Wollastonite enhanced polycarbonate material and preparation method thereof

A technology of polycarbonate and polycarbonate resin, which is applied in the field of plastic processing, and can solve problems such as rough surface, unstable performance of precision instruments, and sensitivity to notches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

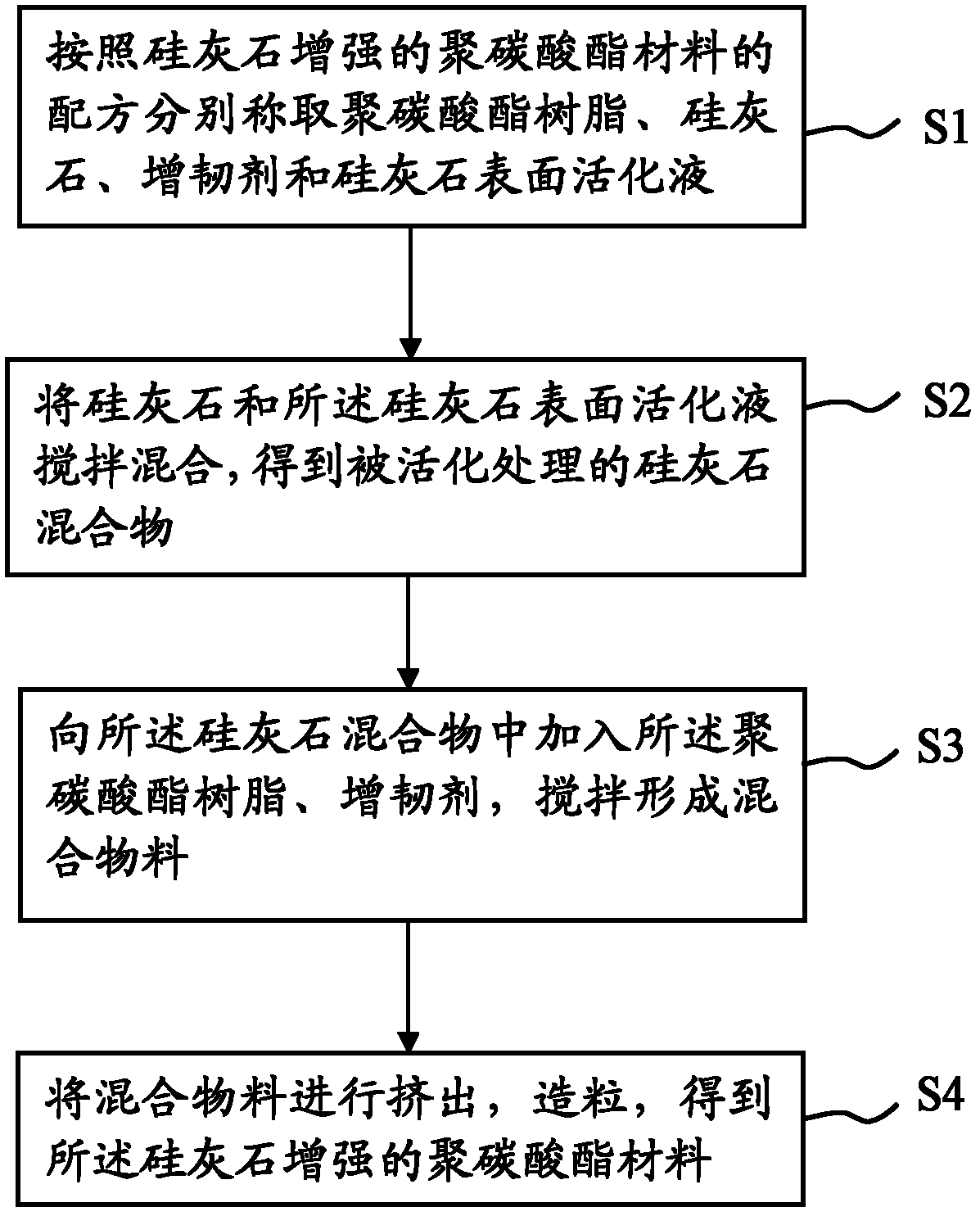

[0029] The embodiment of the present invention also provides a preparation method of the above-mentioned wollastonite-reinforced polycarbonate material, and the process flow is as follows figure 1 shown. The method includes the following steps:

