Friction welding phase control method

A phase control and friction welding technology, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of poor phase control accuracy and achieve the effects of ensuring welding quality, improving phase control accuracy, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

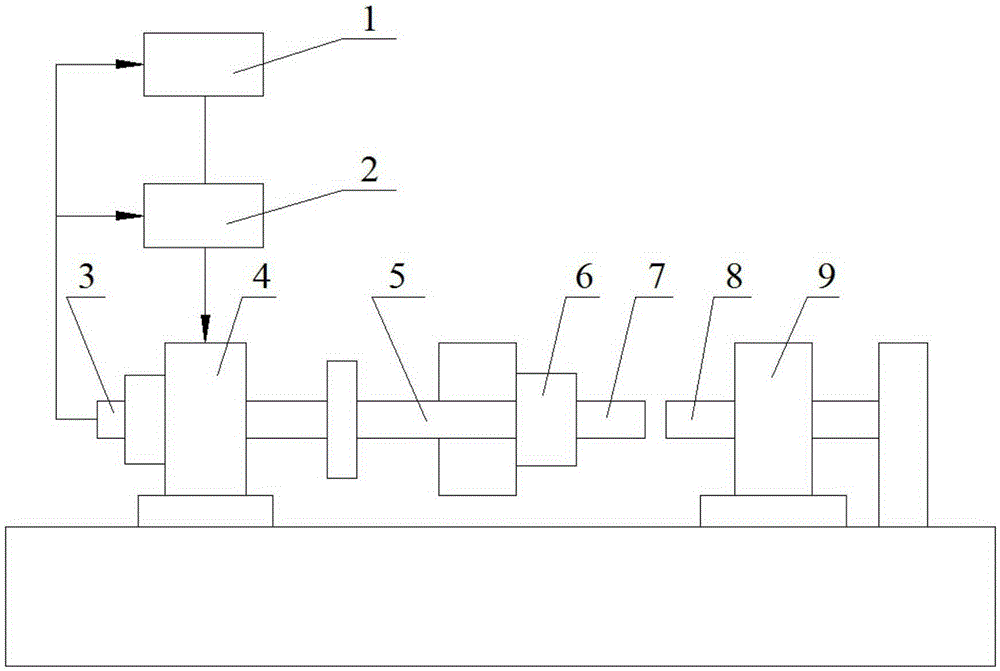

[0016] refer to figure 1 . The specific steps of the friction welding phase control method of the present invention are as follows:

[0017] The computer 1 detects the angular velocity value and angle value of the workpiece 7 at the rotating end through the photoelectric encoder 3. In the phase positioning control stage, the computer 1 outputs the torque value according to the angular acceleration, angular velocity and phase angle of the workpiece 7 at the rotating end and the change rule , flexibly adjust the output current of the DC amplifier 2, drive the DC motor 4 to rotate, control the angular acceleration, angular velocity and phase angle of the workpiece 7 at the rotating end, so that the angular acceleration of the workpiece 7 at the rotating end has no sudden change, the angular velocity decreases to zero smoothly, and the angle Reach the set value to achieve the purpose of precise phase positioning between the workpiece 7 at the rotating end and the workpiece 8 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com