Ground wire protecting box

A technology for protecting boxes and ground wires, which is applied to internal accessories and other directions, and can solve problems such as ground wires being prone to bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

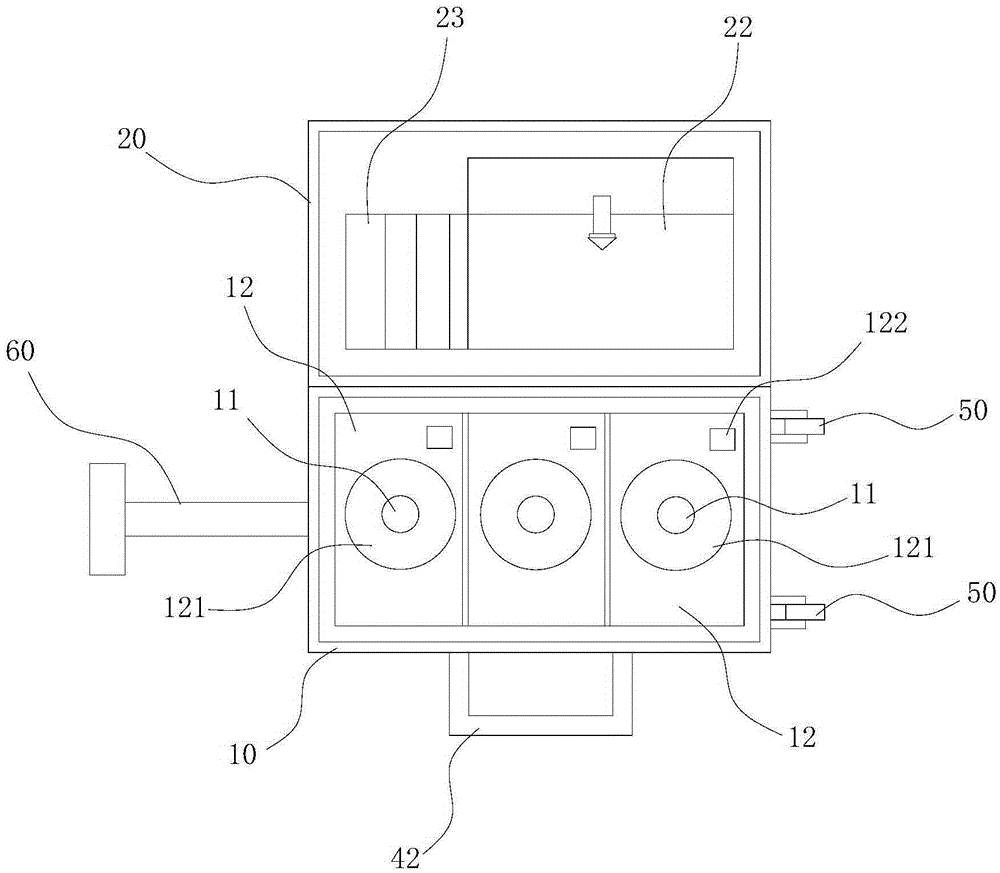

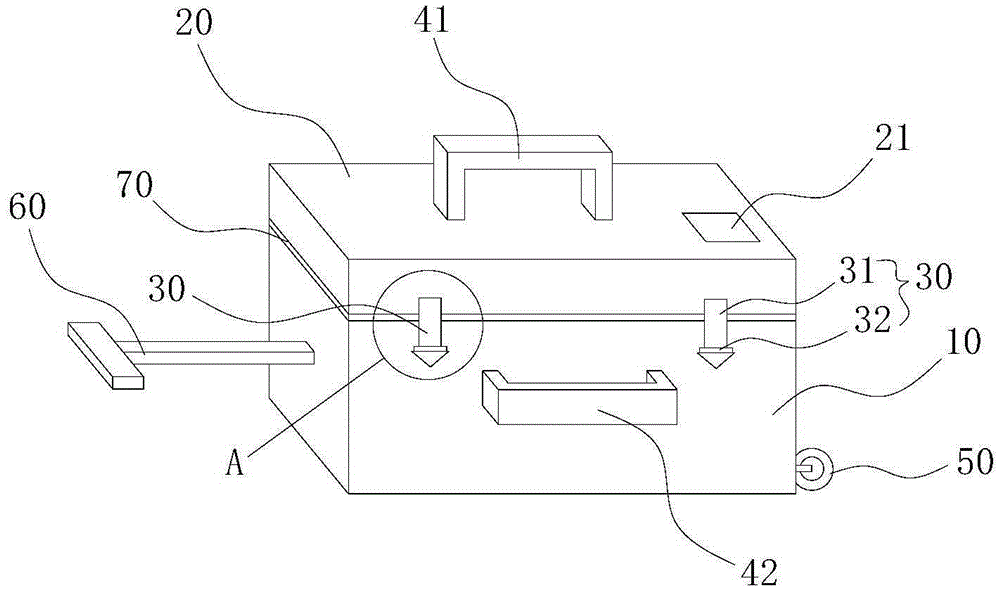

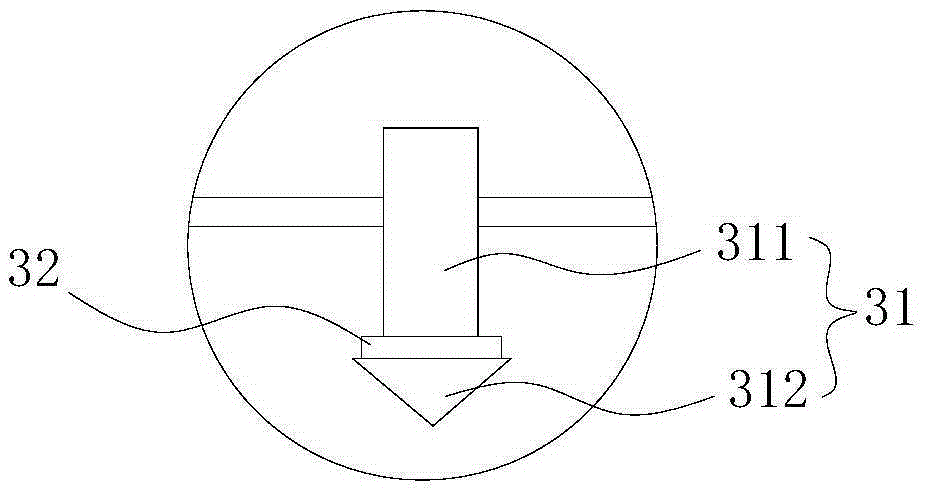

[0022] Such as figure 1 As shown, the ground wire protection box of this embodiment includes a box body 10 , a partition and a box cover 20 . Wherein, the box body 10 has a cavity inside. The separator is arranged in the cavity and divides the cavity into multiple ground wire accommodation cavities. A winding boss 11 is provided in the middle of each ground wire receiving chamber, and a cover plate 12 is provided at the opening of each ground wire receiving chamber. The cover plate 12 has an escape notch 121 for avoiding the winding boss 11 . A winding operation space is formed between the edge of the escape notch 121 and the circumferential outer surface of the winding boss 11 . The box c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com