[0030] S1: Weigh out polycarbonate resin, wollastonite, toughening agent and wollastonite surface activation solution according to the formula of the above-mentioned wollastonite-reinforced polycarbonate material;

[0031] S2: stirring and mixing wollastonite and the wollastonite surface activation solution to obtain an activated wollastonite mixture;

[0032] S3: adding the polycarbonate resin and the toughening agent to the wollastonite mixture, and stirring to form a mixture;

[0033] S4: The mixed material is extruded and pelletized to obtain the wollastonite-reinforced polycarbonate material.

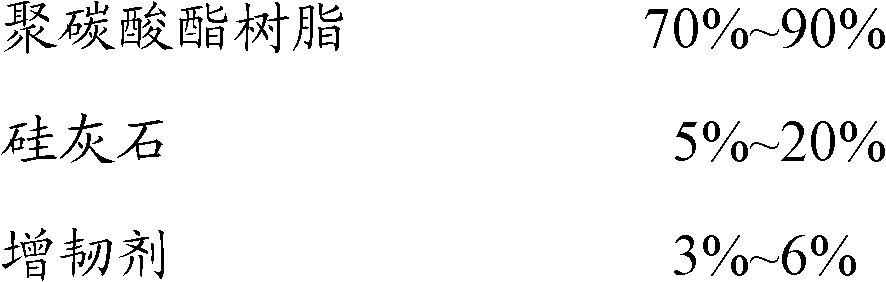

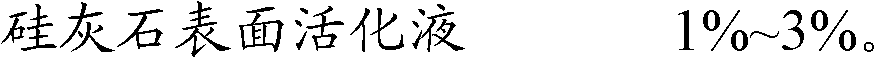

[0034] Specifically, in step S1 of the above-mentioned wollastonite-reinforced polycarbonate material preparation method, the proporti...

Embodiment 1

[0045] The formula components in weight percent of wollastonite reinforced polycarbonate material are as follows:

[0046] The molecular weight is preferably 85% of bisphenol A polycarbonate resin with a molecular weight of 20,000, 8% of wollastonite, 1% of wollastonite surface activation liquid, and 6% of toughening agent for the copolymer of methacrylate and acrylate. Among them, wollastonite has an average aspect ratio of 10, a particle size of 15 μm, and a pH of 7. The wollastonite surface activation solution is 3-aminopropyltriethoxysilane and anhydrous xylene with a volume ratio of 1:1. composed mixture.

[0047] The preparation method of the wollastonite-reinforced polycarbonate material is as follows:

[0048] S11: first put the polycarbonate resin into a drying oven, and dry the polycarbonate resin at a temperature of 120° C. for 3 hours, and then weigh each component according to the formula of the above wollastonite-reinforced polycarbonate material;

[0049] S12:...

Embodiment 2

[0053] The formula components in weight percent of wollastonite reinforced polycarbonate material are as follows:

[0054] The molecular weight is preferably 30,000 molecular weight bisphenol A polycarbonate resin 85%, wollastonite 11%, wollastonite surface activation liquid 1%, methyl methacrylate, butadiene and styrene terpolymer. Copolymer toughener 3%. Among them, the wollastonite has an average aspect ratio of 8, a particle size of 20 μm, and a pH of 7. The wollastonite surface activation solution is composed of γ-glycidyloxypropyltrimethoxysilane and toluene with a volume ratio of 1:1.5. composition of the mixture.

[0055] The preparation method of the wollastonite-reinforced polycarbonate material is as follows:

[0056] S21: first put the polycarbonate resin into a drying oven, and dry the polycarbonate resin at a temperature of 120° C. for 3 hours, and then weigh each component according to the above formula of the wollastonite-reinforced polycarbonate material;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com