horizontal part of the Z-shaped pressing plate 4-4 presses and positions the connecting rod 2 in the V-shaped groove of the V-shaped positioning block 4-2, The front and rear sides of the V-shaped positioning block 4-2 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com