Double-cyclone combustor with primary air distribution structure

A dual cyclone and burner technology, applied in burners, liquid fuel burners, combustion methods, etc., can solve the problems of excessively long flame, easy carbon formation, serious afterburning, etc., so as to improve combustion efficiency and strengthen mixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

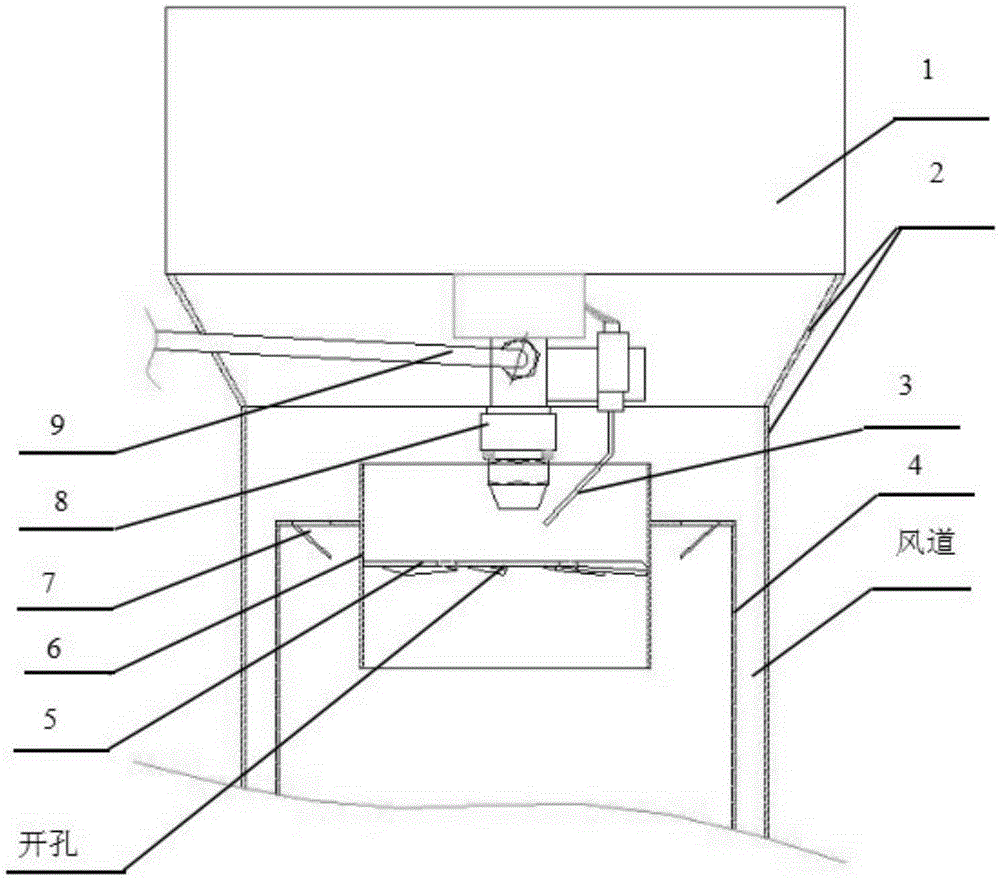

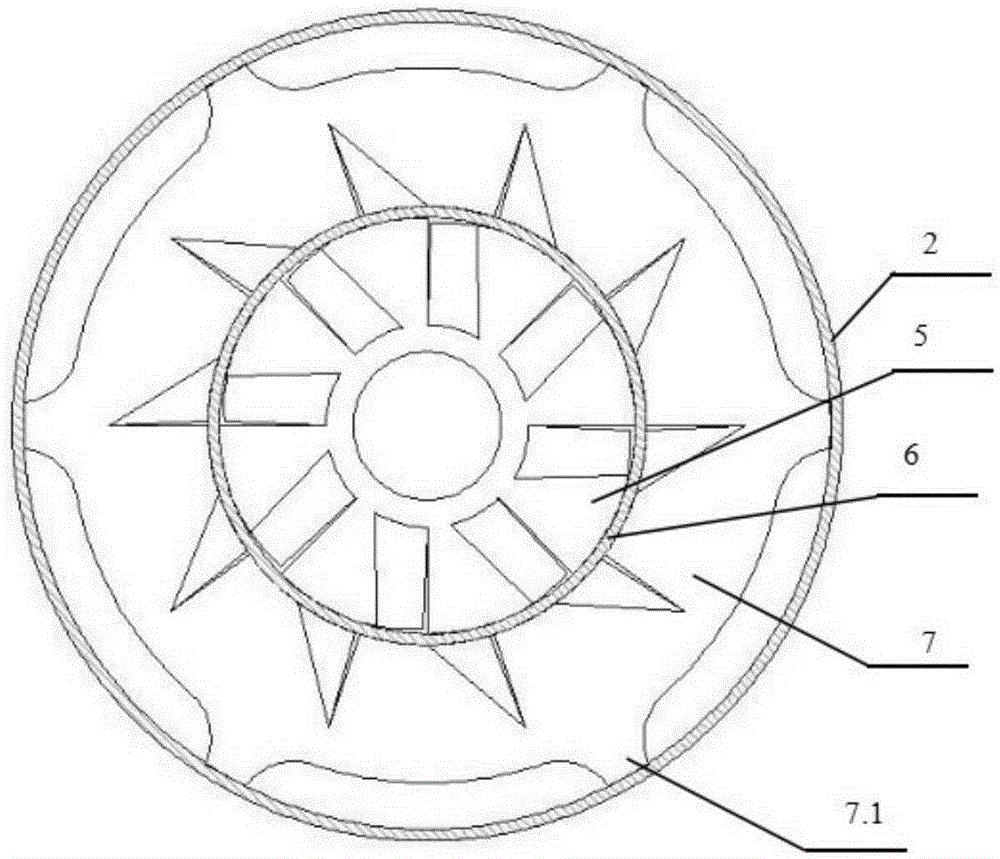

[0017] See figure 1 with figure 2 , a double cyclone type burner with a primary air distribution structure, which is composed of a fan 1, an outer cylinder 2, an ignition mechanism 3, an inner cylinder 4, a cyclone piece, an oil nozzle 8 and an oil passage 9, and the present invention is characterized in that the cyclone The blades are set as inner cyclone blades 5 and outer cyclone blades 7, and the top of the inner cylinder 4 is provided with a wind stabilization cylinder 6 along the axis of the inner cylinder 4 and passing through the inner cylinder 4, and the outer cyclone blades 7 are sleeved on the wind stabilization cylinder. 6 outside, and connected with the outer cylinder 2 through the feet 7.1, the inner cyclone blade 5 is set in the air stabilization cylinder 6; the center of the inner cyclone blade 5 is provided with an opening 5.1; the outer cyclone blade 7 is provided with a foot 7.1 and the fuel injection nozzle 8 is located Inner whirlwind blade 5 openings 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com