Sanding component

A sanding and component technology, applied in the field of sanding machines, can solve the problems of artificial sanding, poor bending strength, insufficient elasticity of sanding materials, etc., and achieve the effect of rich elasticity and good bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

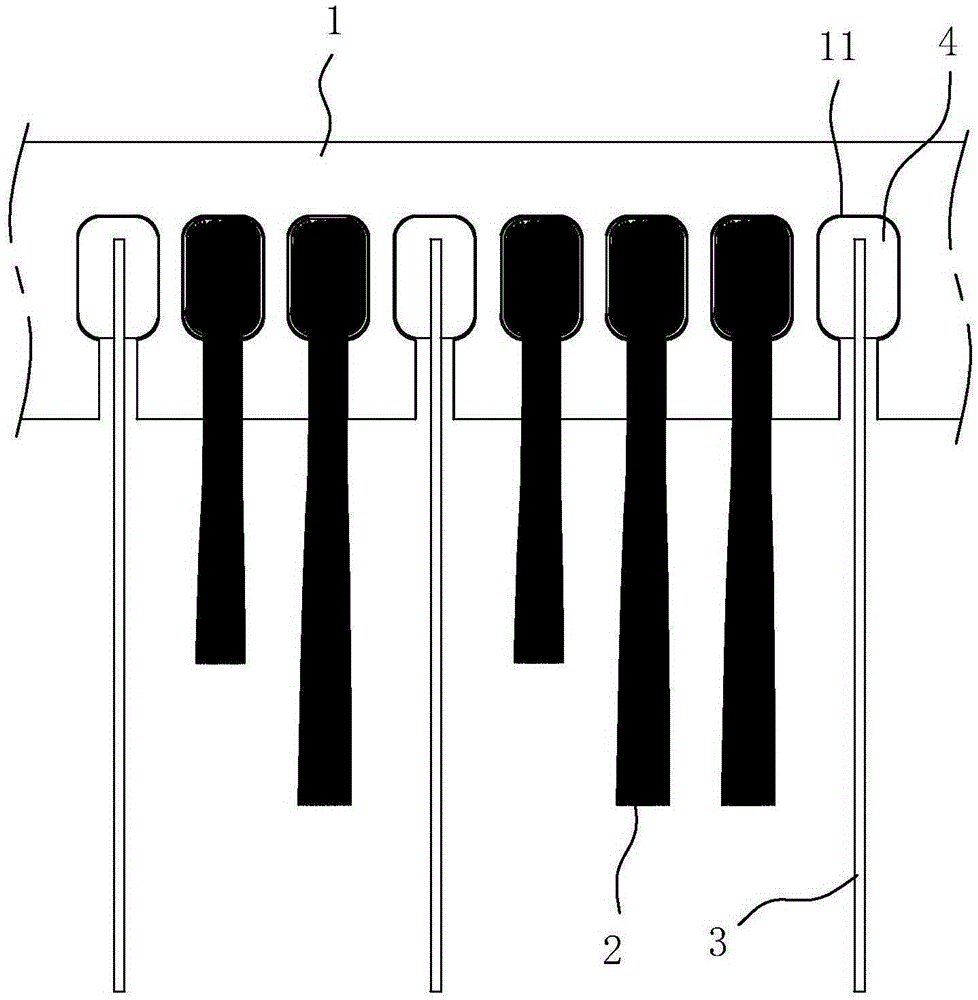

[0010] Such as figure 1 Shown, a kind of sanding component comprises base body 1, and the row sweep shape sisal fiber 2 and emery cloth 3 that are installed on base body 1 working surface, in the present invention, described emery cloth 3 is transverse to the direction that base body 1 rotates, And arranged at intervals along the rotation direction of the substrate 1 , at least one row of sisal fibers 2 are arranged on the back of the abrasive cloth 3 , and the height of the sisal fibers 2 is lower than that of the abrasive cloth 3 . When sanding, with the rotation of the sanding parts, the sisal fiber 2 sweeping against the back of the abrasive cloth 3 can provide good elastic support for the abrasive cloth 3, so that the abrasive cloth 3 will not bend, and the abrasive cloth 3 will always maintain the same height. The concave-convex curved surface of the drop is elastically contacted, and can complete most of the sanding of the transitional angles. Only some dead corners nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com