Bearing assembly for an intermediate shaft in a clutch of a hybrid module

A technology of hybrid power module and separation clutch, which is applied in the direction of power plant, hybrid vehicle, air pressure power plant, etc., and can solve the problems of increasing structural space and excessive demand for structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

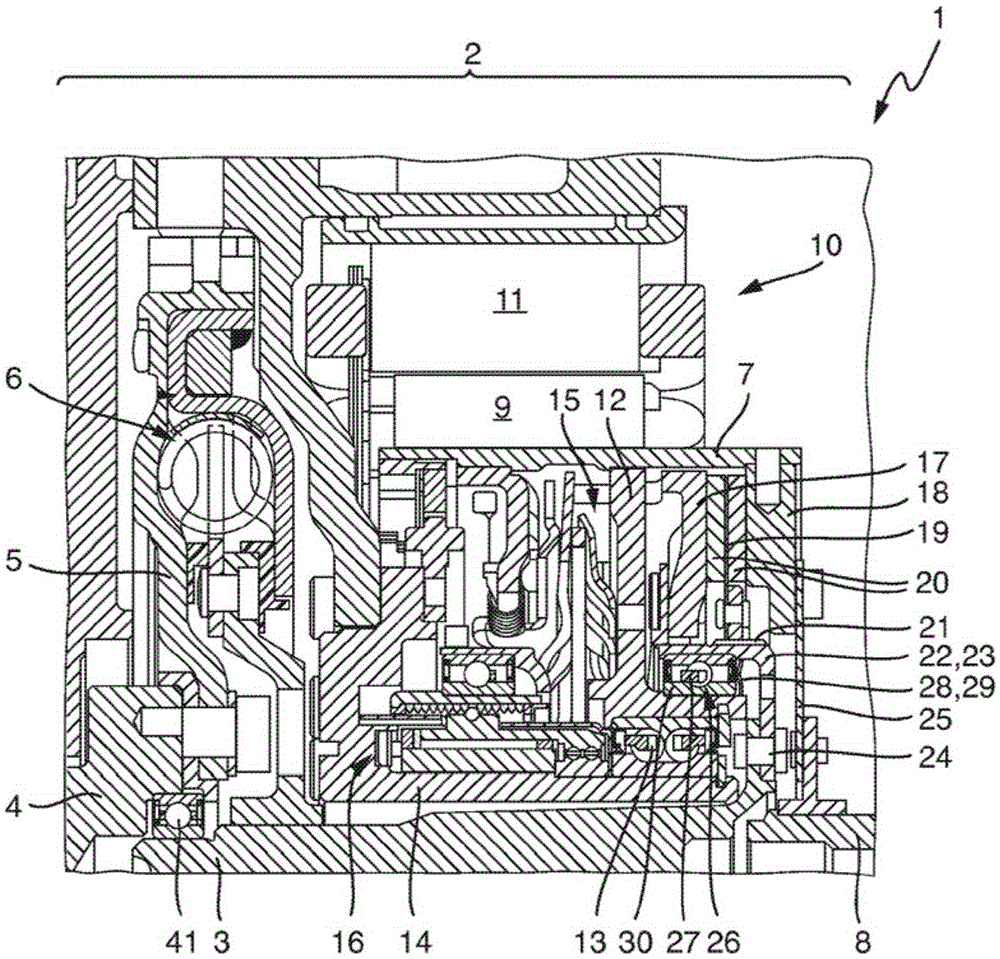

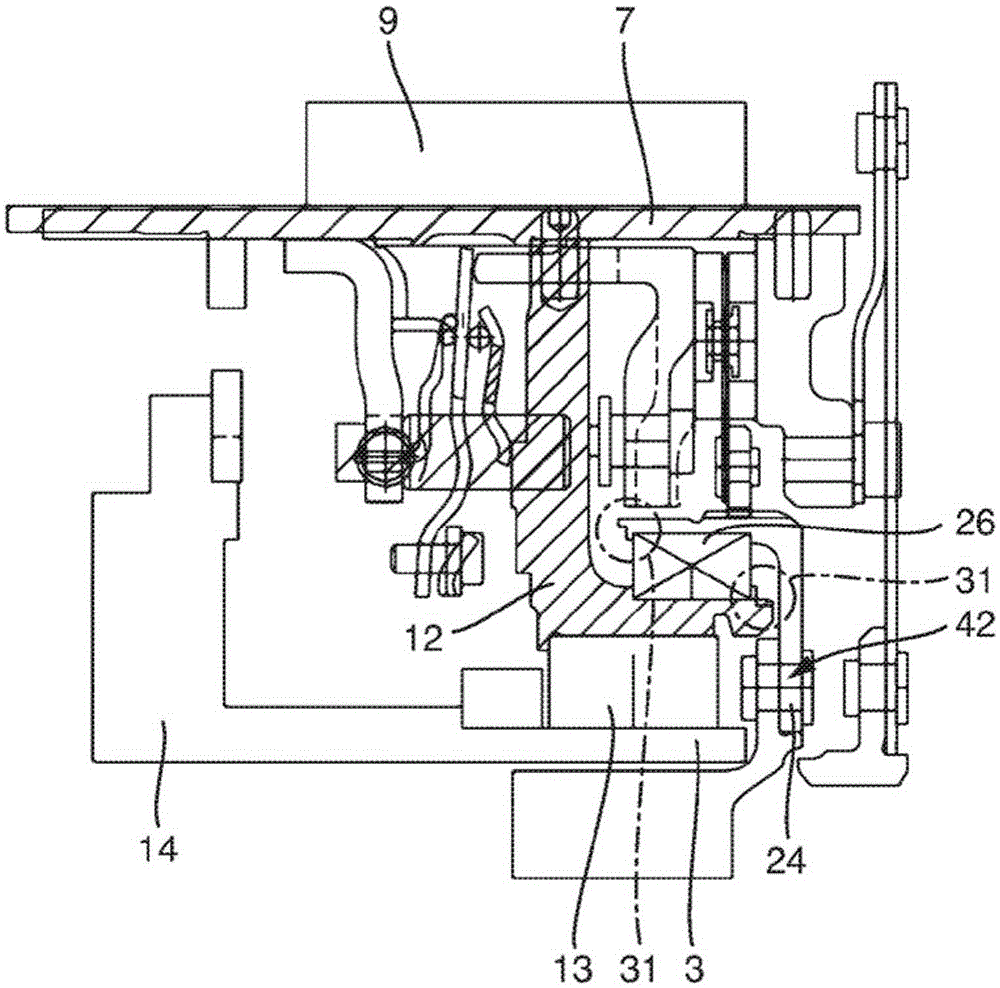

[0037] exist figure 1 shows a separating clutch 1 according to the invention. The separating clutch is used in the hybrid module 2 . The separating clutch 1 and the hybrid module 2 are part of a retrofitted drive train which is used in a motor vehicle, for example a passenger car or a commercial vehicle. The