Fixable plastic extruding plate cooling frame

A technology of extruded plastic plate and cooling rack, applied in the field of extruded plastic plate cooling rack, can solve the problem of extruded plastic plate being easily blown off, and achieve the effect of good position control and prevention of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

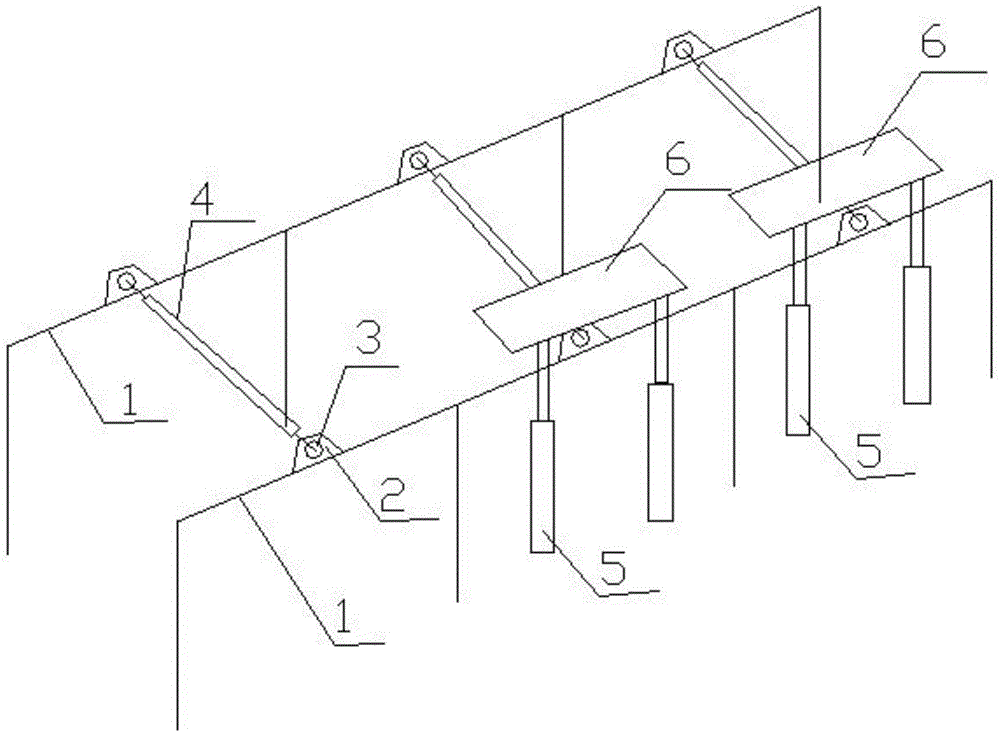

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] A fixed extruded board cooling frame includes a base, and the base includes two rows of identical and parallel side frames 1, bearing seats 2 are arranged at intervals on the side frames, and the two sides The bearing seats 2 on the frame have the same position distribution, and they belong to the bearing seats 2 on the two side frames to form a group correspondingly. The bearing seats 2 are fixed with bearings 3; they also include connecting round rods 4, connecting round rods 4 The two ends go through the bearing 3 in the bearing block 2 belonging to the same group. Wherein the outer side of side frame 1 of a row is provided with fixing device, and described fixing device comprises pressing plate 6 and hydraulic oil cylinder 5, and described hydraulic oil cylinder 5 is placed vertically and arranged in a row along side frame 1 evenly spaced, and described pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com