Elevator traction machine shock absorber based on multi-layer metal rubber and its working method

A technology of elevator traction machine and metal rubber, which is applied to elevators, springs/shock absorbers, mechanical equipment, etc. in buildings, and can solve problems such as difficult offset of shock absorbing devices, attenuation of elastic material life, loss of original performance, etc. , to achieve the effects of slowing down the vibration amplitude, improving the service life, and long fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

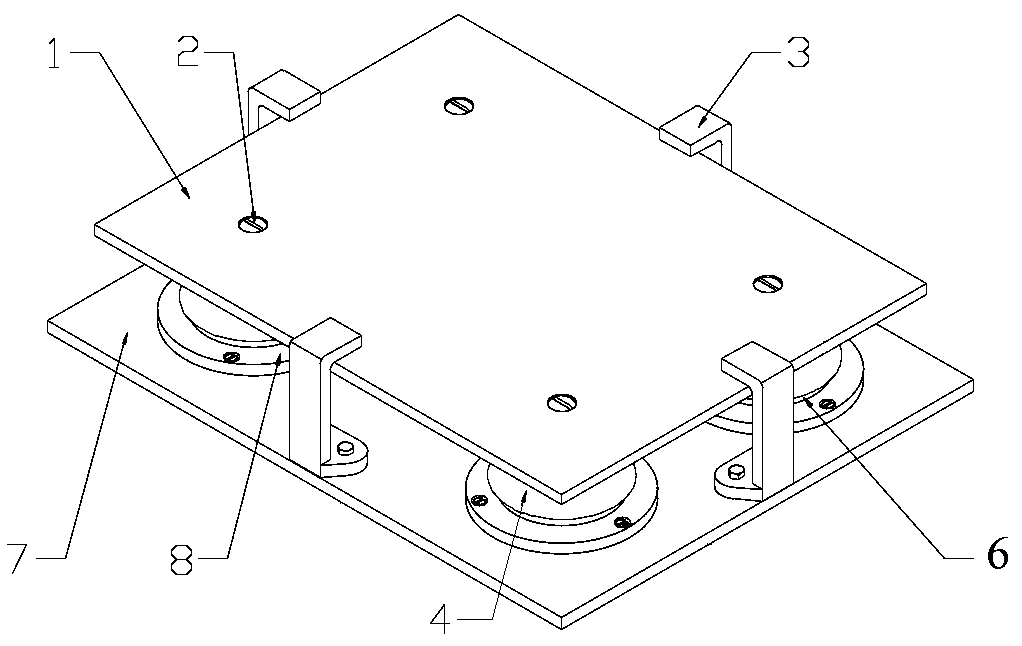

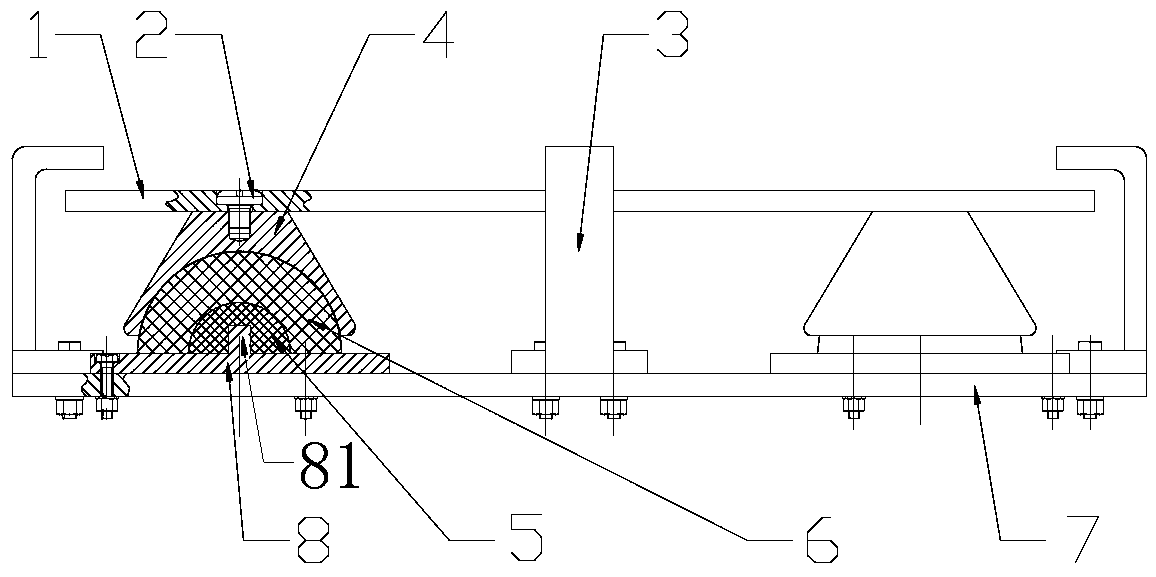

[0022] Such as Figure 1~2 As shown, a multi-layer metal rubber-based elevator traction machine shock absorber includes a base 7, and at least four shock pad fixing seats 8 are symmetrically arranged on the upper end surface of the base 7, and the shock absorbing pad fixing seats 8 center is provided with boss 81, is provided with hemispherical high-density metal rubber 5 on the top of shock-absorbing pad fixing seat 8, is provided with the center of shock-absorbing pad fixing seat 8 in the center of the lower plane of high-density metal rubber 5. Boss 81 cooperates to be beneficial to limit the groove that high-density metallic rubber 5 slides, and the top of high-density metallic rubber 5 is provided with the low-density metallic rubber 6 that is hemispherical shape, is provided with in the lower plane center of low-density metallic rubber 6 Hemispherical grooves matched with high-density metal rubber 5 hemispherical surfaces.

[0023] In this embodiment, above the low-dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com