Grabbing gripper for three-way valve bodies

A three-way valve body and gripper technology, which is applied to manipulators, chucks, manufacturing tools, etc., can solve the problems of inconvenient operation, large three-way valve body, and heavy valve body weight, and achieves simple operation control and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0024] For the convenience of description, the rotation directions related to the gears and shafts related to the present invention are represented by Figure 4 as a reference standard.

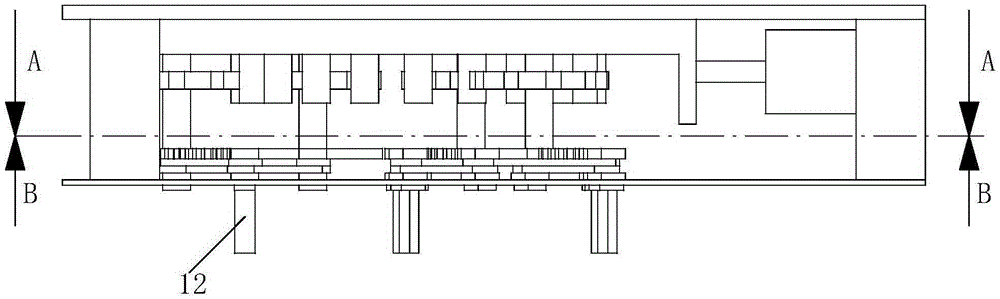

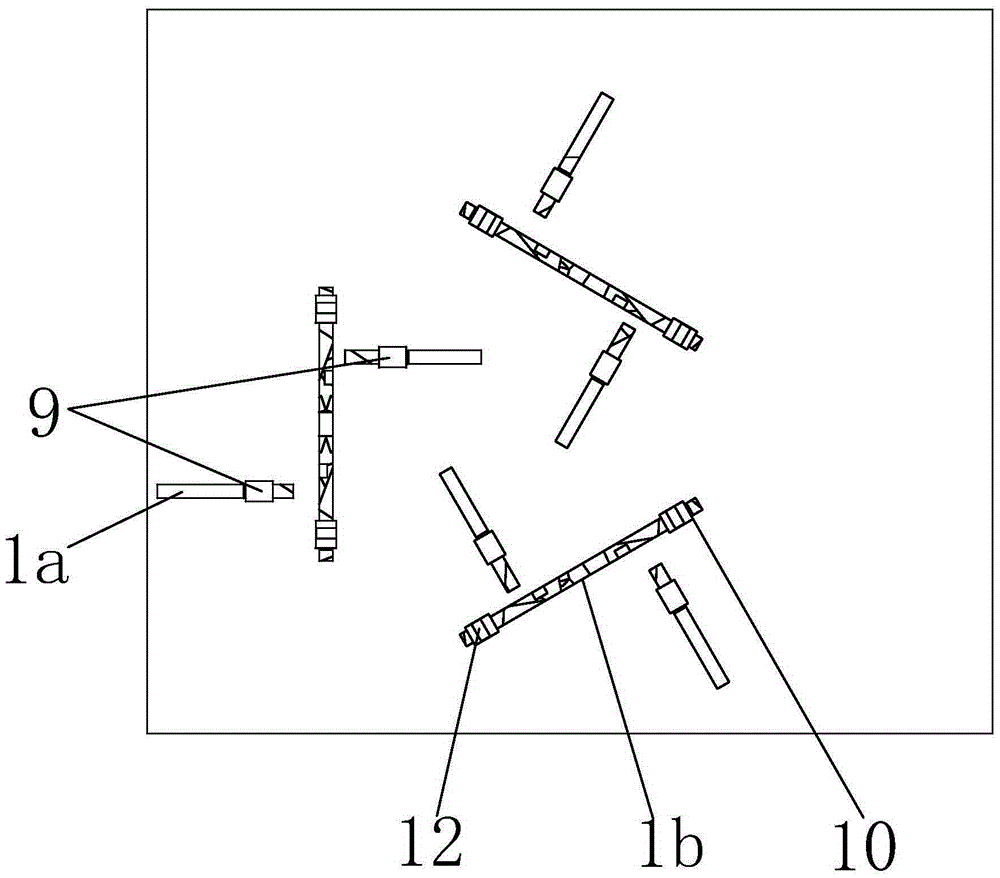

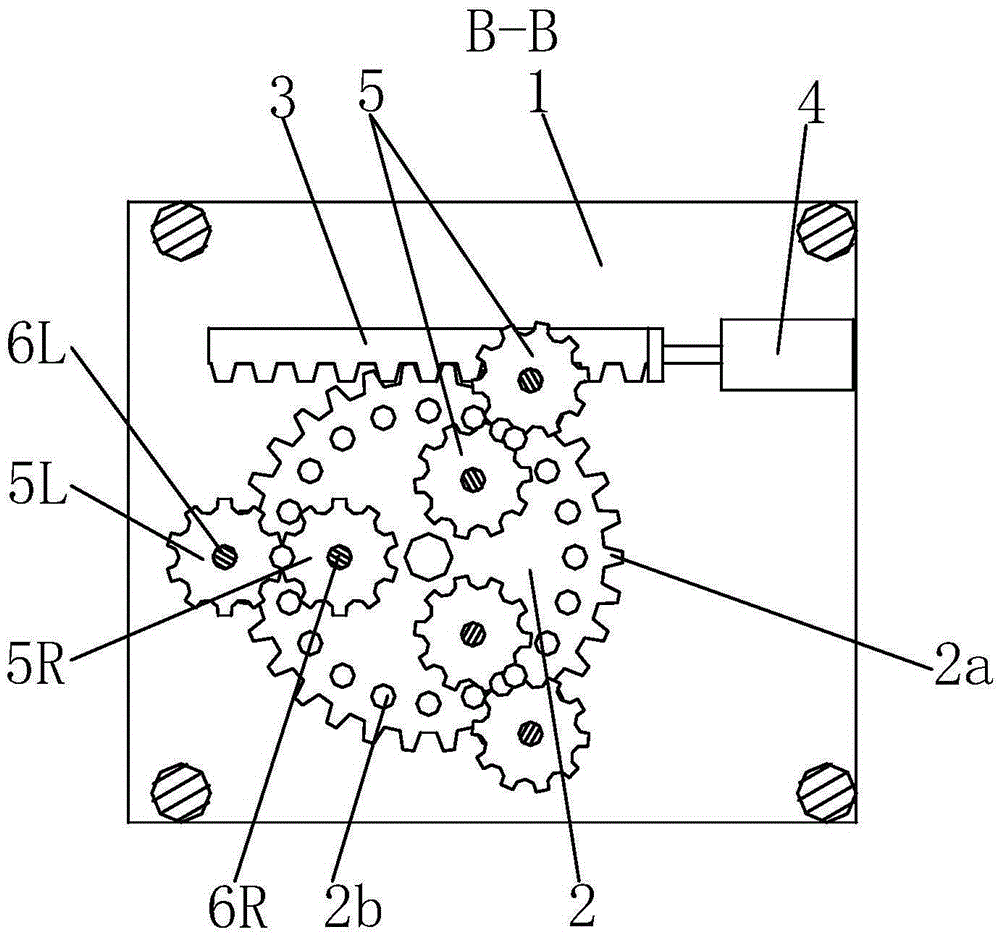

[0025] Such as Figure 1 to Figure 5 As shown, a gripper for extracting a three-way valve body mainly includes a box body seat 1 and a total drive wheel 2 installed in the center of the inner upper part of the box body seat 1. The arc end surface of the total drive wheel 2 is provided with a ring Teeth 2a, a ring of pin teeth 2b is arranged on the lower end surface of the total driving wheel 2 in a circular direction near the arc end.

[0026] The gear teeth 2 a are meshed with a rack 3 , and the rack 3 is connected with a cylinder 4 .

[0027] There are three pairs of gear sets 5 annularly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com