semi-active hydraulic mount

A hydraulic mount, semi-active technology, applied in the direction of shock absorbers, springs, springs/shock absorbers, etc., can solve the problems of inability to meet shock absorption requirements, complex structure, high cost, and achieve simple structure, good reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

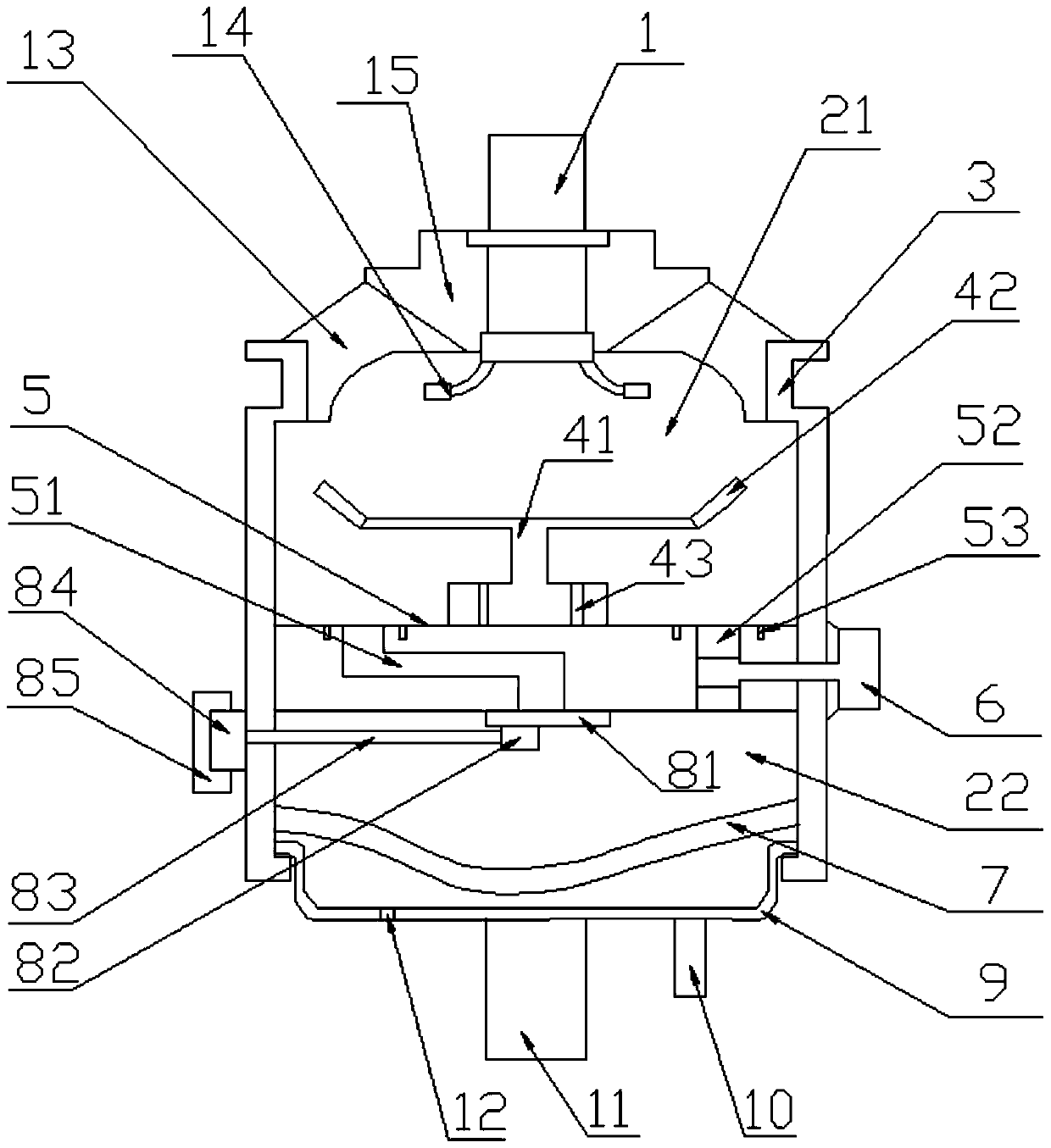

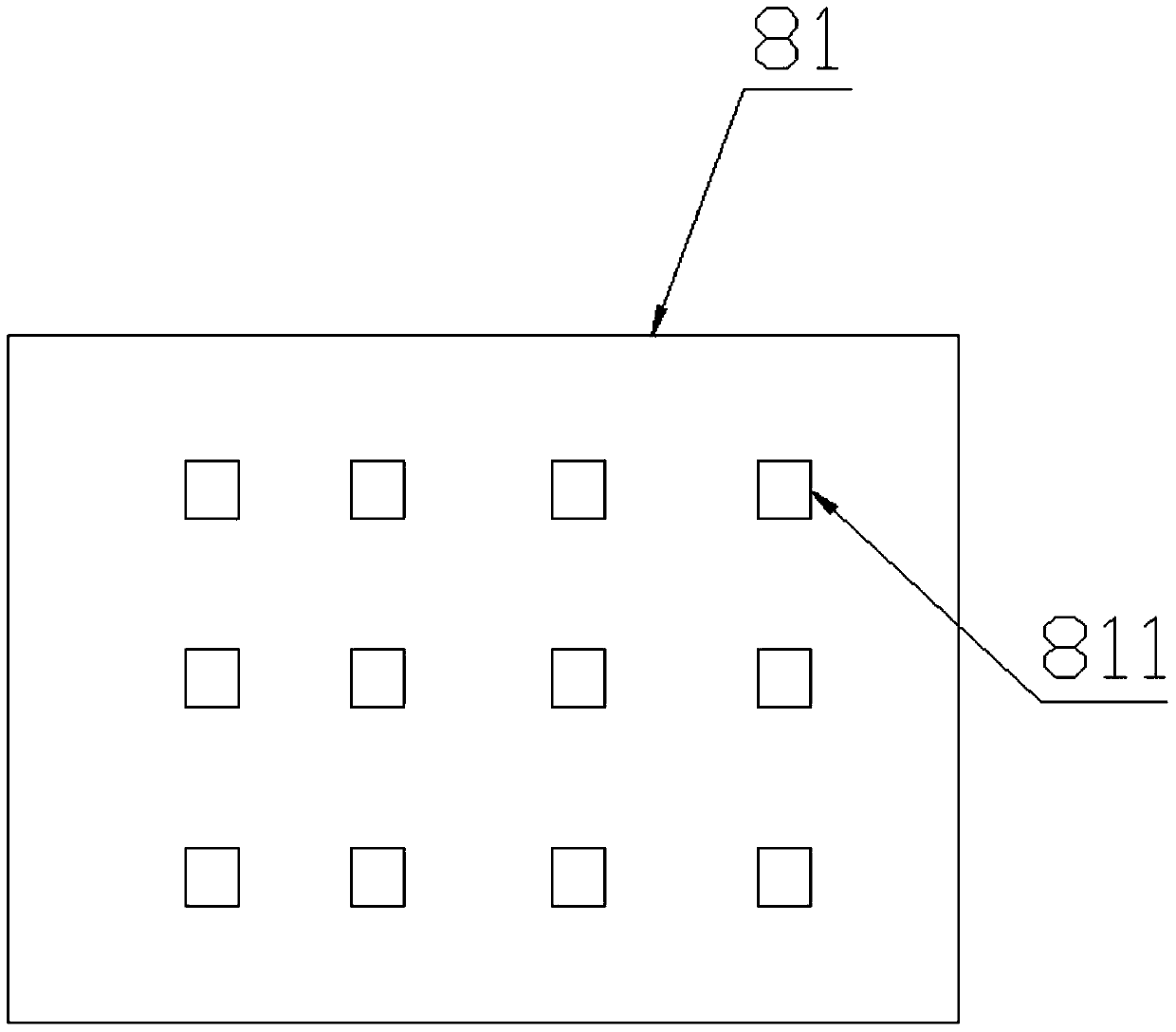

[0019] Semi-active hydraulic mounts, such as Figure 1-2 Shown, comprise rubber main spring 13, housing 3 and base film 7, rubber main spring 13, housing 3 and base film 7 encircle a cavity, be provided with vibration isolation mechanism 5 in the cavity, vibration isolation mechanism 5 will cavity Divided into an upper liquid chamber 21 and a lower liquid chamber 22, a first channel 51 and a second channel 52 are provided in the vibration isolation mechanism 5, and a cover plate 81 is arranged below the first channel 51 on the vibration isolation mechanism 5, and a cover plate 81 is provided on the cover plate 81. There are ten square holes 811, the housing 3 is provided with a motor 84, the motor 84 is provided with a lifting shaft 83, and the lifting shaft 83 is provided with a current limiting block 82, and the current limiting block 82 controls the closing of the square holes 811. The current limiting block 82 controls the flow rate of the liquid in the first channel 51 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com