Edge position detection device and edge position detection method

An edge position and detection device technology, applied in the field of edge position, can solve the problems of smaller gradient, lower contrast, and inability to detect edge position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

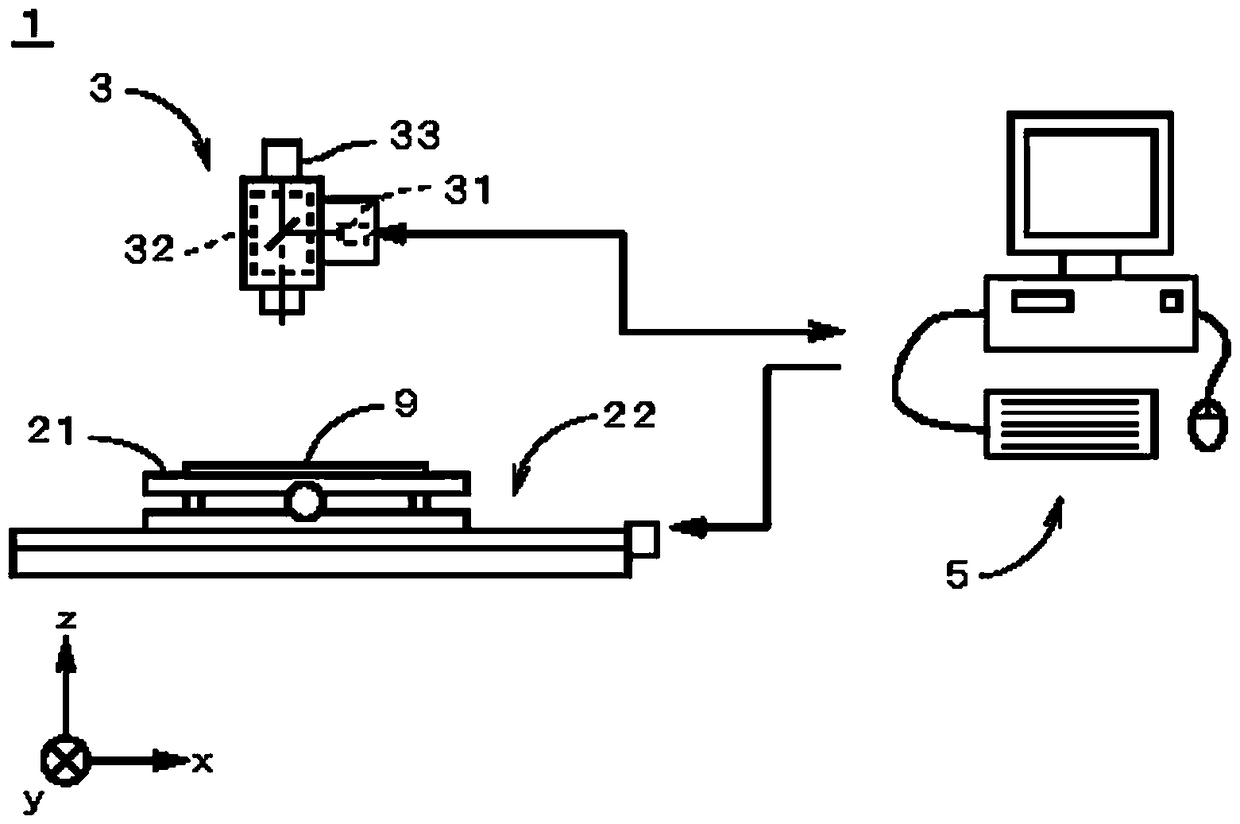

[0045] figure 1 It is a diagram showing a schematic configuration of a pattern measuring device 1 according to an embodiment of the present invention. The pattern measurement device 1 measures the width (namely, line width) of a linear pattern unit on a pattern formed on an object, that is, a semiconductor substrate, a glass substrate, or a printed circuit board (hereinafter, simply referred to as "substrate 9"). Automatic length measuring machine.

[0046] The pattern measuring device 1 has a table 21 , a table driving unit 22 , and an imaging unit 3 . The table 21 is used to hold the substrate 9 . The table drive unit 22 relatively moves the table 21 with respect to the imaging unit 3 . The table driving unit 22 is composed of a ball screw, a guide rail, a motor, and the like. The imaging unit 3 is disposed above the table 21 (ie, on the (+z) side), and captures image data of an inspection target region on the substrate 9 . The imaging unit 3 has an illumination unit 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com