separating clutch 1 contains an intermediate shaft 3 by means of which, optionally interposed with a damping device with a curved spring damper 6 and interposed with a housing 7 , the torque is transferred to The crankshaft driven by the internal combustion engine is transmitted to the transmission input 8 . The housing 7 can have the shape of a tube and is connected to the rotor 9 of the electric motor 10 . The rotor 9 is here set in motion by the force caused by the interaction with the stator 11 .

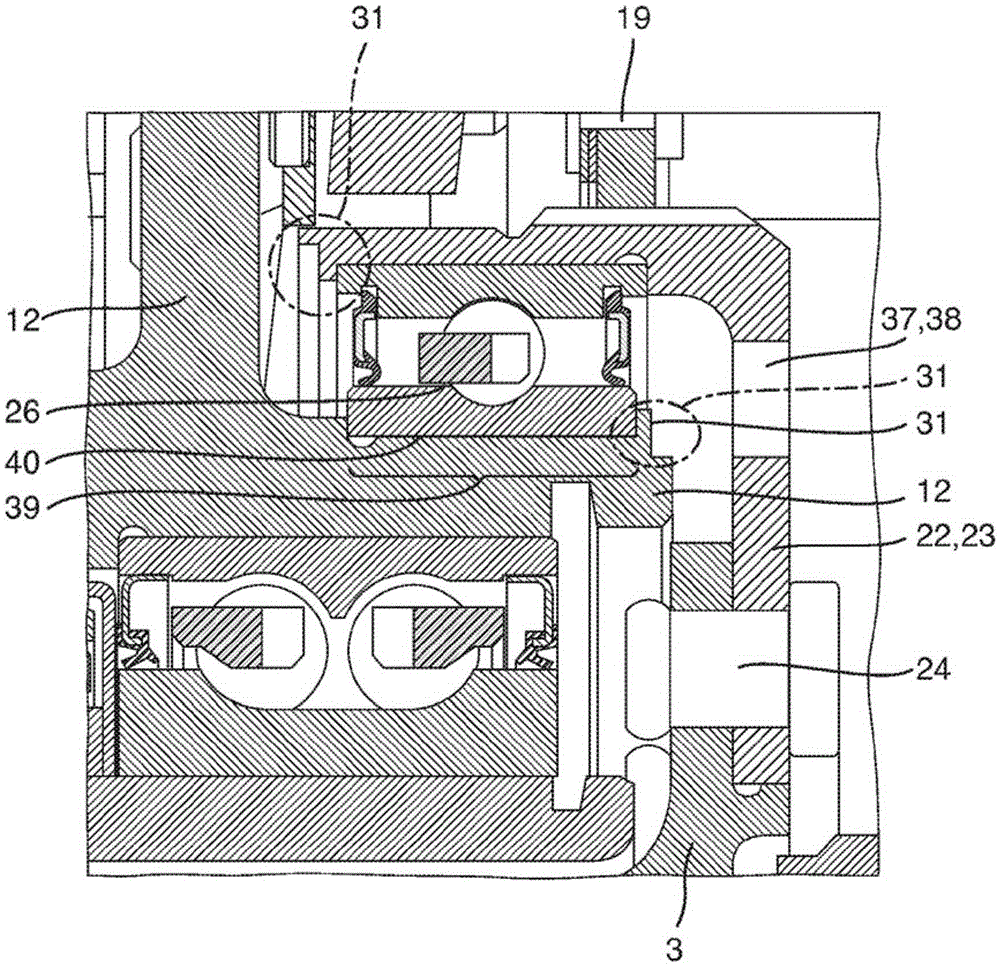

[0038] A radially inwardly protruding central flange 12 is also attached to the housing 7 in a torque-transmitting manner. The central flange 12 is supported on a carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com