Sewing machine platen

A sewing machine and table board technology, applied in sewing machine components, sewing equipment, textiles and paper making, etc., can solve the problems of difficult handling, heavy and cumbersome solid wood table board, achieve fast and convenient processing accuracy, reduce the use of wood , processing fast and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

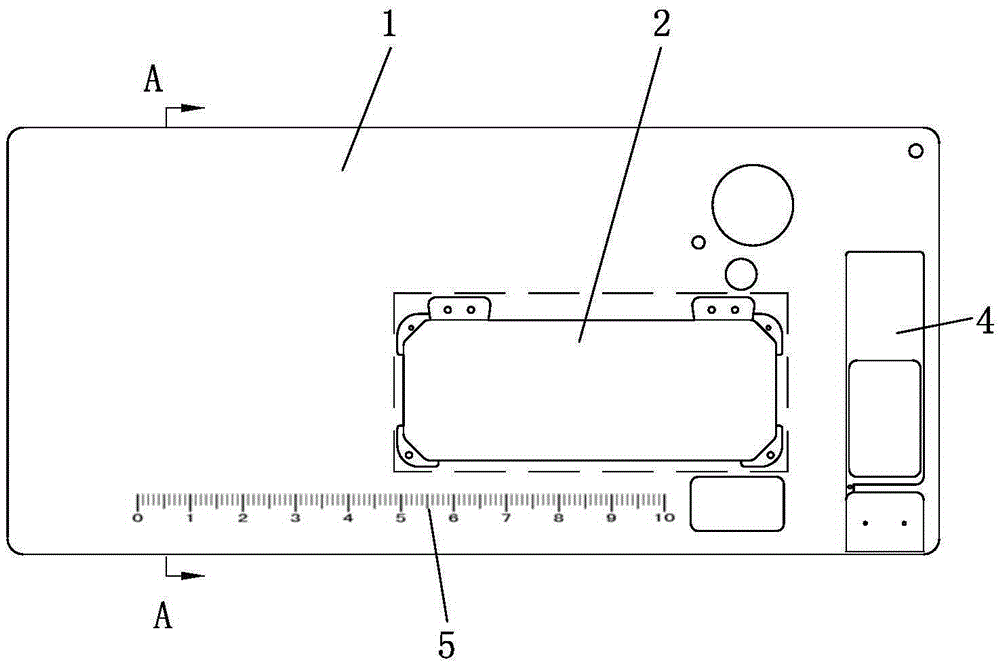

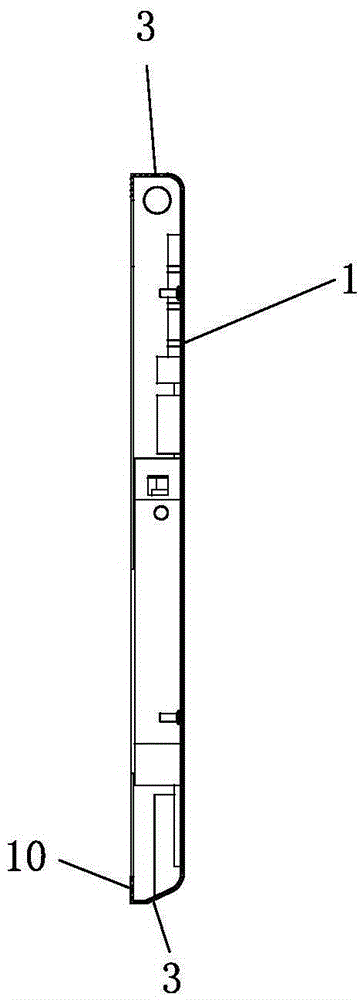

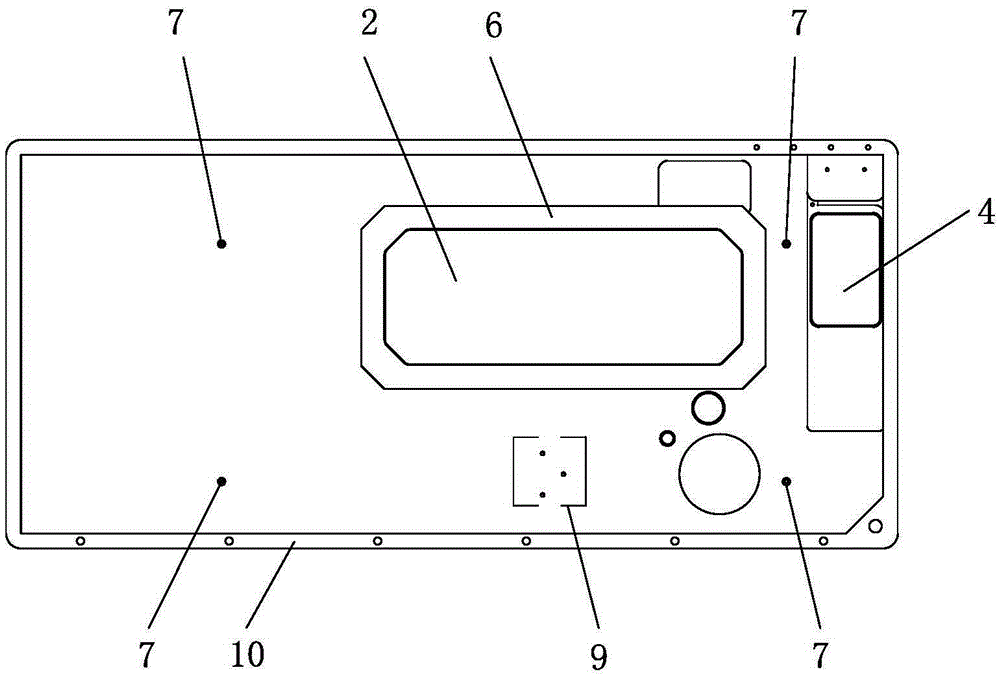

[0026] The present invention will be further described below with specific embodiment, see figure 1 -5:

[0027] A sewing machine table , including a table body 1 made of a metal plate, on which a sewing machine installation position 2 is arranged, and edges 3 are arranged downward around the table body 1 . The metal plate is generally made of steel plate, or other metal plates such as iron plate, using 1-2mm steel plate, the surface of the steel plate has a certain smoothness, and it is made by stamping, bending and other processes.

[0028] In the above technical solution, a scale 5 is provided on the platen body 1 . The scale 5 is set by coating, and the scale 5 can also be fixed on the corresponding position on the platen body 1;

[0029] Or a storage box installation position 4 is provided on the platen body 1; the storage box is arranged in the storage box installation position, and some commonly used tools are placed in the storage box, such as scissors, needles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com