A fully automatic mold moving and pushing device

A pusher device and fully automatic technology, which is applied in the field of hydraulic presses, can solve the problems of high labor intensity in feeding and picking up parts, large one-time investment, and increased costs, and achieve the effects of improving labor efficiency, low cost, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

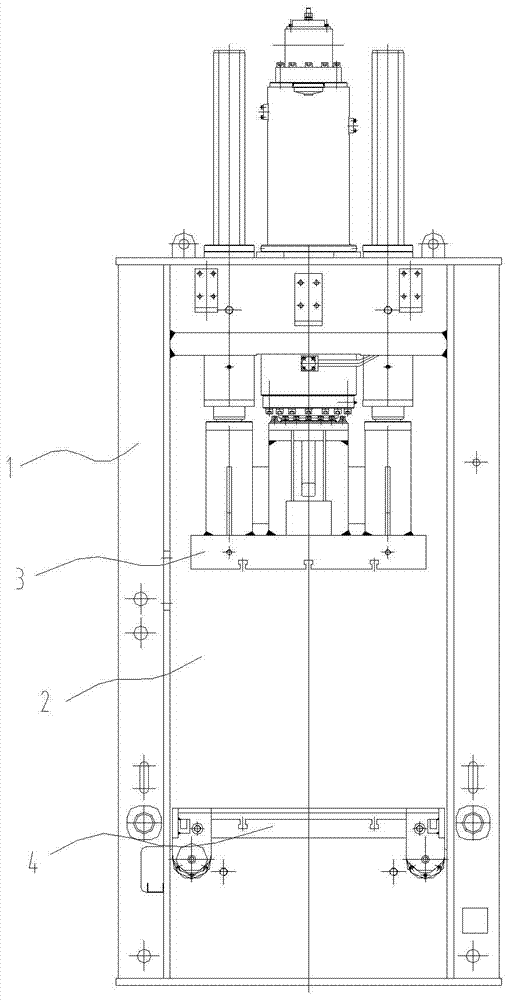

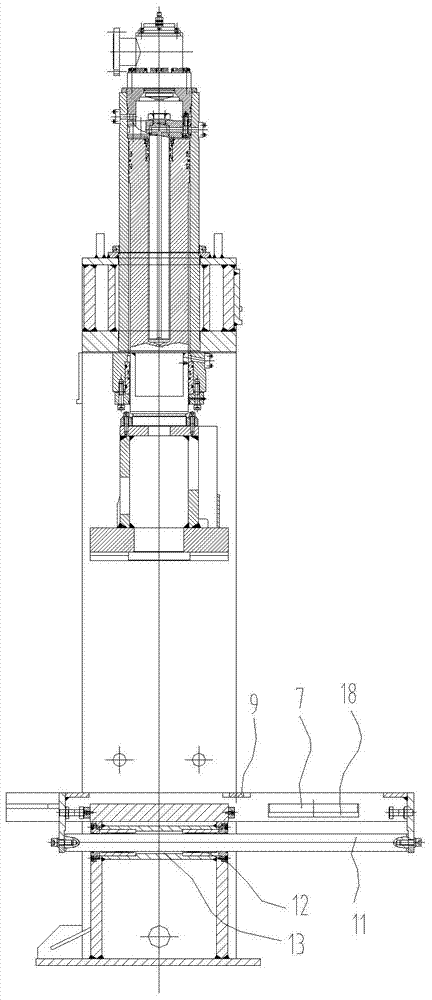

[0028] The present invention as Figure 1-8 As shown, the die-moving pushing device is arranged on a hydraulic press, and the hydraulic press includes a fuselage 1, a cavity body 2 is provided in the middle of the fuselage, and a slide block 3 is provided on the top of the cavity body 2, The lower part is provided with a workbench 4, the slider is used to connect the upper mold, and the workbench is used to place the lower mold 5;

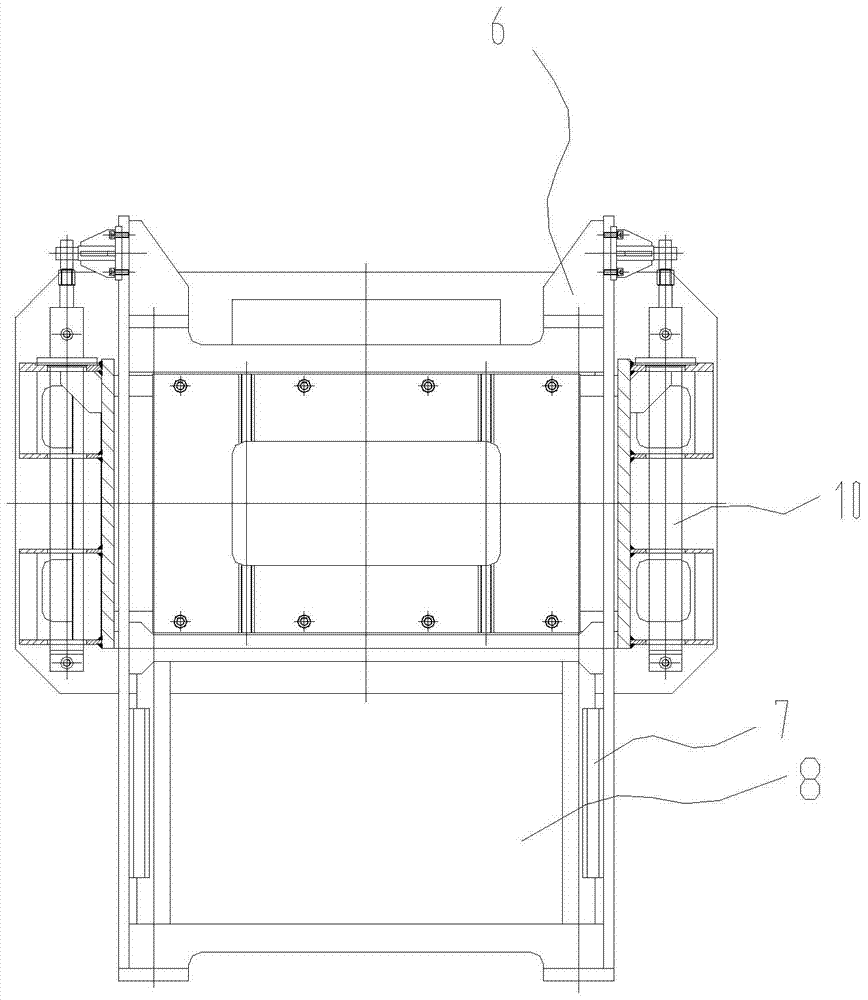

[0029] The mold-moving and pushing device includes a mold-moving and pushing bracket 6 and a mold lifter 7, and the mold-moving and pushing bracket 6 is horizontally and movably connected to the bottom of the cavity body 2, and the mold-moving and pushing bracket 6 has a sliding hole 8. A push rod 9 is provided at the middle top of the slide hole, the bottom surface of the push rod 9 is higher than the top surface of the workbench 4, and the workbench 4 is located in the slide hole 8, the The mold lifter 7 is arranged on the mold-moving push mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com