Die clamping cylinder seat for die-casting machine

A technology of a clamping cylinder and a die casting machine, applied in the field of die casting machines, can solve the problems of reduced processing quality, poor stability of the clamping cylinder seat, defects in the application of the clamping mechanism, etc., so as to save product cost, improve stability, and be suitable for promotion. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

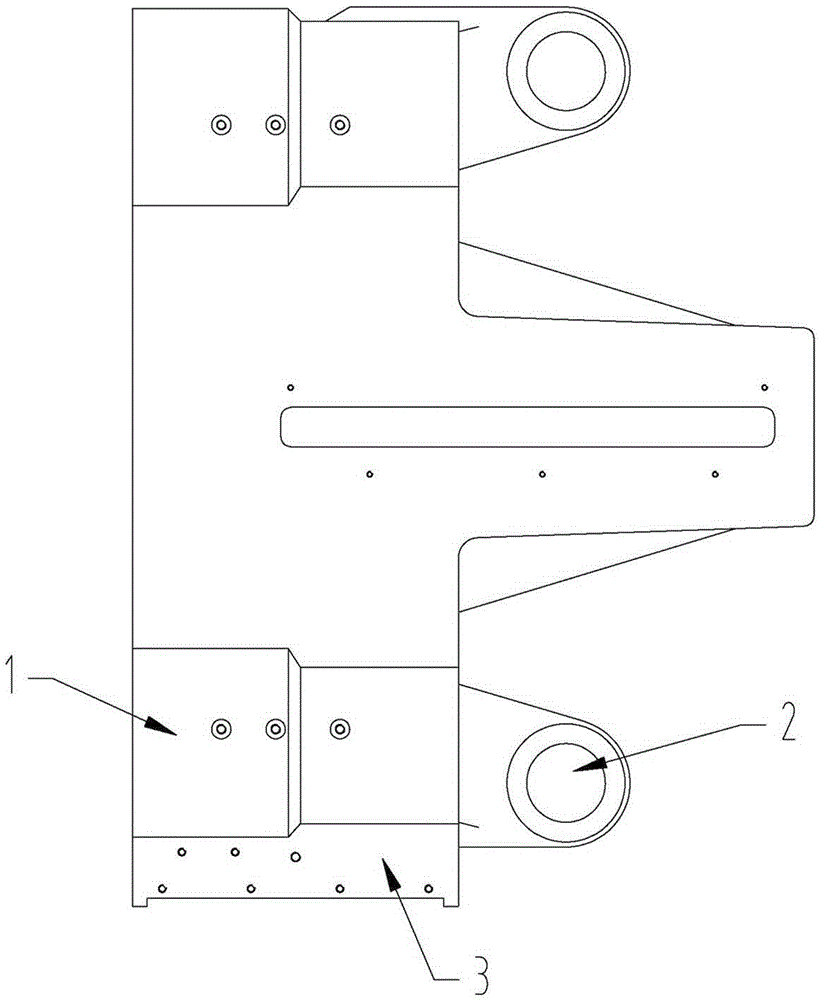

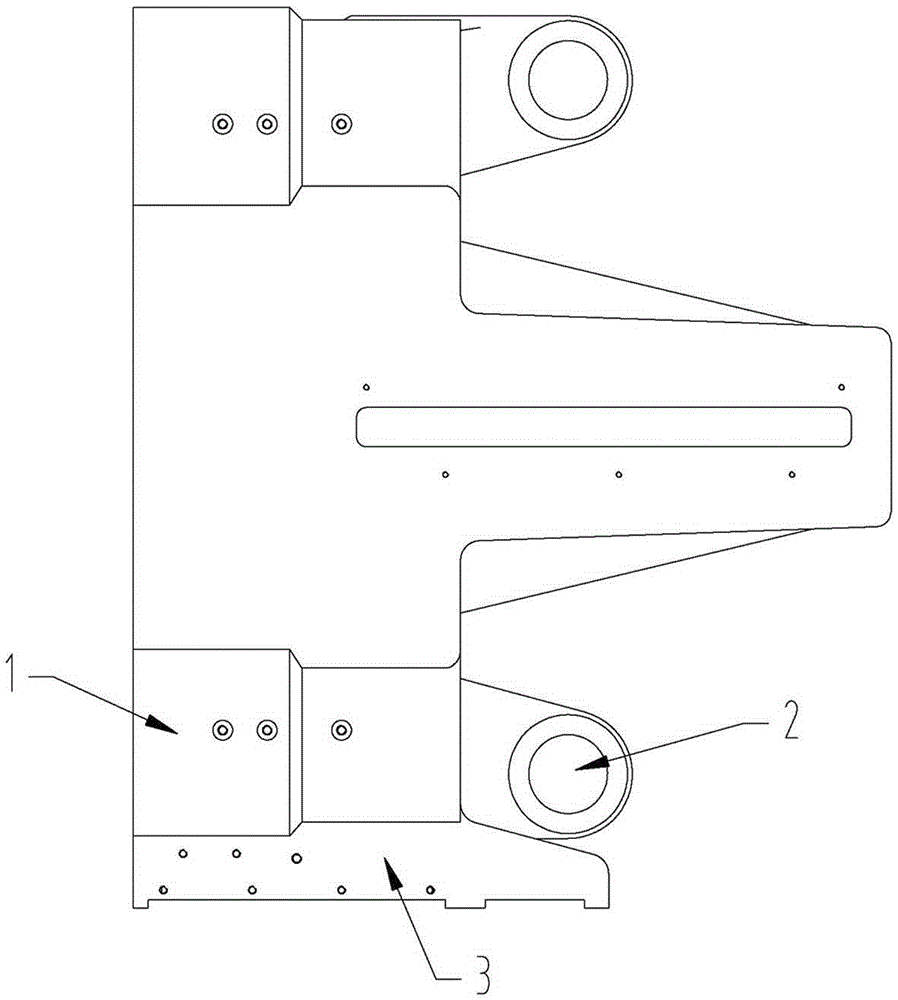

[0014] Such as figure 2 Shown: a mold clamping cylinder block for die-casting machines, including a mold clamping cylinder body 1, a crankshaft hole 2 and a foot 3 are provided on the mold clamping cylinder body 1, and the crankshaft hole 2 is opposite to the mold clamping cylinder body 1 The main body of the base extends outwards, and the width of the foot 3 is greater than the width of the main body of the mold clamping cylinder body 1 to improve the stability of the mold clamping cylinder base. Specifically, the width of the foot 3 is less than the sum of the width of the main body of the mold clamping cylinder body 1 and the width of the extended part of the crankshaft hole 2, and the far end of the foot 3 and the crankshaft hole 2 are far away from the main body of the mold clamping cylinder body 1 The inner cavity walls are on the same vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com