Rock burst prevention steel structural part roadway support shrinkage structure

A technology of steel structure parts and roadway support, which is applied in the direction of pillars/supports, mining equipment, earthwork drilling and mining, etc. It can solve the problems of no continuous support for the cross section of the roadway, no support provided by the side, and no support alone, etc., to achieve Reduced maintenance workload, extensive practicability, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Steel structure refers to the connection of various steel parts by welding, riveting and bolting into a whole. These steel parts are interconnected and restricted to form an organic whole.

[0044] Based on the same principle, the present invention provides two types of retractable support structures for steel structures:

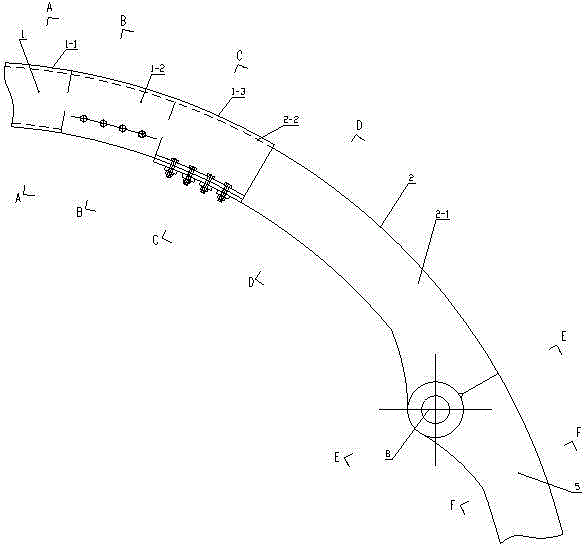

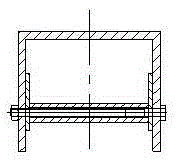

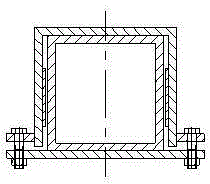

[0045] The compressible structure of the roadway support for the impact-resistant ground pressure steel structure of the present invention is divided into two forms: the curved structure of the shrinkable support of the steel structure and the linear structure of the shrinkable support of the steel structure, both of which include a first connecting pipe and a second Two connecting pipe.

[0046] The first form:

[0047] The curved structure of the shrinkable support of steel structure (referred to as the curved structure) is the first form, which can be used for the curved part of the roadway support.

[0048] Such as figure 1 , 4 , 5 and 1a~e, Figure 1a ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com